Surface color development and weaving method of single-color warp and multi-color weft woven fabrics

A multi-color weft and woven fabric technology, applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of enterprise production efficiency, many processes, and increased design difficulty, so as to reduce the influence of brightness and color, and improve weaving. Efficiency, the effect of simplifying the weaving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

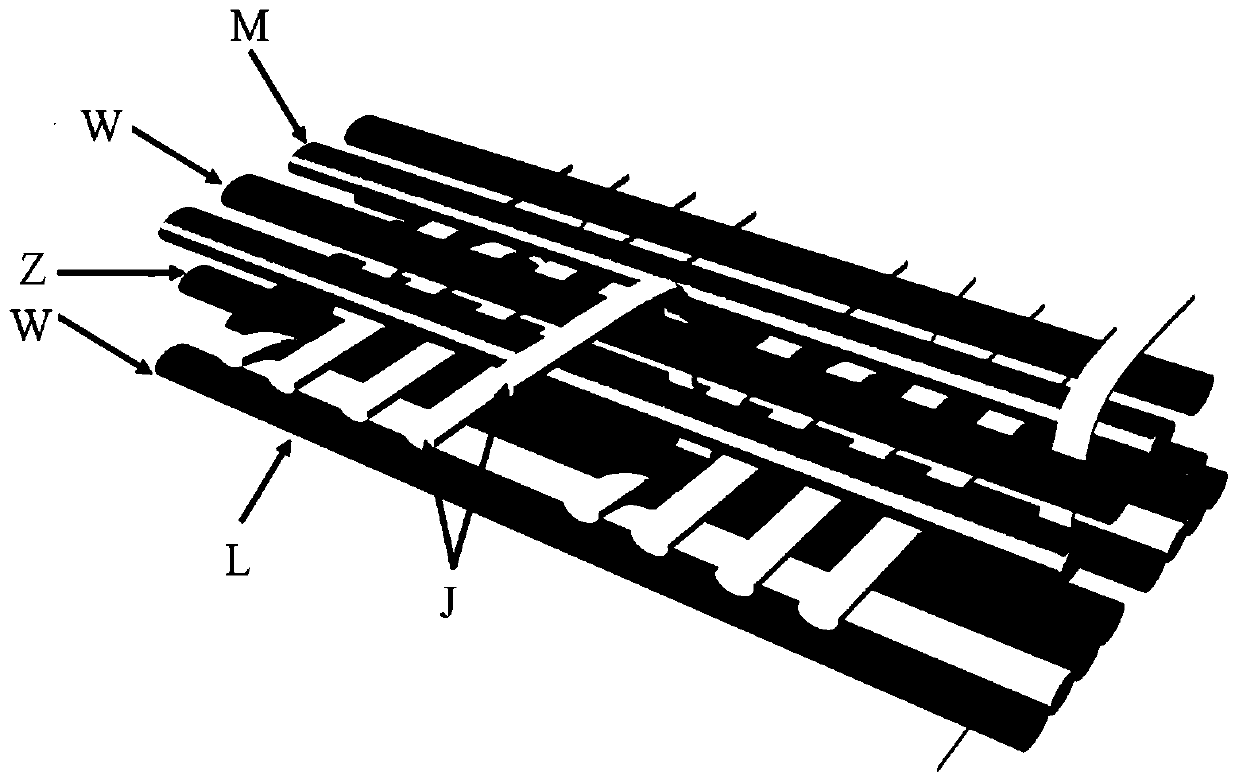

[0046] As mentioned in the background technology, in the developed colored jacquard fabrics, more color is developed by using multi-color warp, multi-color weft, multi-color warp and single-color weft, and its color development method is expressed by the color of warp and weft yarns. The color of the fabric, through the interweaving of warp and weft yarns of various colors, forms a colored jacquard fabric. However, this weaving method has a series of problems such as high warp yarn exposure which affects the surface brightness and color saturation of the fabric, high production cost, low efficiency, and difficult design.

