Spraying machine

A technology for sprayers and generators, applied in horticulture, botany equipment and methods, devices for catching or killing insects, etc., can solve the problems of high cost of use, precipitation, and affecting the control effect, so as to improve the uniformity of pesticide application degree, reduce the cost of use, and reduce the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

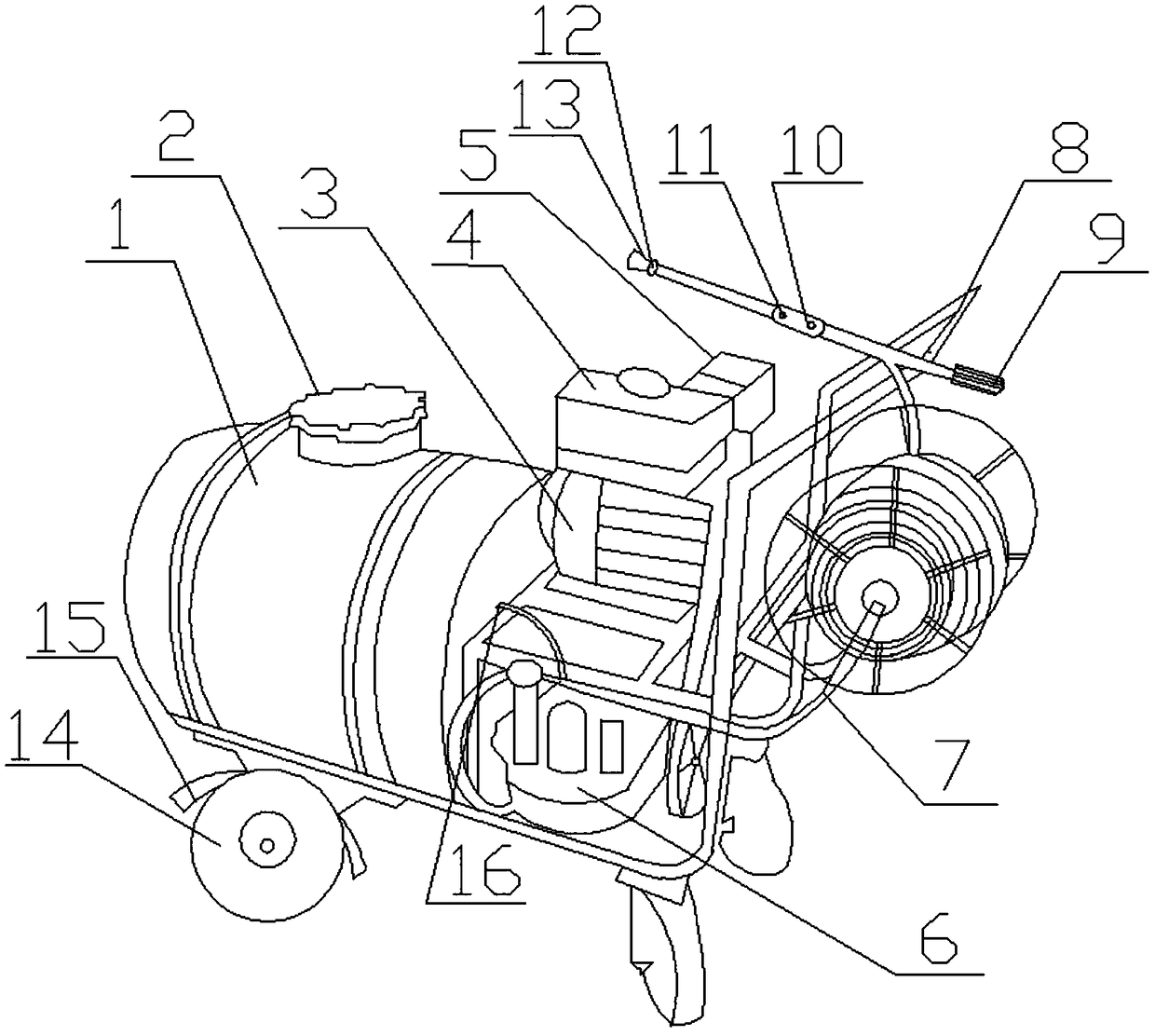

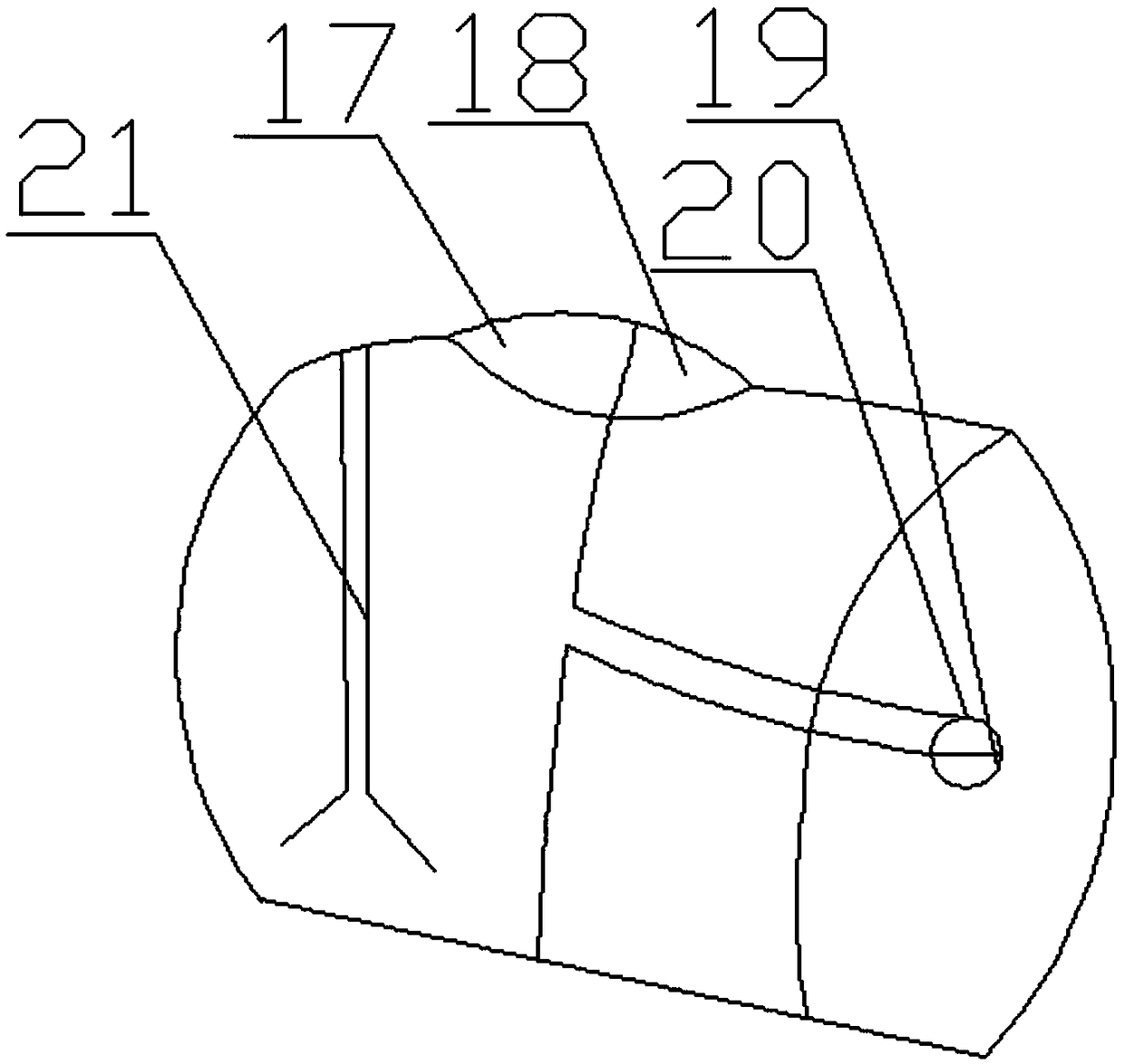

[0012] refer to figure 1 , figure 2 , a sprayer, its structure includes a box 1, a spray hose 7, a motor 3, a pressure pump 6, the box 1 is provided with a screw cover 2, the box 1 is located on the frame 8, so The vehicle frame 8 is provided with a generator 3, the generator 3 is provided with a medicine supply box 4, the generator 3 is connected with the storage battery pack 5, and the lower end of the generator 3 is provided with a pressure pump 6, and the generator 3 is provided with a pressure pump 6. The input end of the pressure pump 6 is connected with the box body 1, the output end of the pressure pump 6 is connected with the spray hose 7, and one end of the spray hose 7 is connected with the hand-held spray pipe 9, and the hand-held The spray pipe 9 is provided with a liquid medicine button 10, and the liquid medicine button 10 is connected with the water outlet button 11. The head of the hand-held spray pipe 9 is provided with a rotary port 12, and the rotary port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com