Y-axis mounting structure of three-gantry five-axis linkage numerically-controlled milling machine

A five-axis linkage, CNC milling machine technology, applied in the field of milling machines, can solve the problems of low safety and anti-collision coefficient, high cost, poor machining accuracy of large workpieces, etc., and achieve the effect of strong randomness and greatly increased insurance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

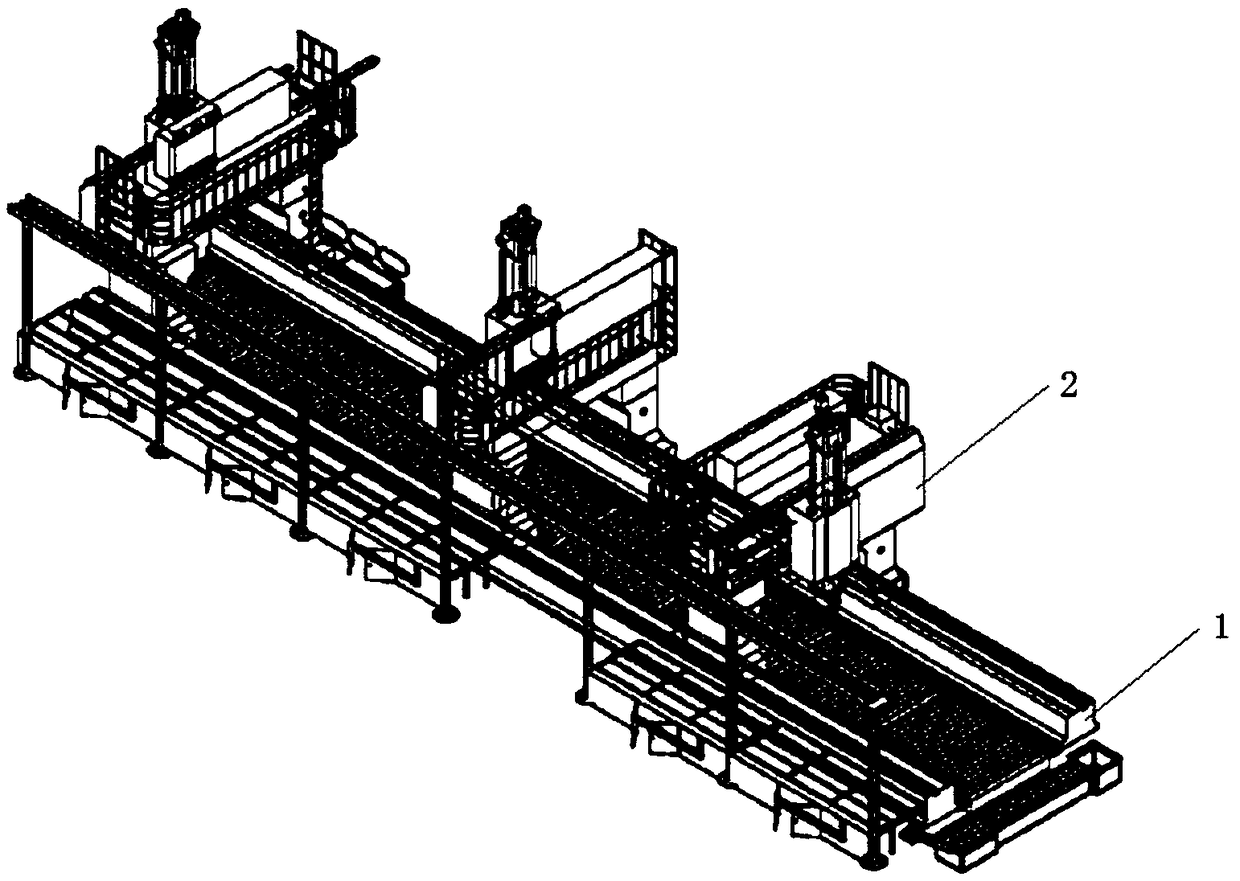

[0053] This embodiment is a high-precision three-gantry five-axis linkage CNC milling machine.

[0054] Refer to attached Figure 1~4, The CNC milling machine includes a base 1, three gantry 2 installed above the base 1 and a numerical control system for driving and controlling the gantry 2. The numerical control system is installed in the numerical control platform cabinet 31 on one side of the milling machine, and the upper part of the numerical control platform cabinet 31 is provided with a wire channel rack 32, on which the electrical circuit and cooling water circuit are installed, and connected to the gantry structure through it, so that the wiring is neat and safe. Each gantry 2 of this embodiment is equipped with its own complete Siemens independent numerical control system, and the three gantry 2 can complete a large workpiece at the same time, and can also complete parts of different sizes respectively; each gantry 2 can use a program to select different It can also...

