Band saw numerical control four-tooth stamping machine

A gear punching machine and band saw technology, applied in the field of band saw CNC four-tooth gear punching machine, can solve the problems of band saw material slippage, large mold loss, high production cost, etc., achieve accurate tooth pitch, improve production efficiency, and improve punching The effect of tooth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

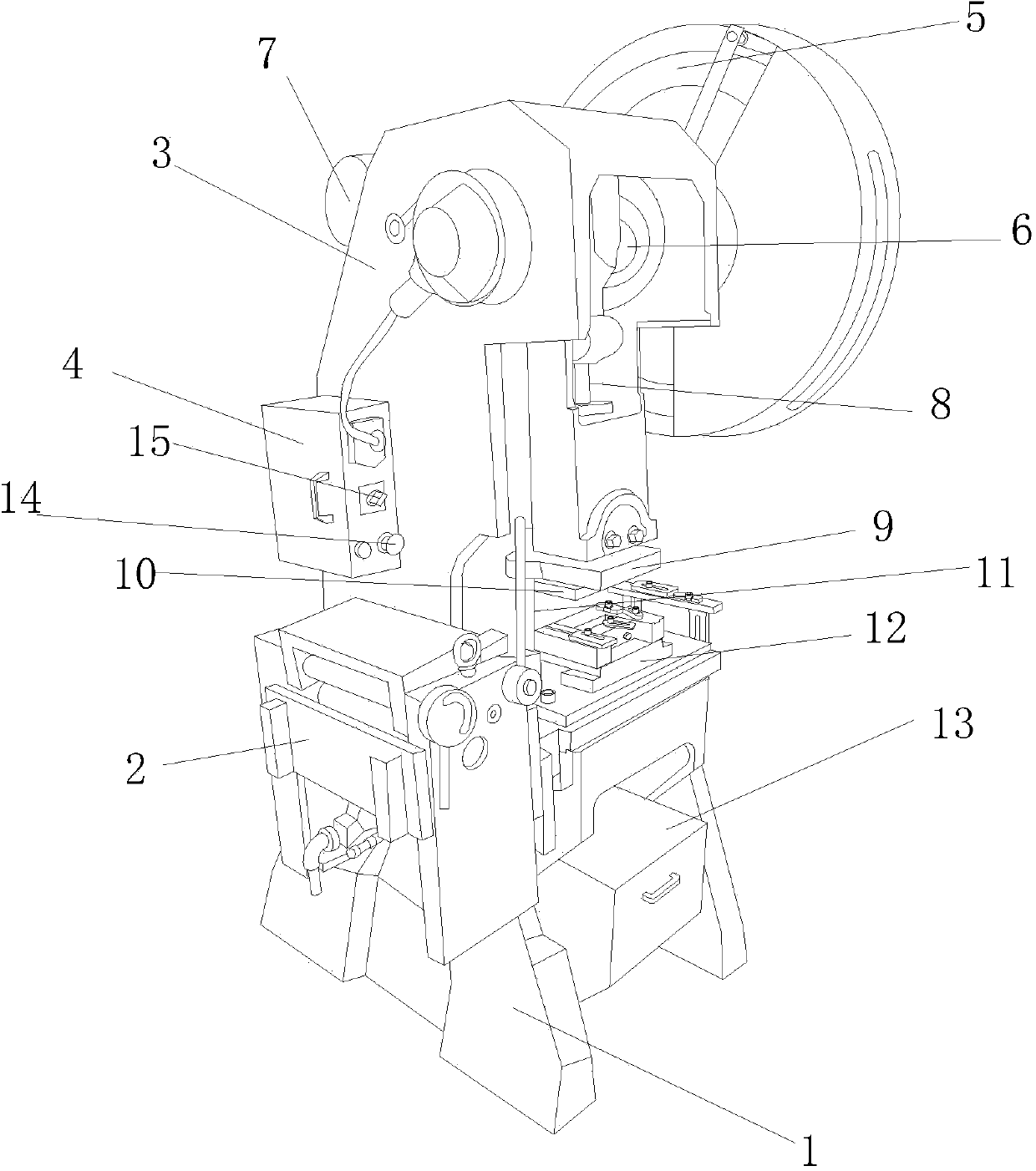

[0015] Such as figure 1 As shown, a band saw CNC four-tooth punching machine includes a CNC machine 1, a traction device 2 is provided on the left side of the CNC machine 1, and a CNC stamping support arm 3 is provided on the rear side of the CNC machine 1. One side of the support arm 3 is provided with an electric control box 4, and the other side of the CNC stamping support arm 3 is provided with a stamping gravity wheel 5, and the transmission shaft 6 of the stamping gravity wheel 5 is penetrated into the CNC stamping support arm 3, and is connected with the transmission The output shaft of the motor 7 is connected, and the middle part of the transmission shaft 6 extends vertically downwards to a pushing shaft 8. The end of the pushing shaft 8 is provided with an upper die mounting plate 9, and the lower end of the upper die mounting plate 9 is provided with an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com