Safe punch magnetic feeder

A safe feeder technology, which is applied in the field of mechanical stamping, can solve the problems of low-cost feeder stamping parts, inconvenient construction operations for workers, and affecting the production progress of workpieces, etc., to reduce the friction coefficient, easy to replace, and convenient to replace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

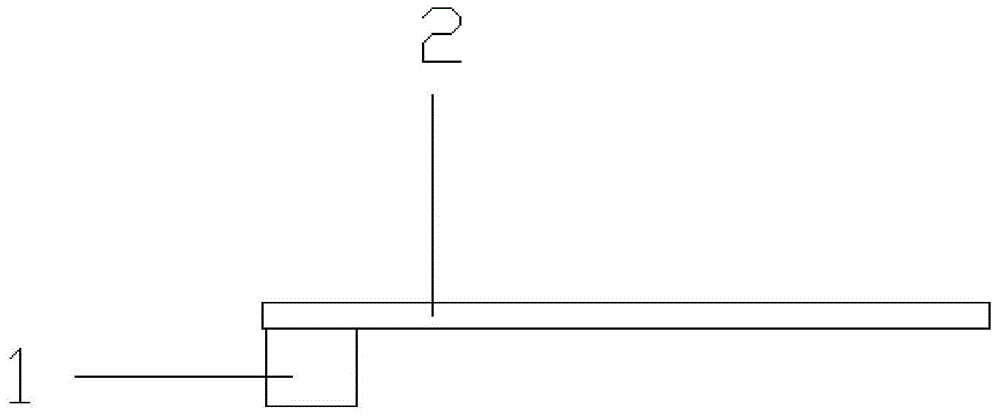

[0033] Such as Figure 1 to Figure 3 The shown magnetic feeder for a safety punching machine includes a permanent magnet 1 and a stick 2. The stick 2 is a wooden stick with a length of 200±10mm, including an A end and a B end, wherein the A end of the stick 2 is rectangular, and the bottom A permanent magnet 1 is installed; wherein the end B of the stick 2 is cylindrical.

[0034] The A end of the stick 2 can also be "fork-shaped" or "hook-shaped".

[0035] The permanent magnet 1 is cylindrical.

[0036] The permanent magnet 1 and the stick 2 are bonded by adhesive.

[0037] The upper surface of the stick 2 is sprayed with carbon nano-coating.

[0038] Described stick 2 can be changed into steel according to the demand of actual production.

[0039] The operation method of a safe type magnetic feeder for a punch press includes the following steps of bonding the permanent magnet 1 to the lower die of the punch press, the worker holds the end B of the stick 2 with the palm o...

Embodiment 2

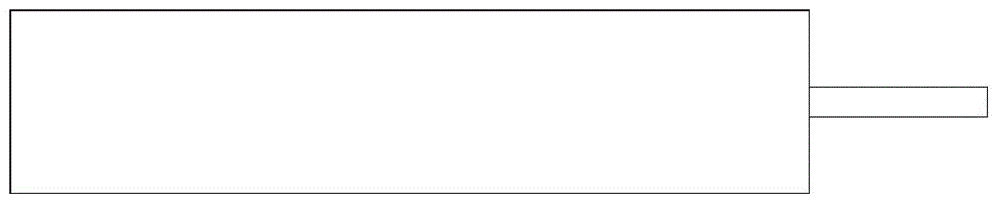

[0041] Such as Figure 4 The shown magnetic feeder for a safety punching machine includes a permanent magnet 1 and a stick 2. The stick 2 is a wooden stick with a length of 200±10mm, including an A end and a B end, wherein the A end of the stick 2 is rectangular, and the bottom A permanent magnet 1 is installed; wherein the end B of the stick 2 is cylindrical.

[0042] The A end of the stick 2 can also be "fork-shaped" or "hook-shaped".

[0043] The permanent magnet 1 is cylindrical.

[0044] The permanent magnet 1 and the stick 2 are bonded by adhesive.

[0045] The upper surface of the stick 2 is sprayed with carbon nano-coating.

[0046] Described stick 2 can be changed into steel according to the demand of actual production.

[0047] The stick 2 is connected with the permanent magnet 1 at an included angle of 15° to 30° with the horizontal direction.

[0048] The operation method of a safe type magnetic feeder for a punch press includes the following steps of bonding ...

Embodiment 3

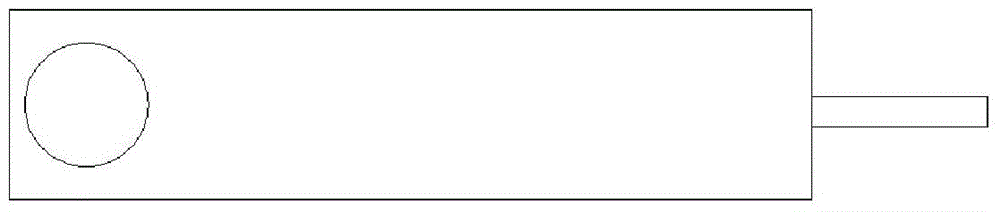

[0050] Such as Figure 5 The shown magnetic feeder for a safety punching machine includes a permanent magnet 1 and a stick 2. The stick 2 is a wooden stick with a length of 200±10mm, including an A end and a B end, wherein the A end of the stick 2 is rectangular, and the bottom A permanent magnet 1 is installed; wherein the end B of the stick 2 is cylindrical.

[0051] The A end of the stick 2 can also be "fork-shaped" or "hook-shaped".

[0052] There is a groove in the middle of the described stick 2 .

[0053] The permanent magnet 1 is cylindrical.

[0054] The upper surface of the stick 2 is sprayed with carbon nano-coating.

[0055] Described stick 2 can be changed into steel according to the demand of actual production.

[0056] The permanent magnet 1 and the stick 2 are bonded by adhesive.

[0057] The operation method of a safe type magnetic feeder for a punch press includes the following steps of bonding the permanent magnet 1 to the lower die of the punch press, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com