Centrifugal potting device for potting harness connector and working method of centrifugal potting device

A centrifugal, glue-filling technology, which is applied in the assembly/disassembly, connection, circuit/collector parts and other directions of contact parts, can solve problems such as inability to guarantee the quality of glue filling, affect the quality of glue filling, and insufficient filling, etc., to achieve The effect of saving quantity, improving the quality of glue pouring and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

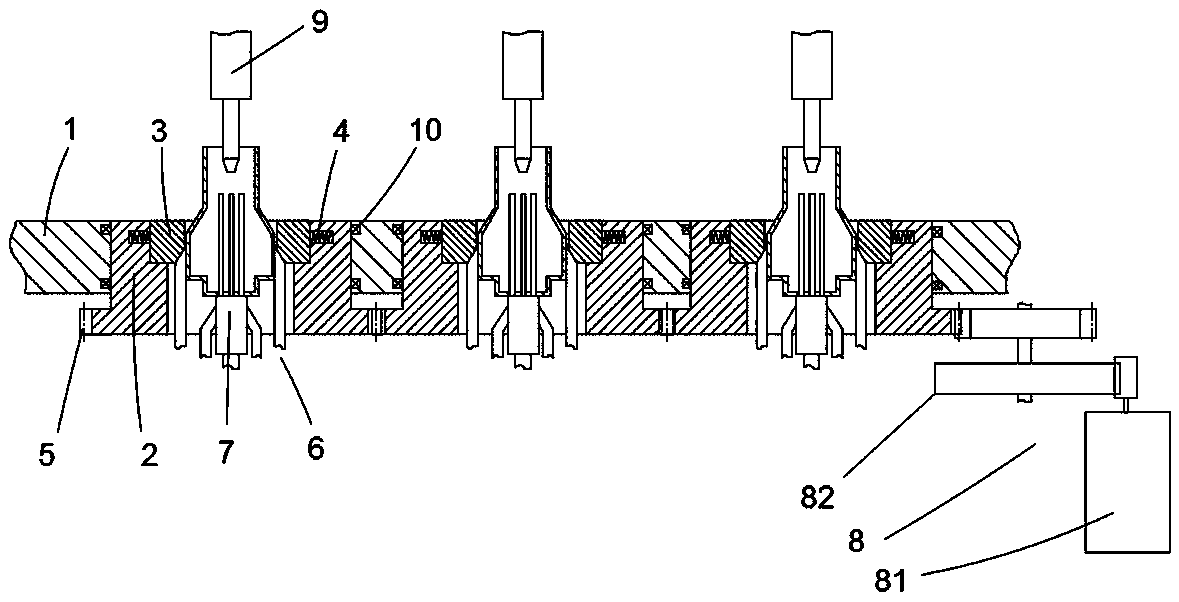

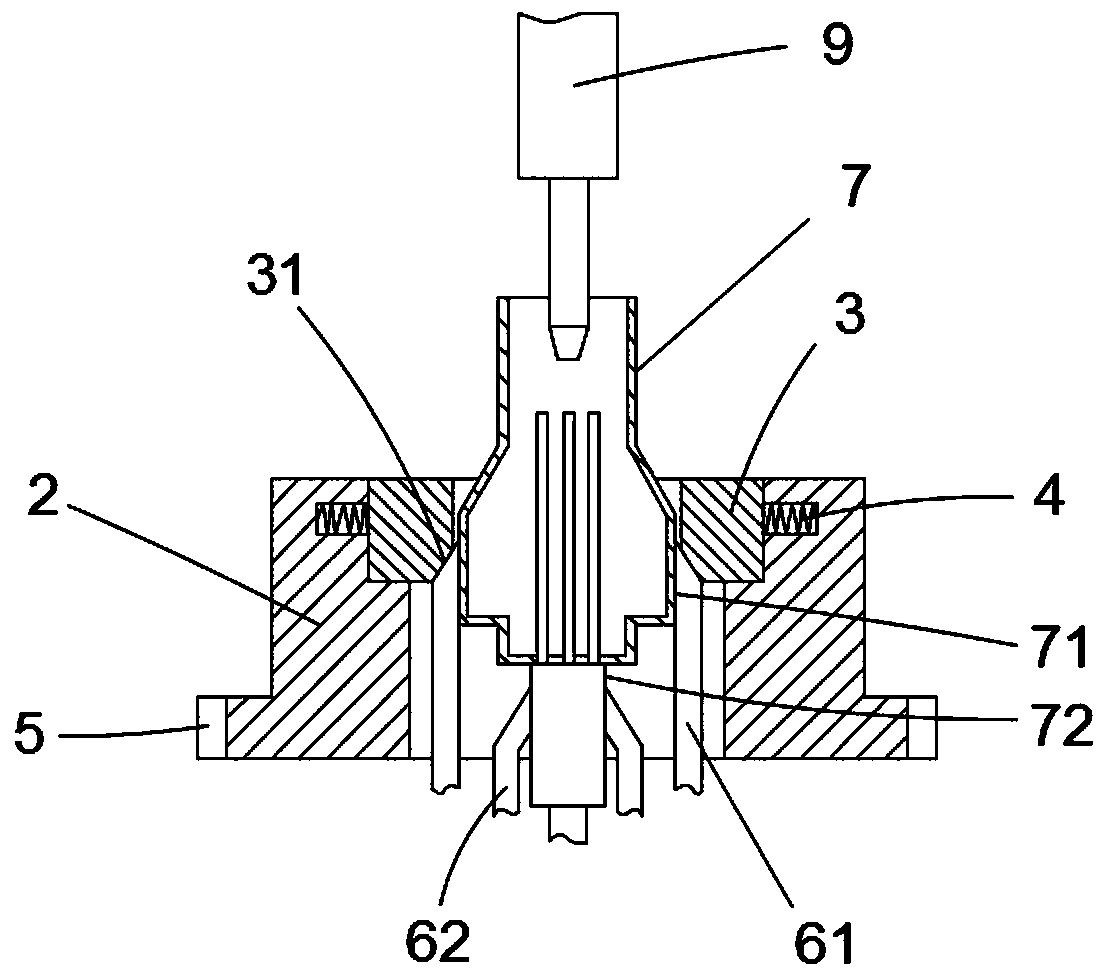

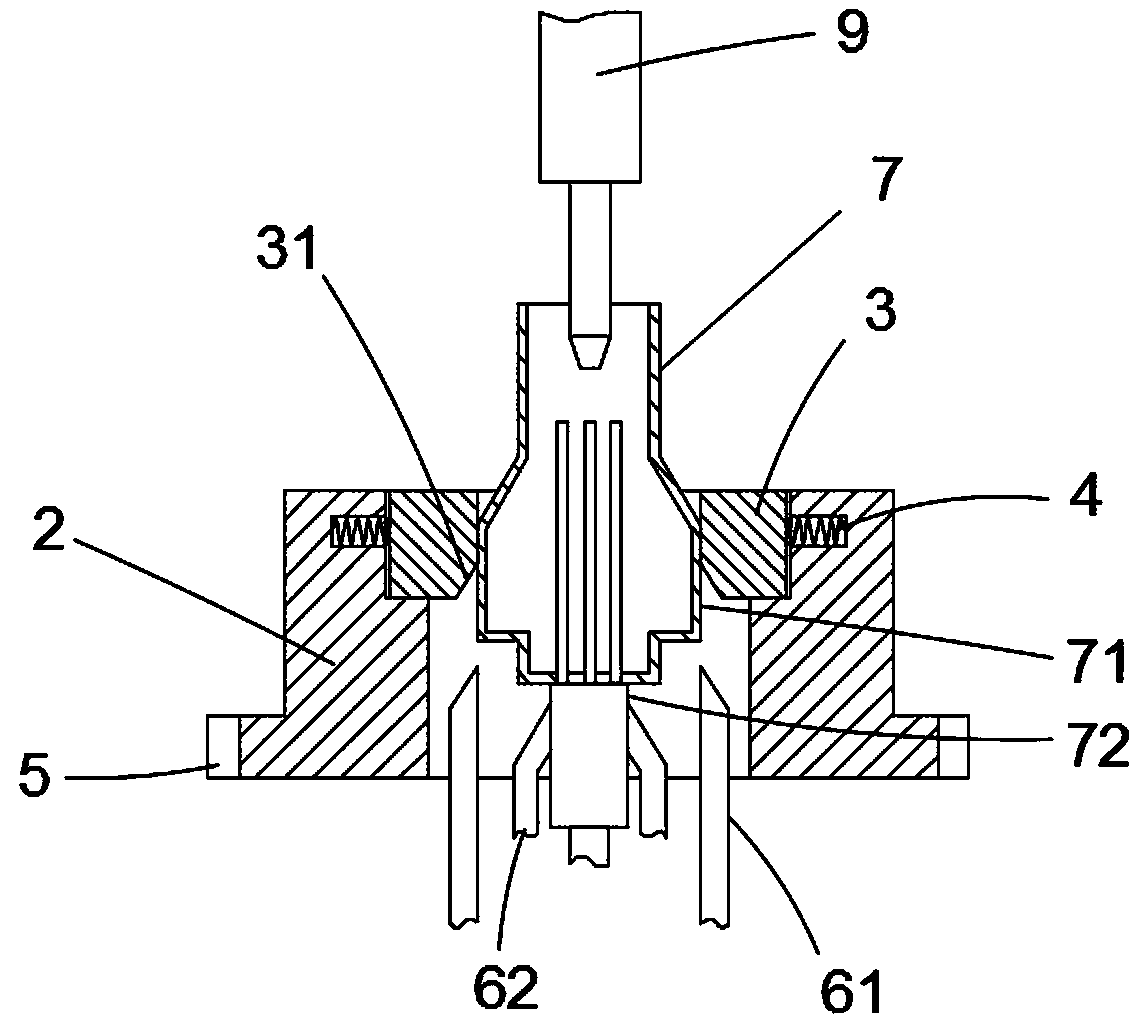

[0024] A kind of centrifugal glue-filling device for wire harness joint glue-filling of the present invention, such as Figure 1 to Figure 3 As shown, it includes a glue potting workbench 1 and a set of clamping devices arranged on the glue potting workbench 1. The clamping device includes a base 2 that is rotatably connected with the glue potting A set of clamping parts 3 in the cavity; a set of bearings 10 is arranged between the base 2 and the glue filling workbench 1, the clamping part 3 is arranged on the upper end of the base 2, and the clamping part 3 and the An elastic member 4 is arranged between the bases 2, and the elastic member 4 is a compression spring; the lower end of the base 2 is provided with an outwardly protruding transmission gear part 5, and the transmission gear part 5 of the adjacent clamping device Mesh with each other; a feeding and retrieving device 6 is provided below the clamping device. The feeding and retrieving device 6 includes a set of main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com