Fixing device for three-way valve machining

A technology for fixing devices and three-way valves, which is applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve problems such as irregular valve contour tracks, difficult to fix different types of products, and various sizes of three-way valves, etc., to achieve structural Reasonable design, compact layout and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

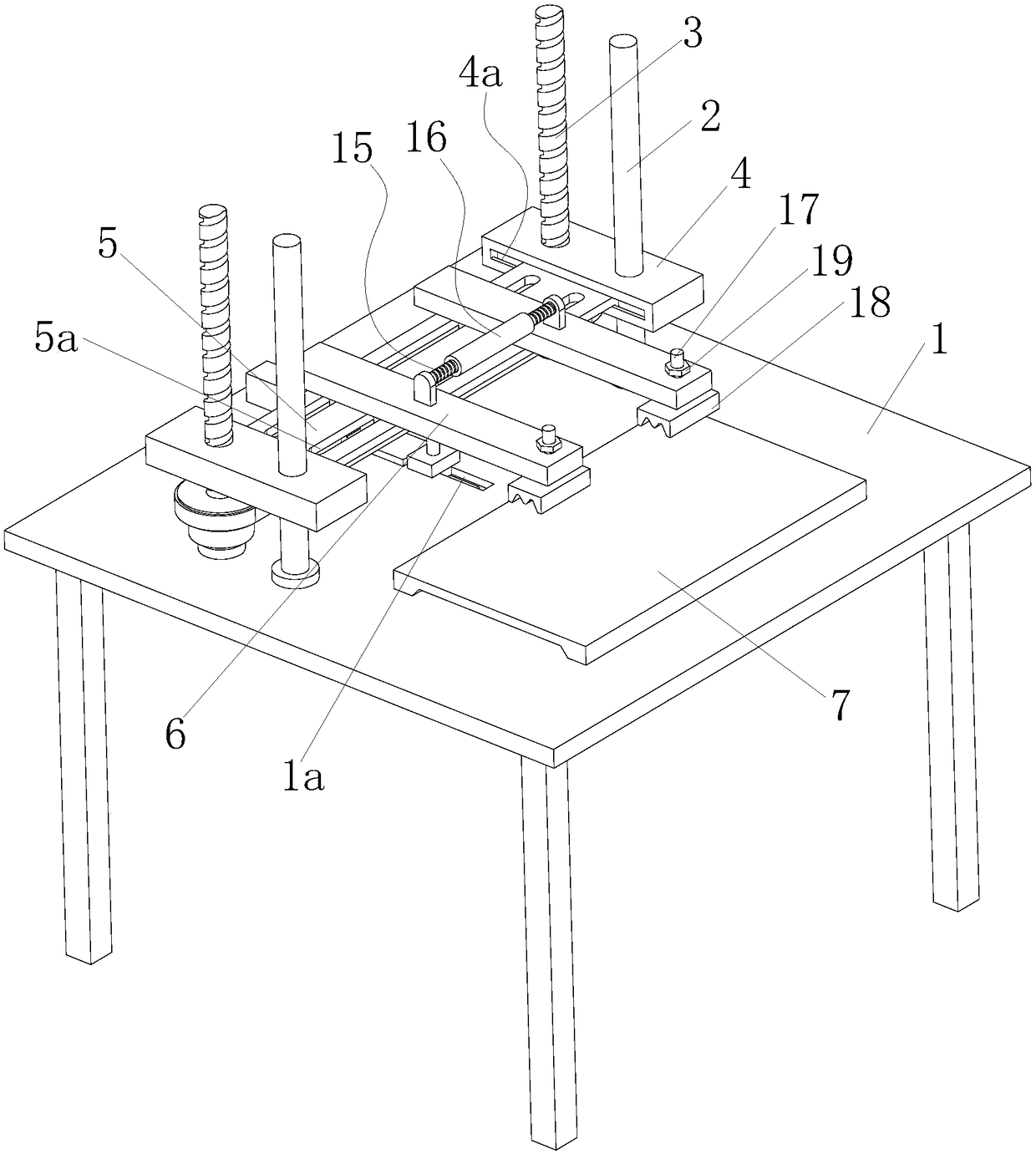

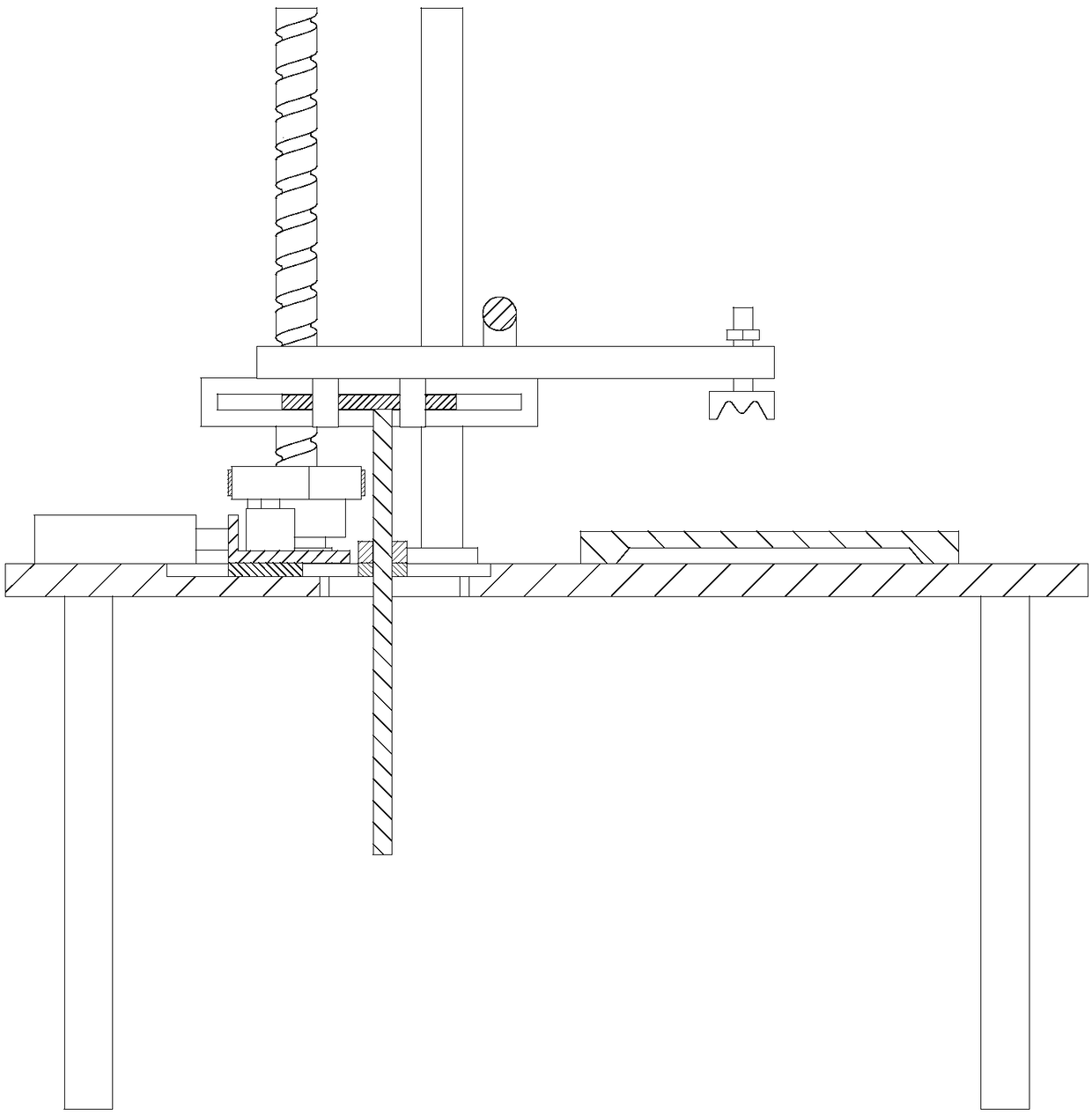

[0020] Such as Figure 1 to Figure 3 As shown, a fixing device for three-way valve processing includes a mounting table 1, a guide strut 2 is fixed on the left side and a right side of the mounting table 1, and a lead screw 3 is rotatably connected, and the guide strut 2 A load-bearing platform 4 is installed together with the lead screw 3, and a longitudinal shift plate 5 is slid on the load-bearing platform 4 along its own length direction, and two pressing plates 6 are slid on the longitudinal shift plate 5 along its own length direction. A positioning plate 7 fixed on the mounting table 1 is provided under the free end of 6 .

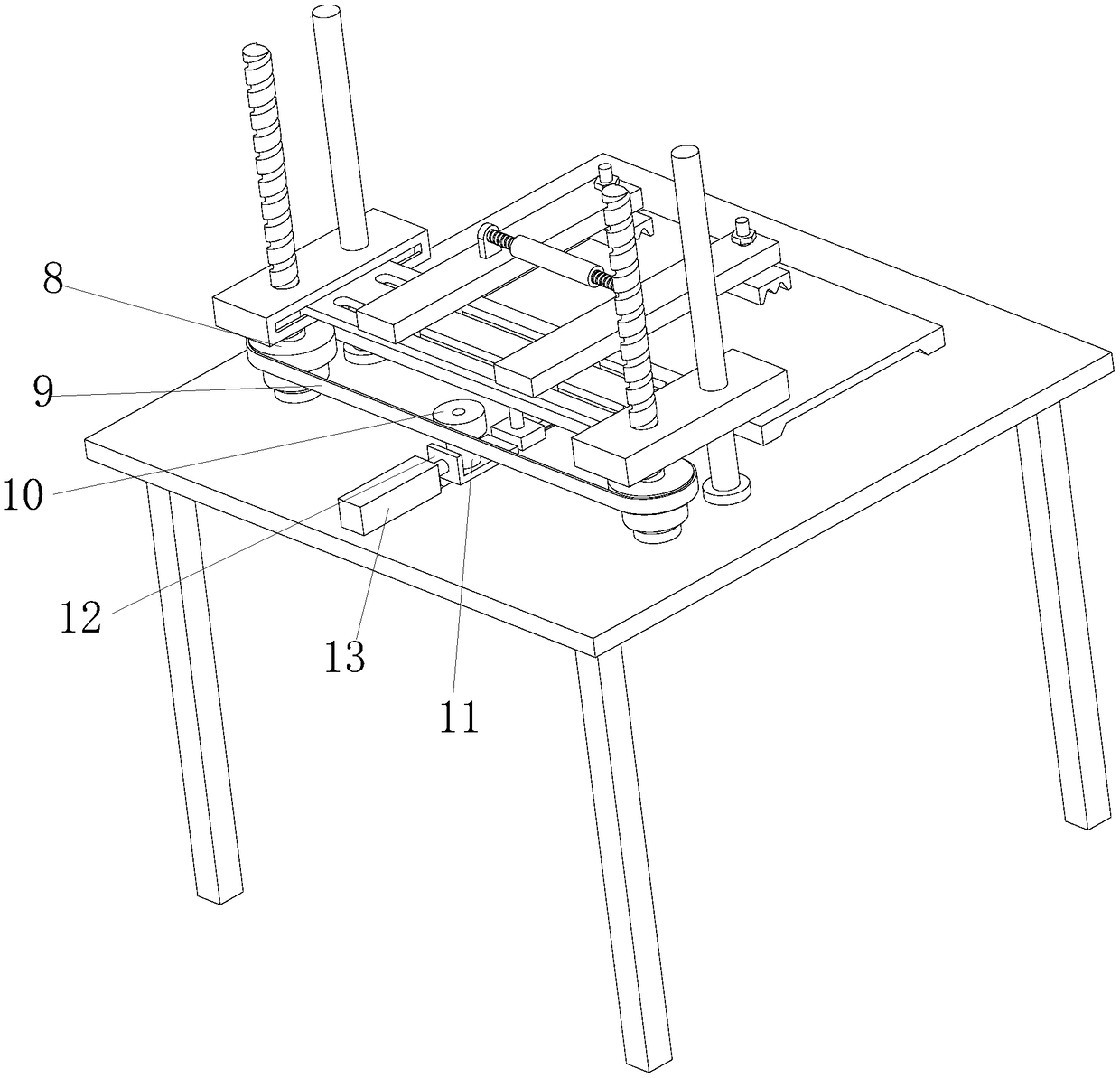

[0021] Belt pulley 8 is all installed on the leading screw 3 of left side and right side, and belt 9 is housed jointly on the belt pulley 8 of left side and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com