Printing and dyeing straight roller mercerizing machine alkali liquor reusing device and using method thereof

A technology of multiplexing device and mercerizing machine, which is applied in the fields of mercerizing, equipment configuration for processing textile materials, textiles and papermaking, etc., which can solve the problems of lye waste, low efficiency, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

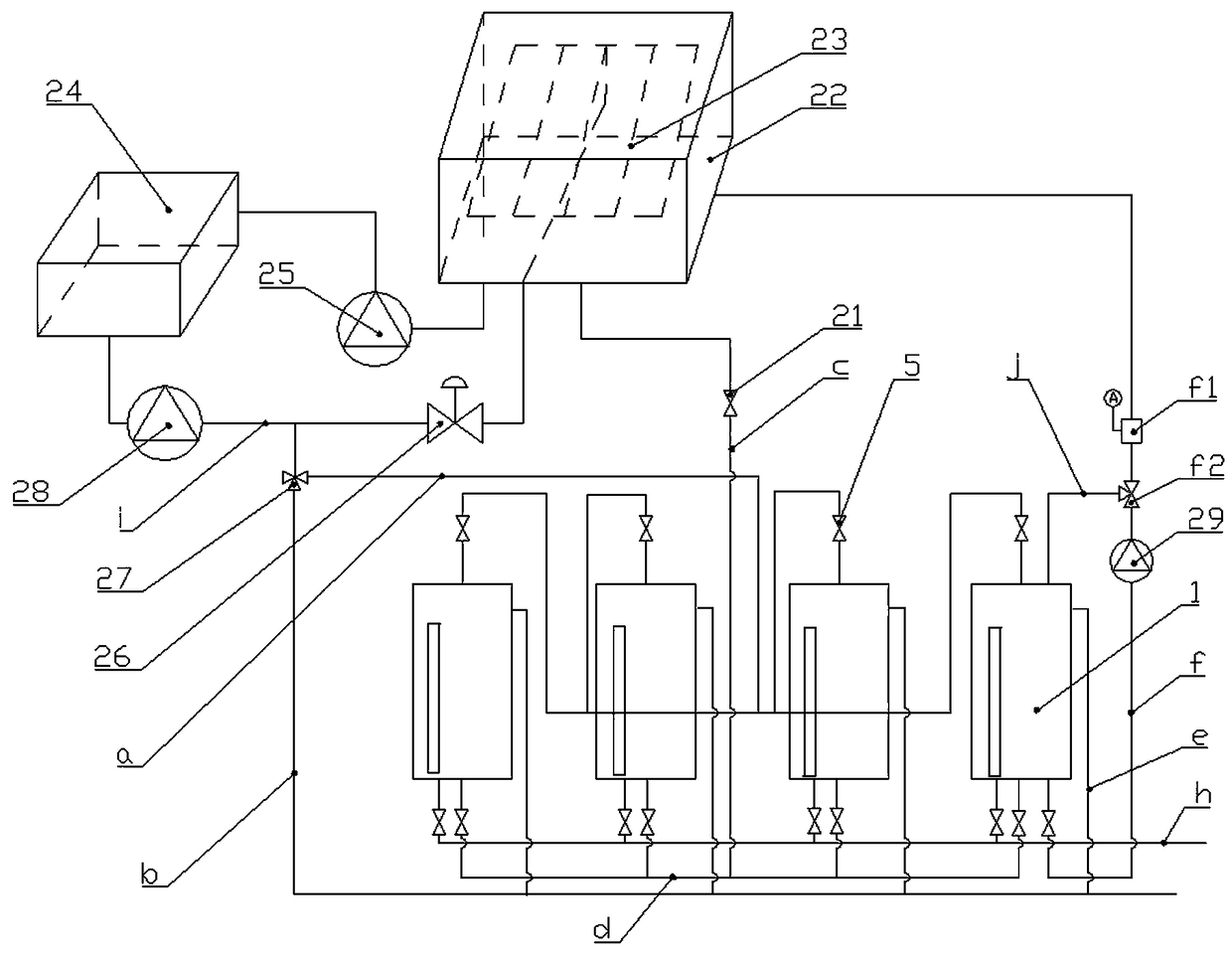

[0046] Embodiment one: material is carried out impregnating treatment, concrete process is as follows:

[0047] A, pour the lye that meets the concentration requirement in the mercerized dipping cylinder 22;

[0048]B, close manual three-way valve 27, mercerizing dipping cylinder 22, lye circulating pump A25, lye filtering device 24, lye circulating pump B28, spraying system connection pipeline i, lye spraying pipe 23 form a circulating pipeline;

[0049] C, the material is impregnated in the mercerizing impregnation cylinder 22;

[0050] D. Open the pneumatic valve 26 to make the lye spray the material.

Embodiment 2

[0051] Embodiment two: lye recovery, concrete flow process is as follows:

[0052] In this embodiment, four tank bodies 1 are provided, which are respectively used for temporarily storing lyes of four different concentrations.

[0053] E. Open the liquid inlet manual switch valve 5 corresponding to one of the tanks 1, close the other tanks 1, mercerized dipping cylinder 22, lye circulation pump A25, lye filter device 24, lye circulation pump B28, manual three-way valve 27. One of the alkali inlet pipe a and the tank body 1 forms a closed pipeline;

[0054] F. The lye circulation pump A25 and the lye circulation pump B28 work, and the filtered lye is pumped into the corresponding tank body 1.

[0055] The lye is first filtered and then recycled into the tank body 1 to reduce the useless consumption of the system and ensure the purity of the lye.

Embodiment 3

[0056] Embodiment three: lye reuse, concrete process is as follows:

[0057] In this embodiment, four tank bodies 1 are provided, which are respectively used for temporarily storing lyes of four different concentrations.

[0058] G, emptying the mercerizing dipping tank 22;

[0059] H, select one of tank body 1 that meets the concentration requirement; Open the manual valve 21 on the delivery pipe c; Realize reuse after concentration detection and fine-tuning; repeat steps A to D for material processing.

[0060] In this embodiment, there is a height difference between the tank body 1 and the mercerized dipping vat 22, so that the lye flows by its own weight. According to the actual working conditions, the lye can also be circulated by pumping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com