Compound berth-alongside device for elevated trestle

An elevated trestle and berthing technology, which is applied in the field of ships, can solve problems such as limited buffering efficiency, damage to the trestle box structure, and inability to berth ships, so as to improve safety and reliability, expand berthing space, and increase anti-collision effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

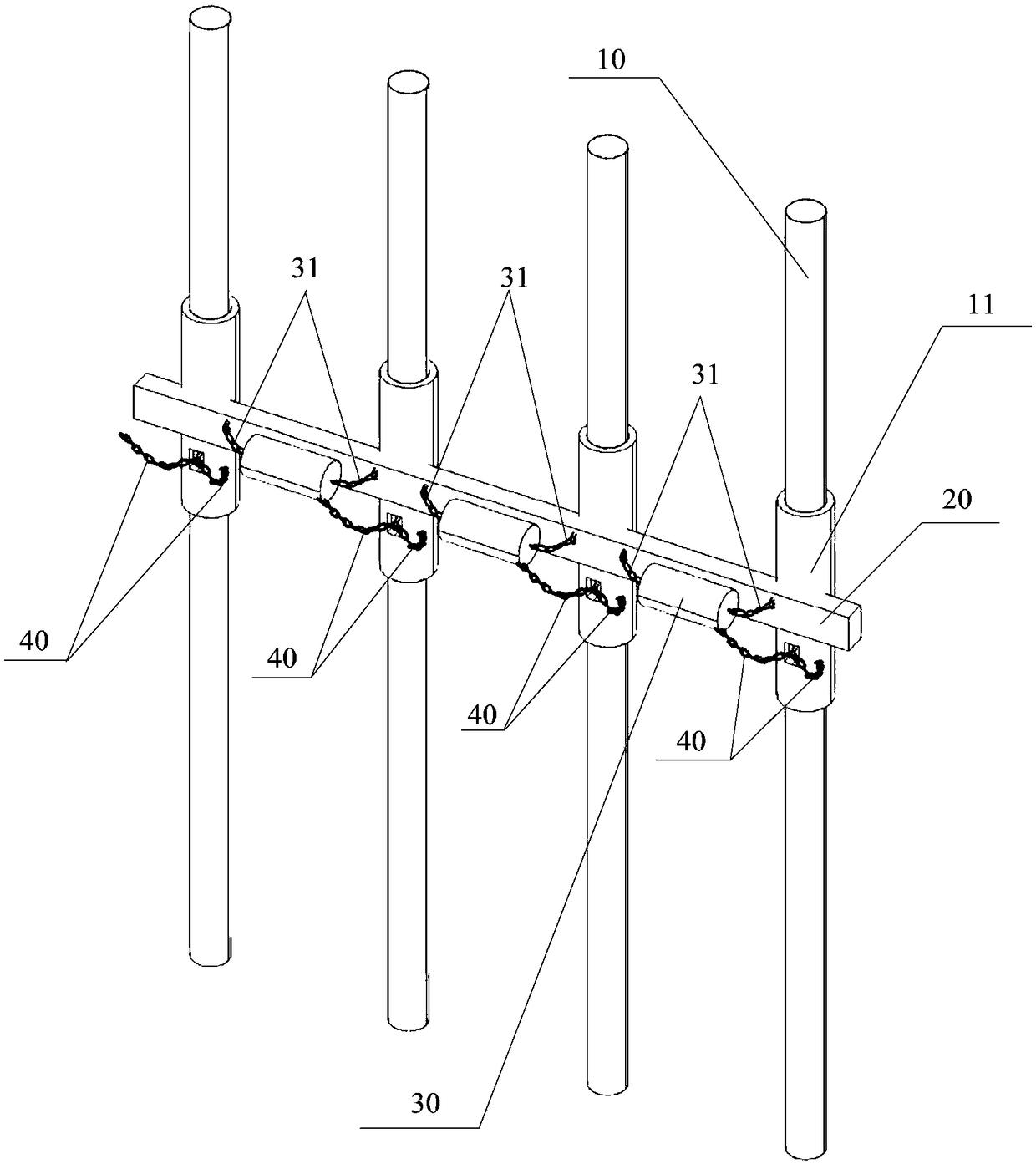

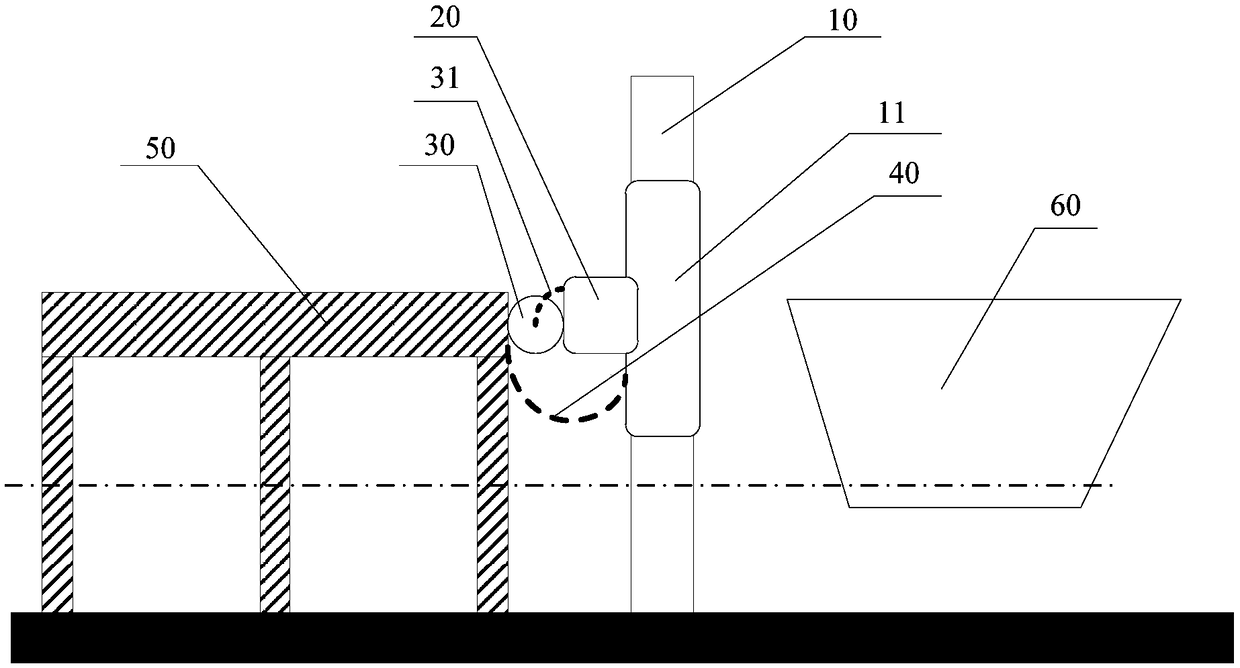

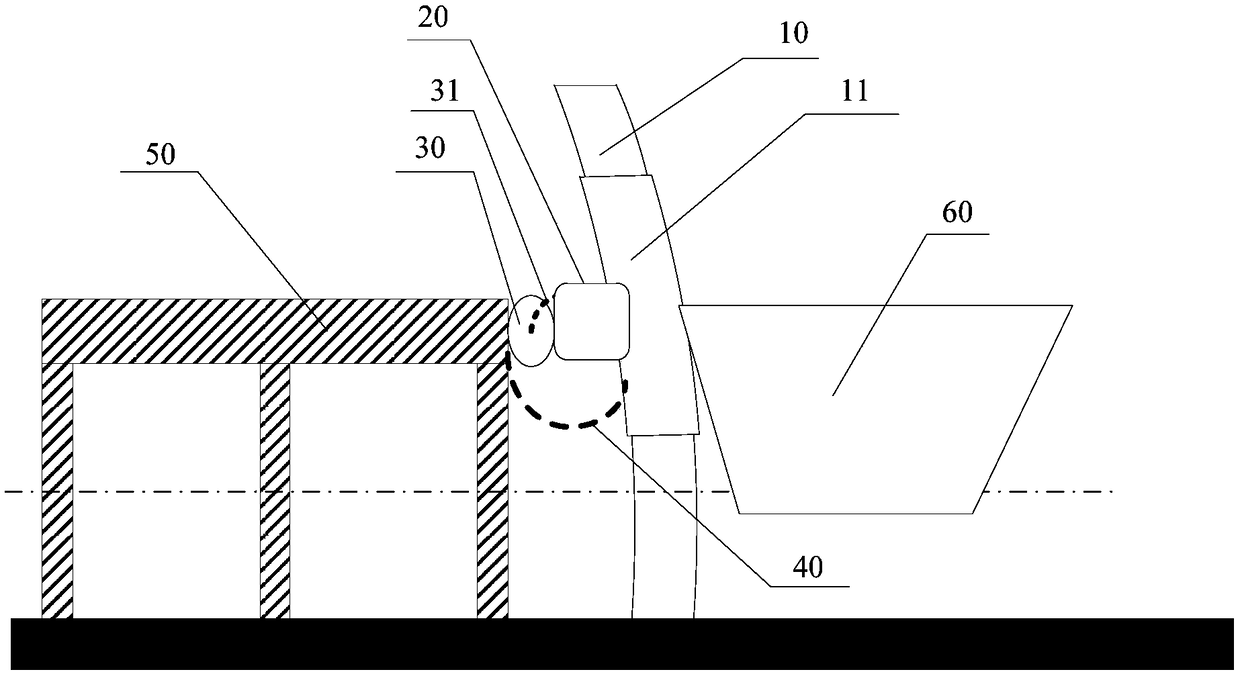

[0019] This application discloses a compound berthing device suitable for elevated trestles, please refer to figure 1 , the composite berthing device includes: N columns 10, beams 20 and several buffer pads 30, N≥2 and N is a positive integer, this application takes N=4 as an example, the specifications of N columns 10 are the same, N The uprights 10 are arranged in parallel. Normally, the distance between every two uprights 10 is equal. The distance between the uprights 10 is generally an empirical value, which is not limited in this application. The beam 20 vertically spans one side of the N columns 10 and is respectively connected with the N columns 10 to form a bent structure. The height of the entire bent structure is the height of each column, and the width of the entire bent structure is N The width formed by the uniform distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com