Large scale projection type printing-down apparatus

A printing machine and projection technology, applied in the field of printing machines, can solve the problems that the fine lines cannot be fully developed, the film cannot be closely attached to the screen, and the effective exposure area is limited, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

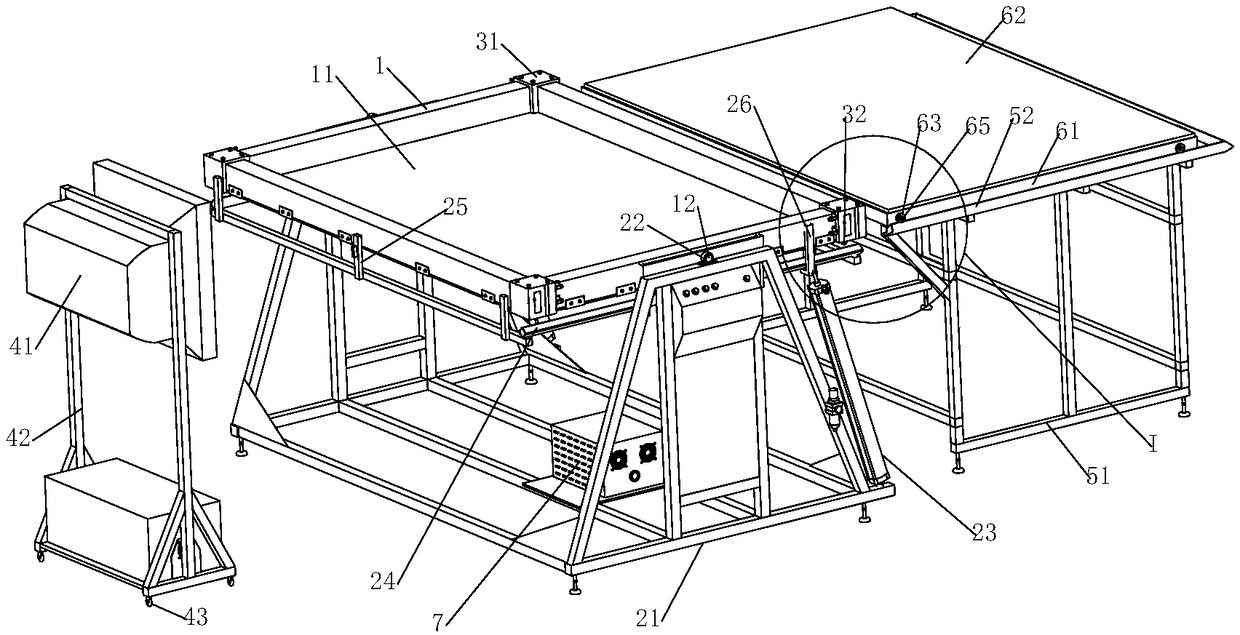

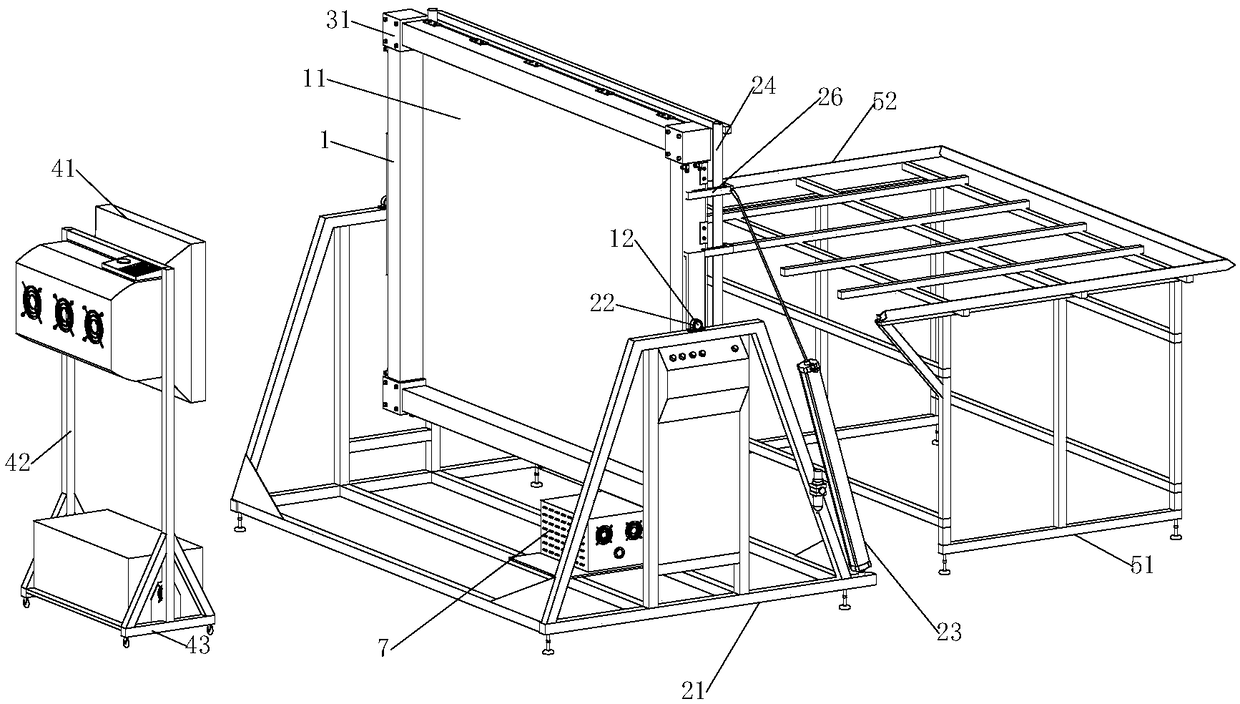

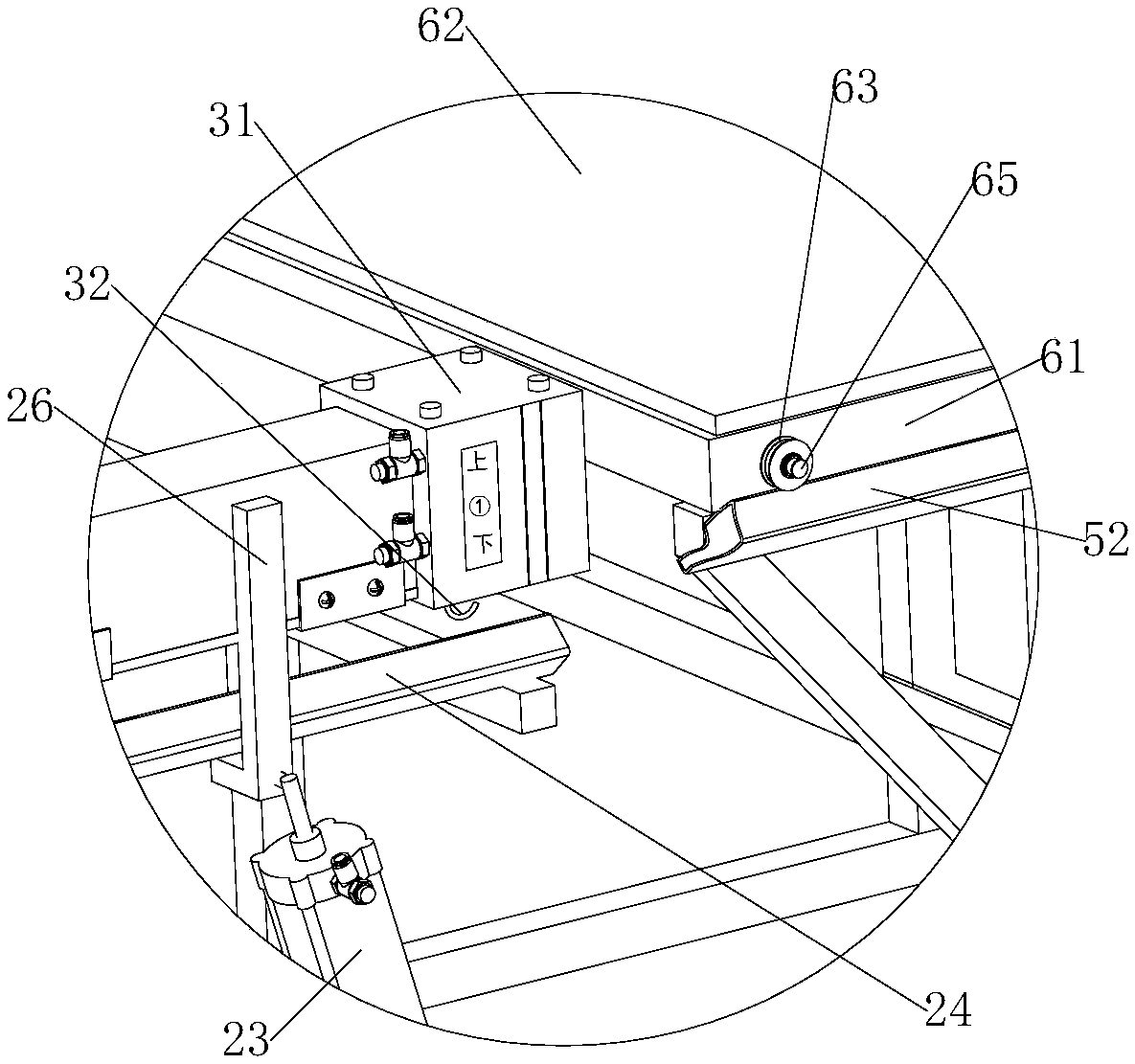

[0031] Such as figure 1 , figure 2 and image 3 As shown, a large-scale projection printing machine includes a lamp tube and a lampshade 41. The lamp tube is an ultraviolet lamp. The lamp tube is installed in the lampshade 41. The lampshade 41 is fixed on the light source frame 42. Band brake roller 63. The light source frame 42 is located at one end of the turning device. The position of the light source frame 42 can be adjusted, and the exposure area can be adjusted by adjusting the distance between the light source frame 42 and the printing frame 1, so as to be suitable for screen plates of different areas. When the screen area is large, make the lampshade 41 far away from the plate printing frame 1, the irradiation area of the light source becomes larger, make the light source irradiation area consistent with the area of the screen plate, and prolong the irradiation time to realize printing. When the screen area is small, make the lampshade 41 close to the plate p...

Embodiment 2

[0044] On the basis of the above-mentioned embodiments, it also includes a plate-making frame 51, which is located at the other end of the turning device, and both sides of the top of the plate-making frame 51 are symmetrically provided with plate-making guide rails 52, and the plate-making guide rails 52 and the plate-making guide rails 24 are the same guide rails , and the plate making guide rail 52 and the plate printing guide rail 24 are all on the same axis.

[0045] The plate-making guide rail 52 and the plate-printing guide rail 24 are all square tubes, and the square tubes are placed horizontally, that is, the angle between any side of the square tube and the horizontal plane is 45 degrees.

[0046] The plate-making frame 51 is used to place the base plate 61, avoiding manual lifting of the base plate 61, reducing labor intensity, reducing potential safety hazards, preventing industrial accidents, and conveniently combining the coated PS plate and film simultaneously. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap