Optical cabin pressure relief device

A pressure relief device and optical technology, which is applied in the laser field, can solve the problems of low pressure resistance, thin and large volume of the optical bulkhead of the laser system, and low pressure resistance, and achieve a simple, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

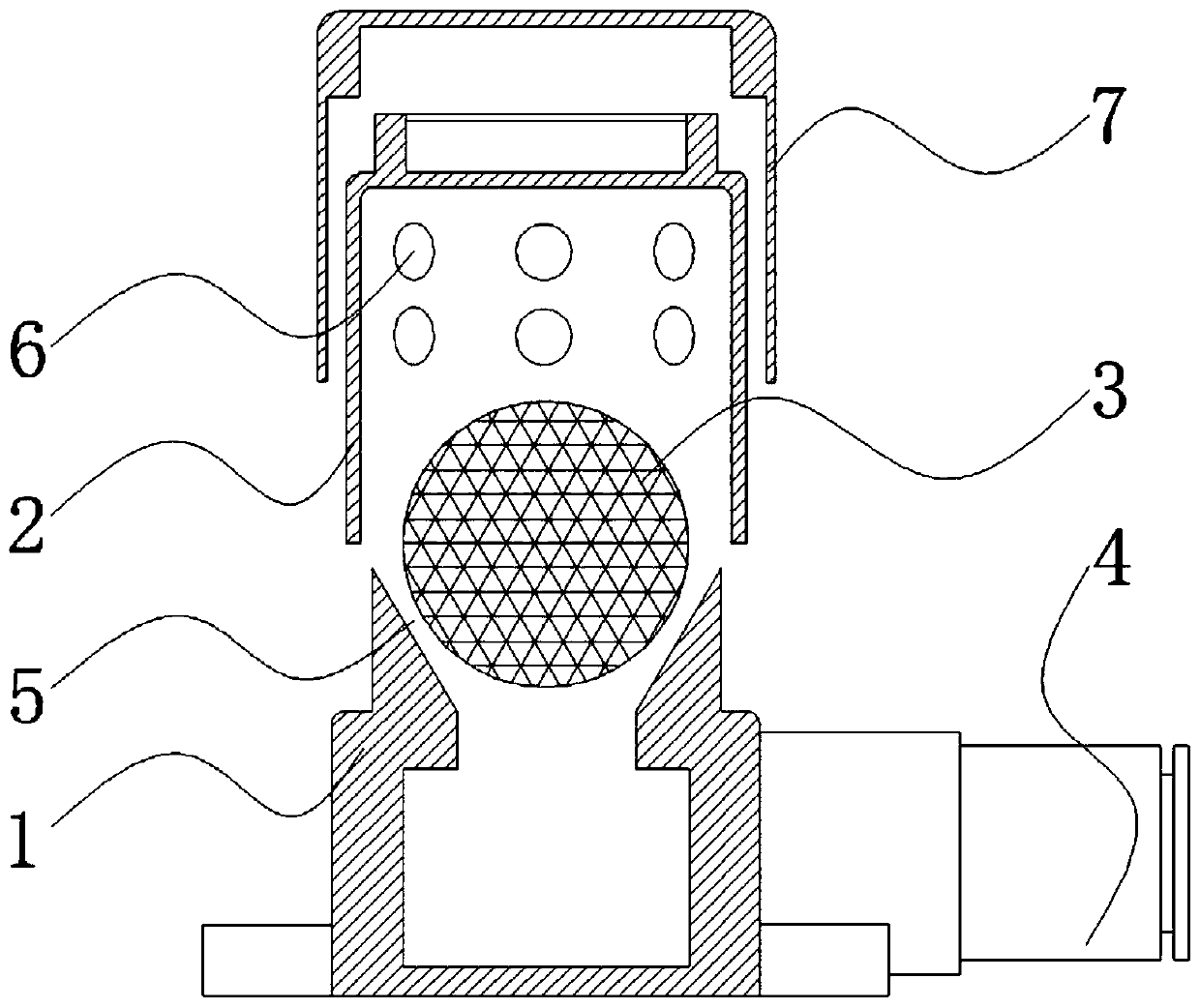

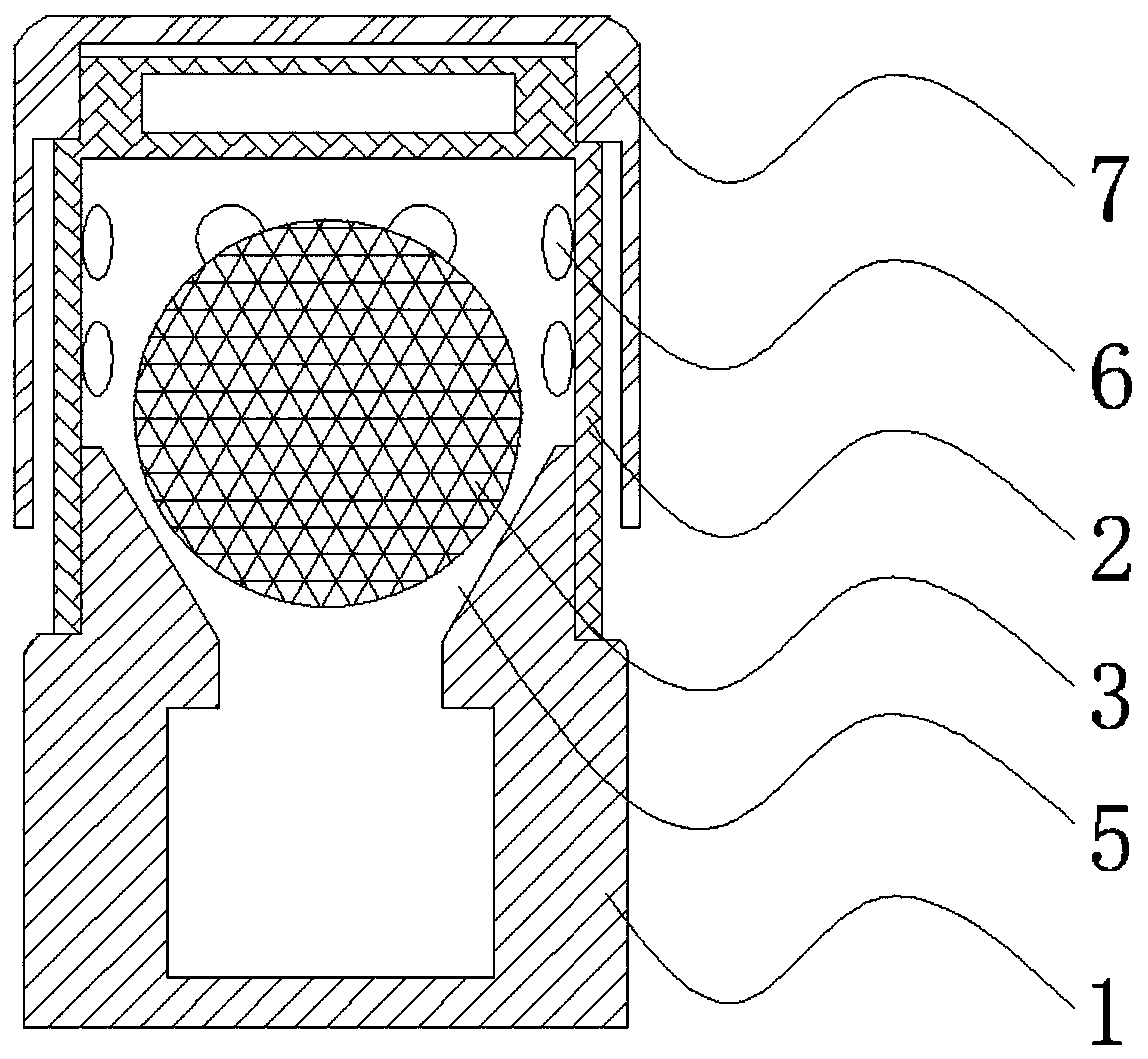

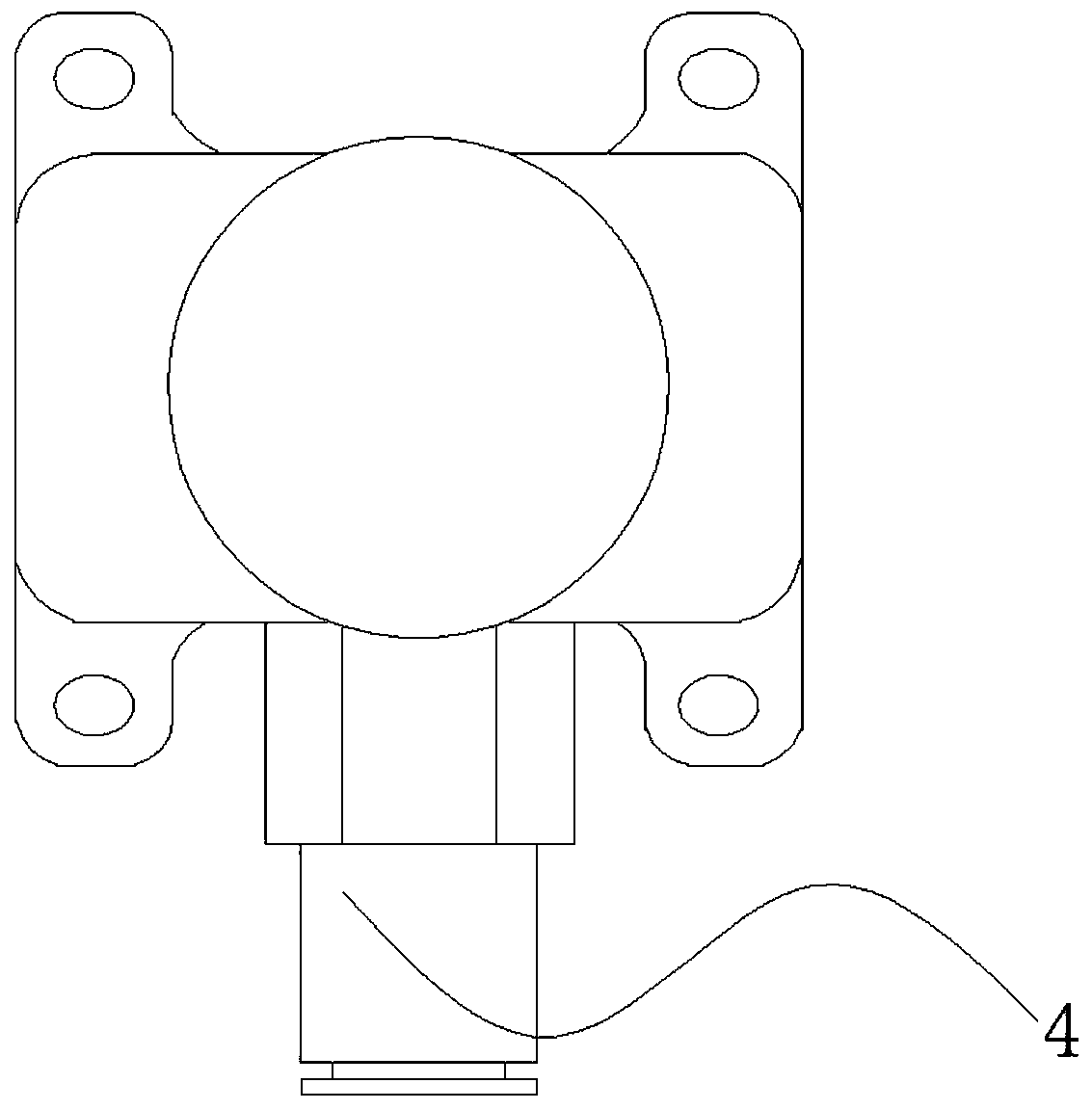

[0040] Such as Figure 2-3 As shown, an optical chamber pressure relief device of this embodiment includes an air cavity seat 1, an exhaust cover 2, a seal 3, an air nozzle joint 4 and a dust cover 7;

[0041] The top of the air cavity seat 1 is provided with an external thread column, and a tapered exhaust sealing port 5 is provided in the middle of the external thread