Banding strap automatic cutting machine

A cutting machine and automatic technology, which is applied to the parts and packaging of strapping machinery, so as to achieve the effect of high degree of automation and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

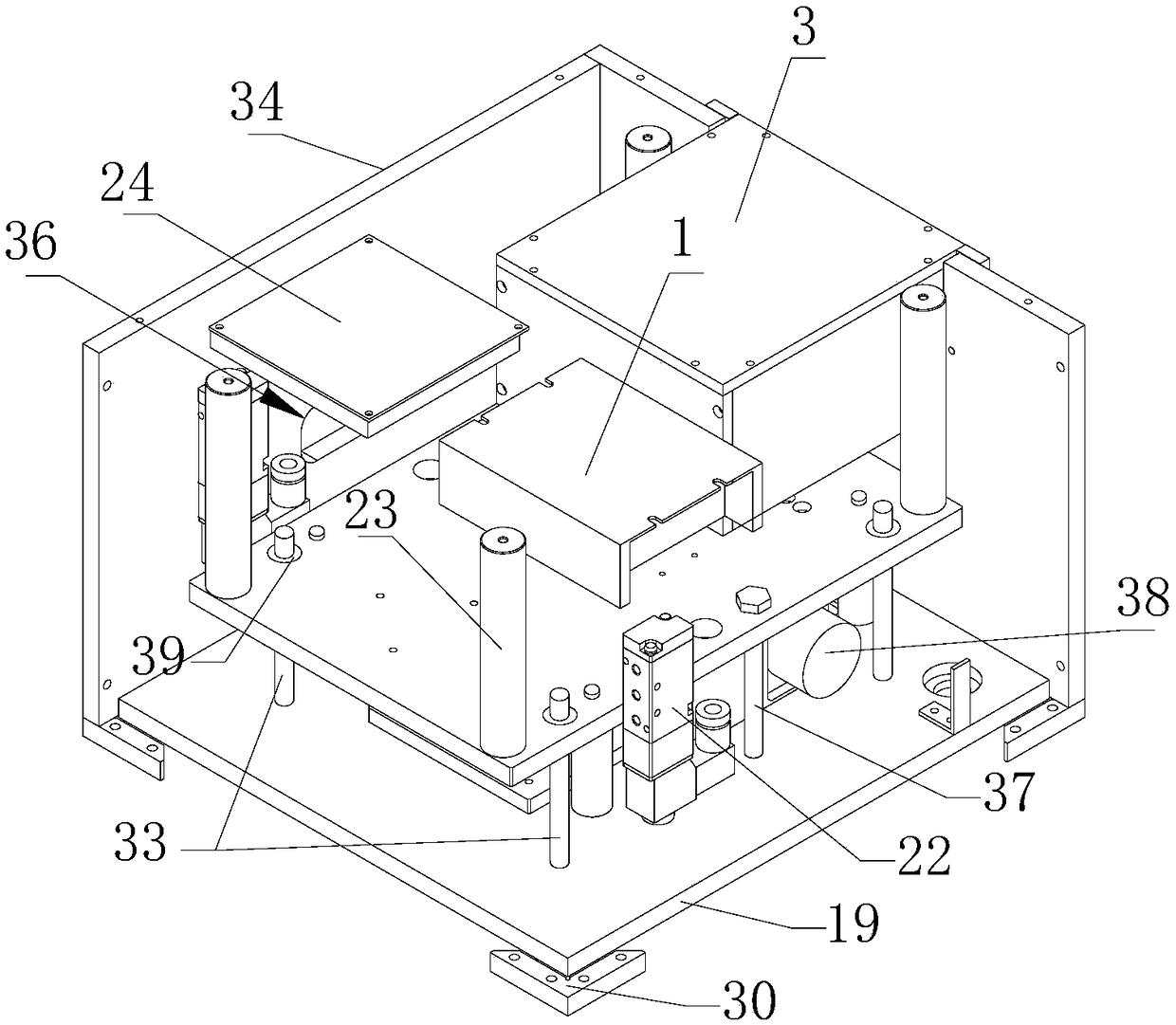

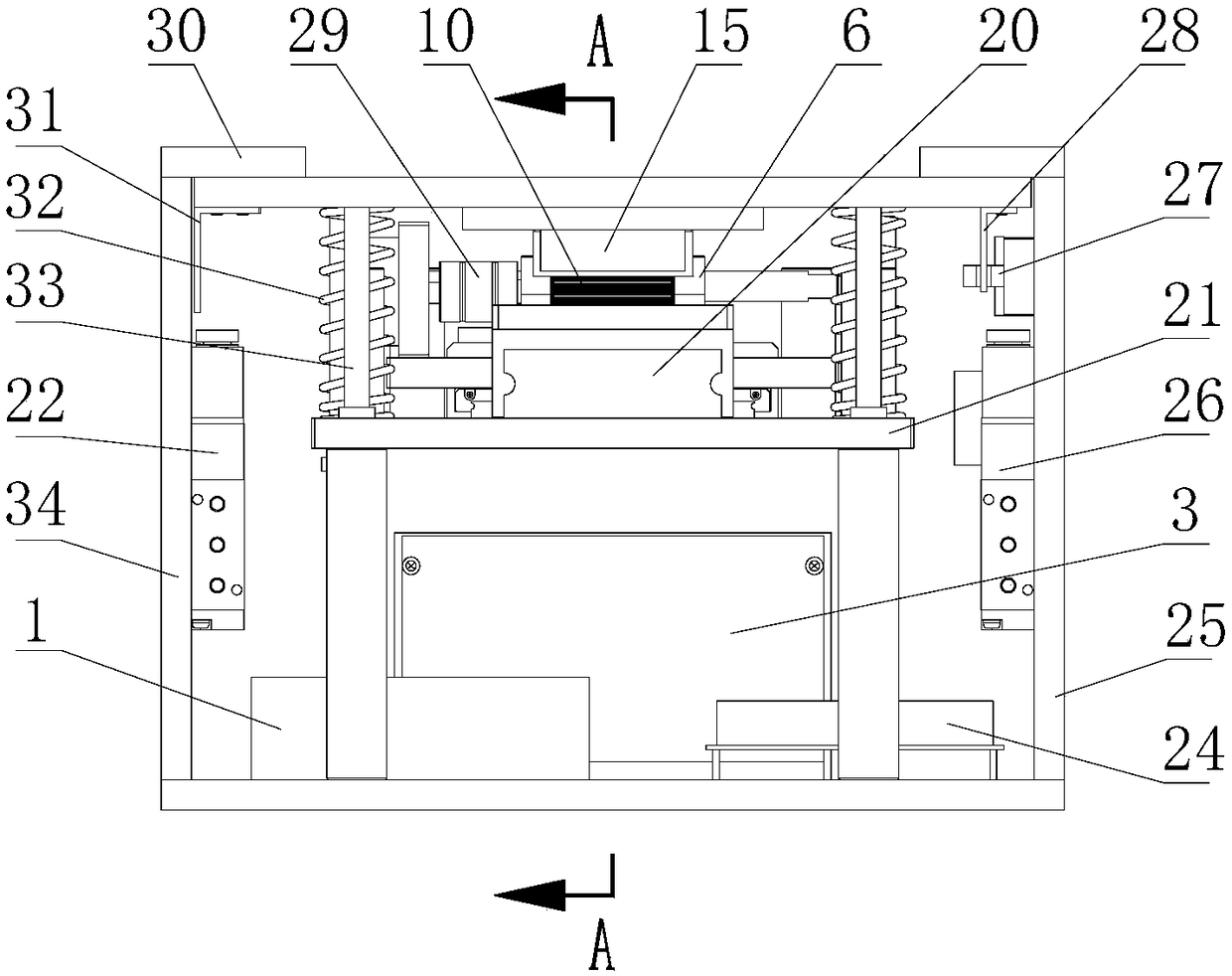

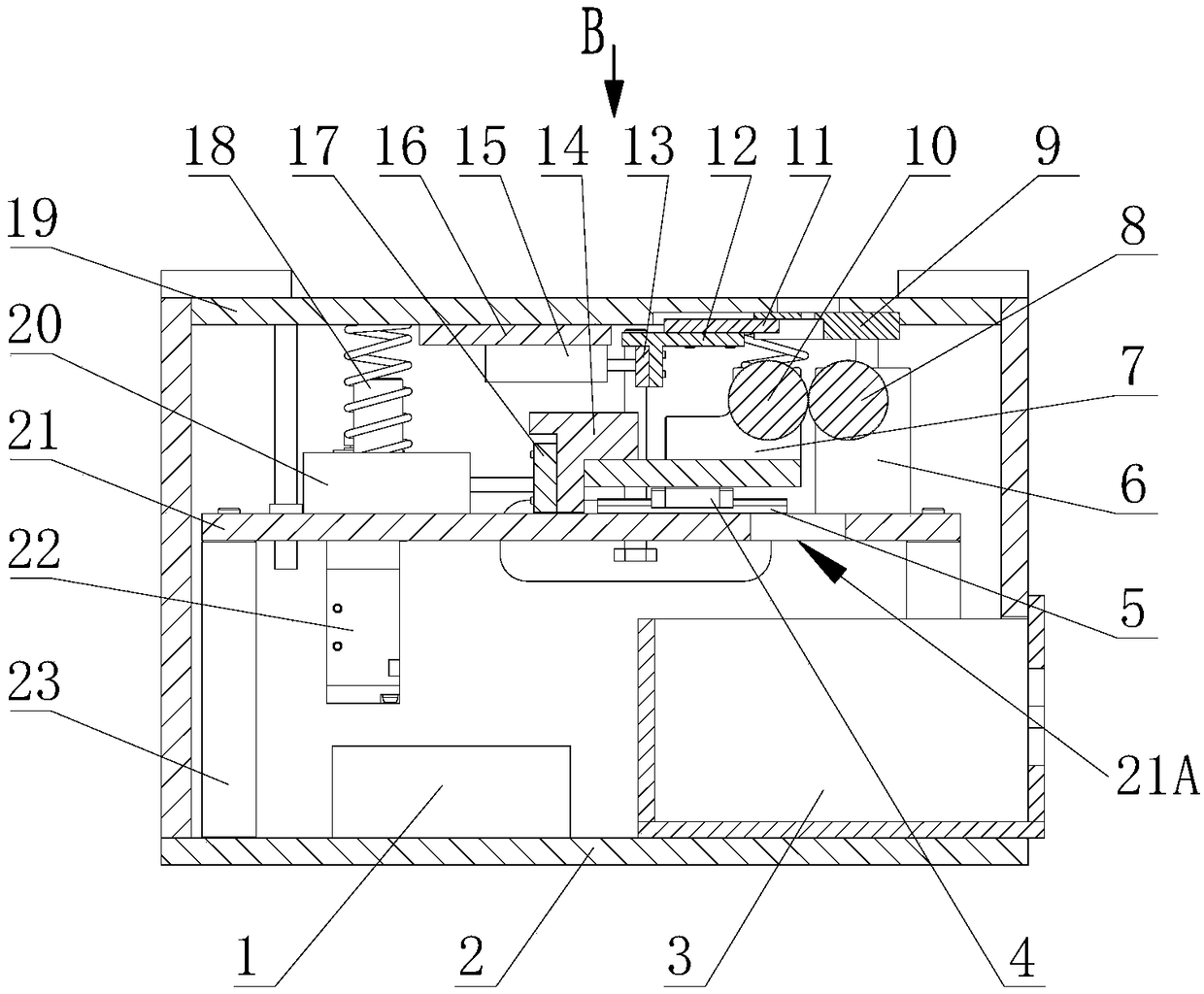

[0023] see figure 1 and Figure 4 , an automatic cutting machine for cable ties, comprising: a box body, a fixing plate, a tightening device, a shearing device and a control system.

[0024] The box body includes a bottom plate 2 and a cover plate 19 disposed opposite to the bottom plate 2. A first cable tie inlet 20A is defined on the cover plate 19, and a drawer box 3 for collecting waste is also arranged in the box body. , a power module 1 , which is installed on the base plate 2 to supply power to the device.

[0025] see figure 1 , figure 2 , image 3 and Figure 4 , the fixing plate 21 is arranged between the bottom plate 2 and the cover plate 19, and is installed on the four connecting rods 23 extending upward from the bottom plate 2, and the drawer box 3 is arranged on the bottom plate 2 and the Between the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com