Energy-saving method and device for controlling belt conveyor based on conveying capacity

A belt conveyor and conveying capacity technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of energy waste, uneven distribution of transported goods, small transportation volume, etc., to avoid energy waste, The effect of reducing the capture time of broken belt, simple structure, stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

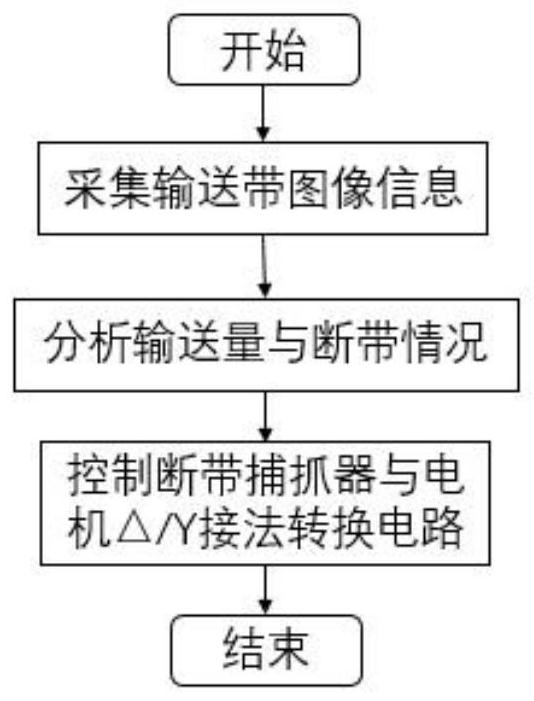

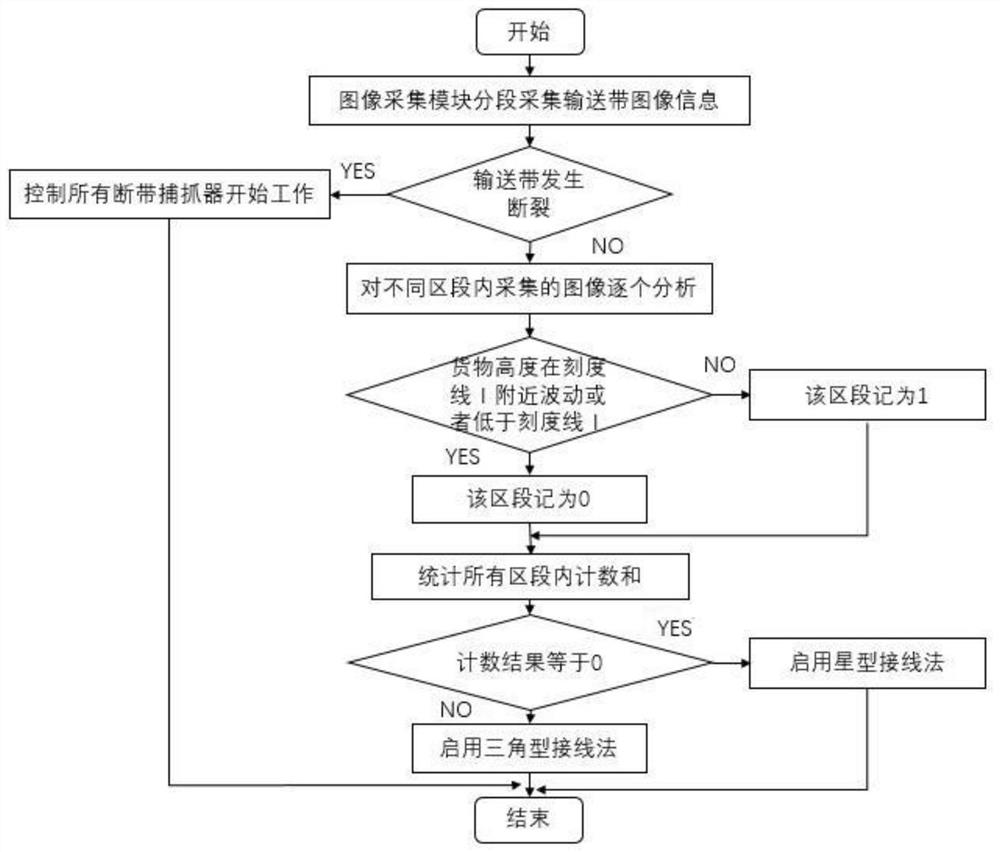

[0032] like figure 1 and 2 As shown, an energy-saving method for controlling belt conveyors based on conveying volume involved in this embodiment includes:

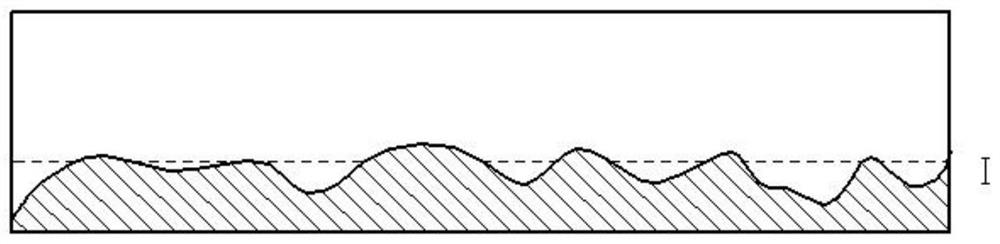

[0033] A. Installation: On one side of the belt conveyor 1, set the conveying volume reference plate 4 continuously along the direction of the belt conveyor 1, and uniformly distribute image acquisition on the other side of the belt conveyor 1 along the direction of the belt conveyor 1 module, and the image acquisition direction of the image acquisition module is towards the delivery reference plate 4;

[0034] B. Acquisition of conveyor belt image information: the image acquisition module monitors the transport status of the belt conveyor 1 in real time with the transport volume reference plate 4 as the background, and transmits the acquired image information to the control system;

[0035] C. Analysis of conveying volume and broken belts: monitor the structural integrity of the belt conveyor 1 conveyor belt in real ti...

Embodiment 2

[0040] like Figure 5 and Image 6 As shown, this embodiment relates to a device for realizing the energy-saving method for controlling belt conveyors based on the delivery volume, including a belt conveyor 1, a broken belt catcher 3, a delivery volume reference plate 4, and an image acquisition module 6. The delivery volume reference plate 4 is fixed on one side of the belt conveyor 1 and continues uninterrupted along the direction of the belt conveyor 1; the image acquisition module 6 is fixed on the top of the fixed rod 12, and the fixed rod 12 is fixed by bolts Be positioned at the other side of belt conveyor 1 on the horizontal plane; Image acquisition module 6 is evenly distributed along belt conveyor 1 conveyance direction and the image acquisition direction of image acquisition module 6 is towards delivery amount reference plate 4, and image acquisition module 6 is with conveying The volume reference board 4 is used as the background to monitor the transport status of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com