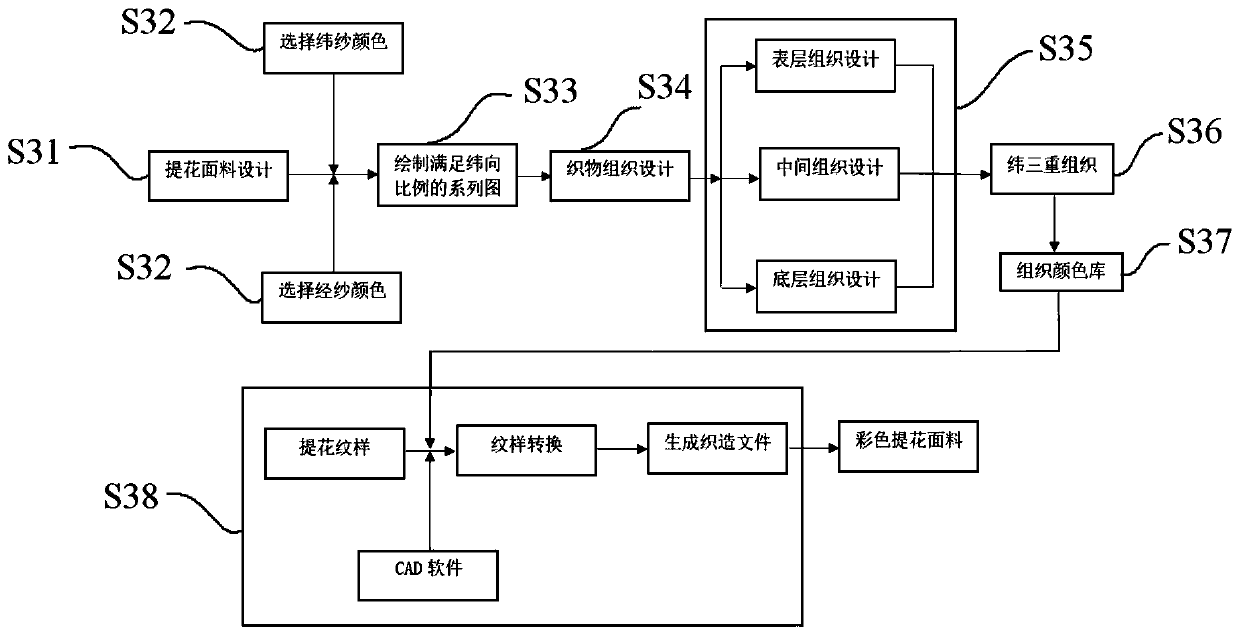

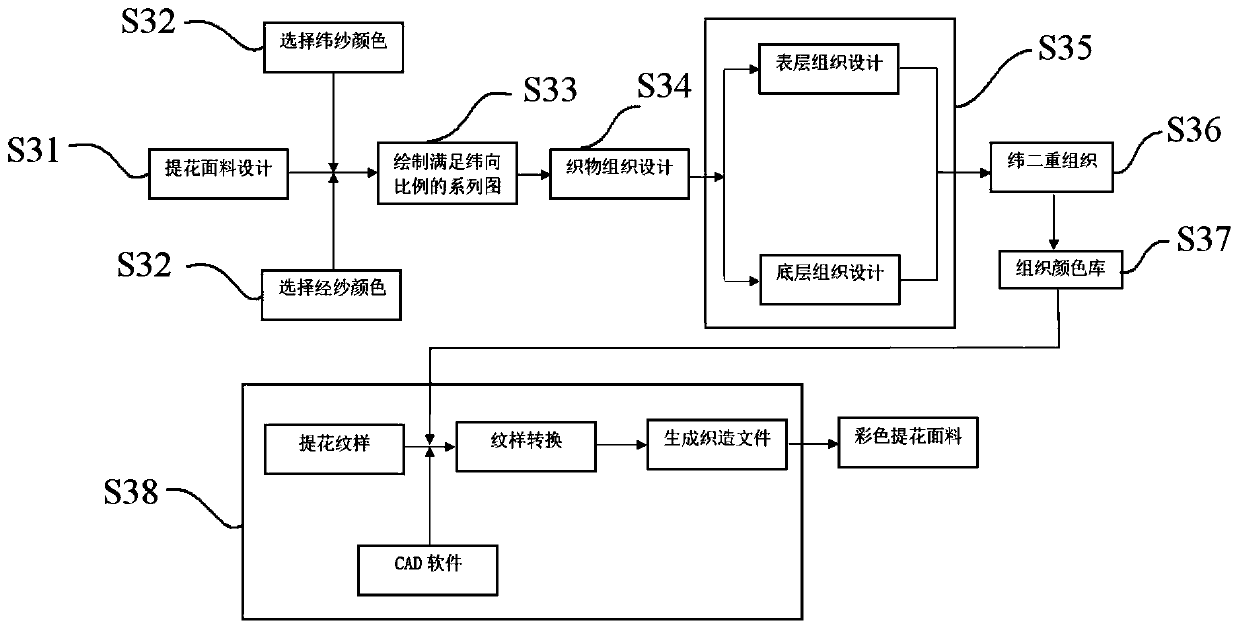

[0047] In view of the above technical problems, the present invention provides a surface color development and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com