Full-automatic punching machine

A punching machine, fully automatic technology, applied in metal processing and other directions, can solve problems such as low punching efficiency, and achieve the effect of improving punching efficiency, intelligent full automation, and improving punching speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

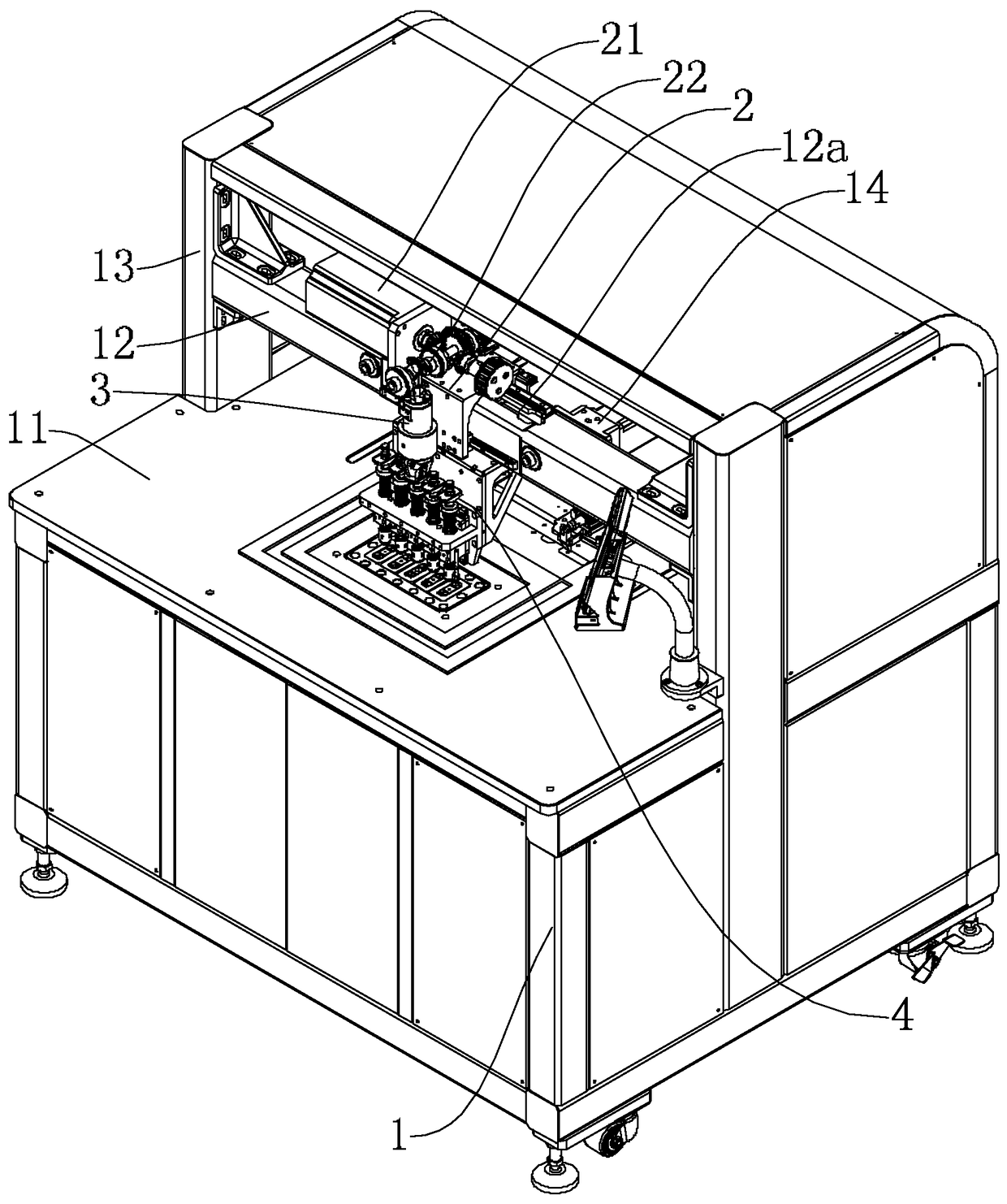

[0027] Such as figure 1 As shown, the frame structure of the punching machine of the present invention includes a frame 1 with a working surface 11 . A cross arm 12 for installing the punching mechanism is arranged above the work surface 11 , and both ends of the cross arm 12 are fixedly connected with the frame 1 through support arms 13 .

[0028] The cross arm 12 is provided with a driving mounting seat 2 which can move linearly along the cross arm 12, and the driving mounting seat 2 is provided with a punching knife connecting seat 3 which is driven by a punching power motor 21 and can move up and down. A punching knife mounting base 4 fixedly connected to the cross arm 12 is provided below the driving mounting base 2 , and at least two punching knife mounting rods 41 arranged side by side are arranged on the punching knife mounting base 4 . The lower end of each punching knife mounting rod 41 can be connected with a punching knife 45 for punching holes of various styles. ...

Embodiment 2

[0065] Such as Image 6 with Figure 7 Shown is another embodiment of the punching knife connection structure. In this embodiment, the punch connection structure also includes an interface seat 32 capable of connecting and detaching from the punch installation rod 41 , and the interface seat 32 is provided with two claws 33 capable of engaging both sides of the punch installation rod 41 . A connecting cylinder 34 is provided on the punching knife connecting seat 3 to drive the claw 33 to rotate to realize the engaging or releasing action.

[0066]The jaw 33 has a rotating portion 33a that is rotatably connected to the punching knife connecting seat 3 through a rotating shaft 35 , an engaging portion 33b that rotates around the rotating shaft 35 to open and close, and a cylinder connecting portion 33c that drives the claw 33 to rotate.

[0067] A groove 34a is formed at the end of the driving rod connected to the cylinder 34, and the cylinder connecting portion 33c is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com