Embodiment 2

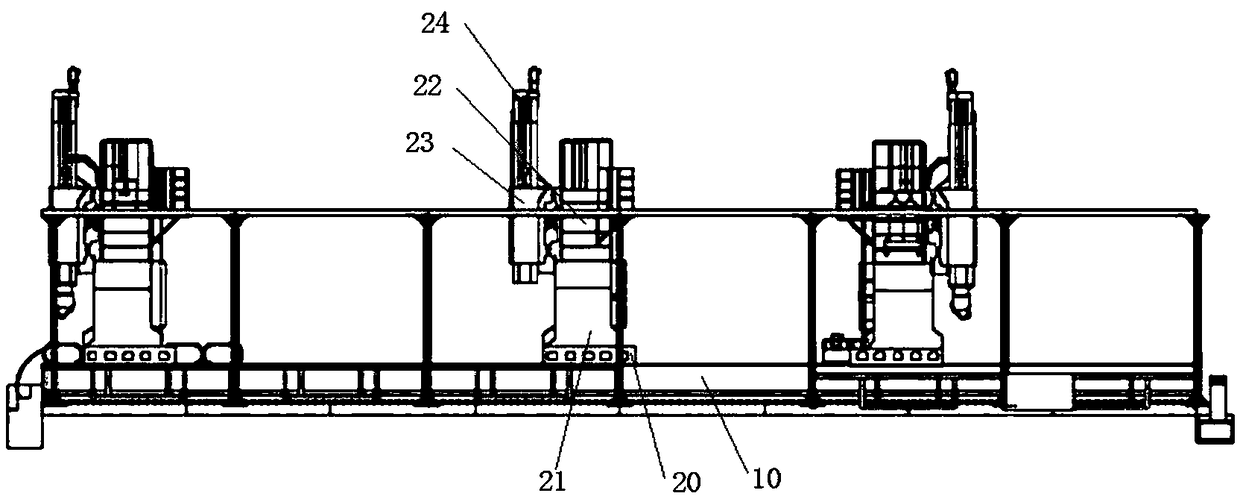

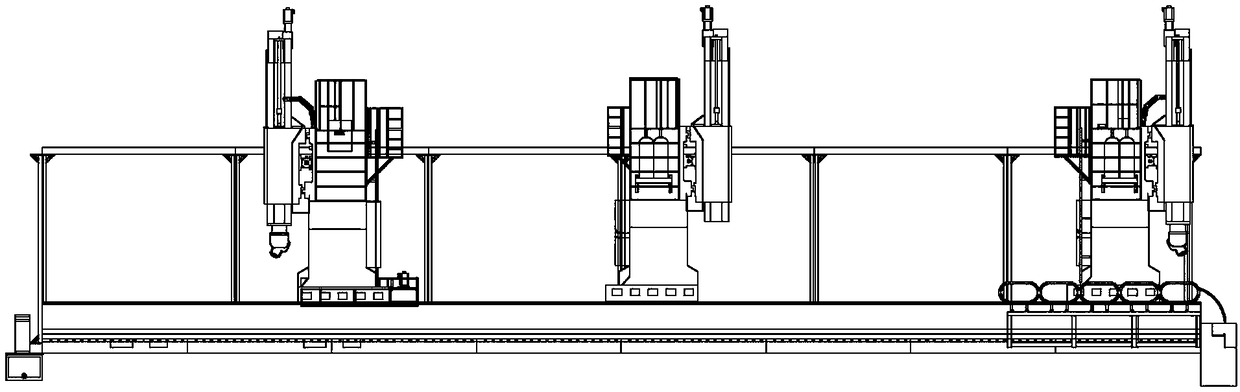

[0065] This embodiment is a three-gantry five-axis linkage CNC milling machine bed 10 structure.

[0066] Refer to attached Figure 5-6 , 20. The bed 10 includes a box-shaped structure and a carriage 20 arranged on it. The box-shaped structure is a three-box structure, which is formed by one-time casting of casting materials and lost foam, and diagonal tie bars are arranged in the box. The top of the box-shaped structure is equipped with left and right sets of racks and grooves, and the grooves are used to accommodate the motor in the gear box. The carriage 20 is connected with the rack through the anti-backlash gear, and the carriage 20 is connected with a gear box. It is connected with the toothed rack, and drives the carriage 20 to slide smoothly on the rack.

[0067] That is, the gear box adopted in this embodiment is a gear box with a double-gear structure, and the gear rack adopts a helical transmission gear rack with a precision of 5 grades and a modulus of 6. The mot...

Embodiment 3

[0076] This embodiment is a Y-axis installation structure of a three-gantry five-axis linkage CNC milling machine.

[0077] Refer to attached figure 1 , the CNC milling machine includes a base 1, a gantry 2 installed thereon and a numerical control system for driving and controlling the gantry 2, the base 1 includes two sets of beds 10 arranged in parallel, forming a five-axis linkage X-axis; the bed 10 There are three gantry 2 installed above, and the workbench 4 is below the gantry 2. Each gantry 2 is equipped with an independent numerical control system, and the contour points of the same positions of each gantry 2 are the same.

[0078] Refer to attached Figure 8-10 The gantry 2 includes a column 21 connected to the bed 10, a beam 22 mounted on the column 21, a ram 23 connected to the beam 22, and a main shaft 24 connected to the ram 23, and a milling head is installed below the main shaft 24. The crossbeam 22 constitutes the Y-axis of five-axis linkage, and the ram 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com