column; the pressure-bearing floating ball is placed on the exhaust sealing port 5 and contacts with the exhaust sealing port 5 , forming a line seal on the contact surface, the seal 3 and the exhaust sealing port 5 are polished; the air cavity seat 1 is threaded with the air nozzle joint 4, the exhaust sealing port 5 communicates with the optical chamber through the air nozzle joint 4, and the air The nozzle joint 4 communicates with the optical cabin through the optical cabin exhaust hose;

[0042] The exhaust hood 2 is cylindrical, the top of the exhaust hood 2 is sealed, the bottom is open, and an exhaust ...

Embodiment 2

[0046] Such as Figure 2-3 As shown, an optical chamber pressure relief device of this embodiment includes an air cavity seat 1, an exhaust cover 2, a seal 3, an air nozzle joint 4 and a dust cover 7;

[0047] The top of the air cavity seat 1 is provided with two externally threaded columns, and the middle of the two externally threaded columns is provided with a tapered exhaust sealing port 5, and the two exhaust sealing ports 5 are connected through the cavity inside the air cavity seat 1; The pressure-bearing floating ball is placed on the exhaust sealing port 5, contacts with the exhaust sealing port 5, and forms a line seal on the contact surface, and the sealing member 3 and the exhaust sealing port 5 are all polished; The nozzle joint 4 is threaded, the exhaust sealing port 5 communicates with the optical cabin through the air nozzle joint 4, and the air nozzle joint 4 communicates with the optical cabin through the optical cabin exhaust hose;

[0048] The exhaust hood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com