Wipeable inkjet dye

A dye and inkjet technology, applied in the field of inkjet dyes, can solve the problems of large difference in fiber affinity, time-consuming and labor-consuming, large difference in hydrophilicity and lipophilicity, etc., and achieve the effect of good wipeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments.

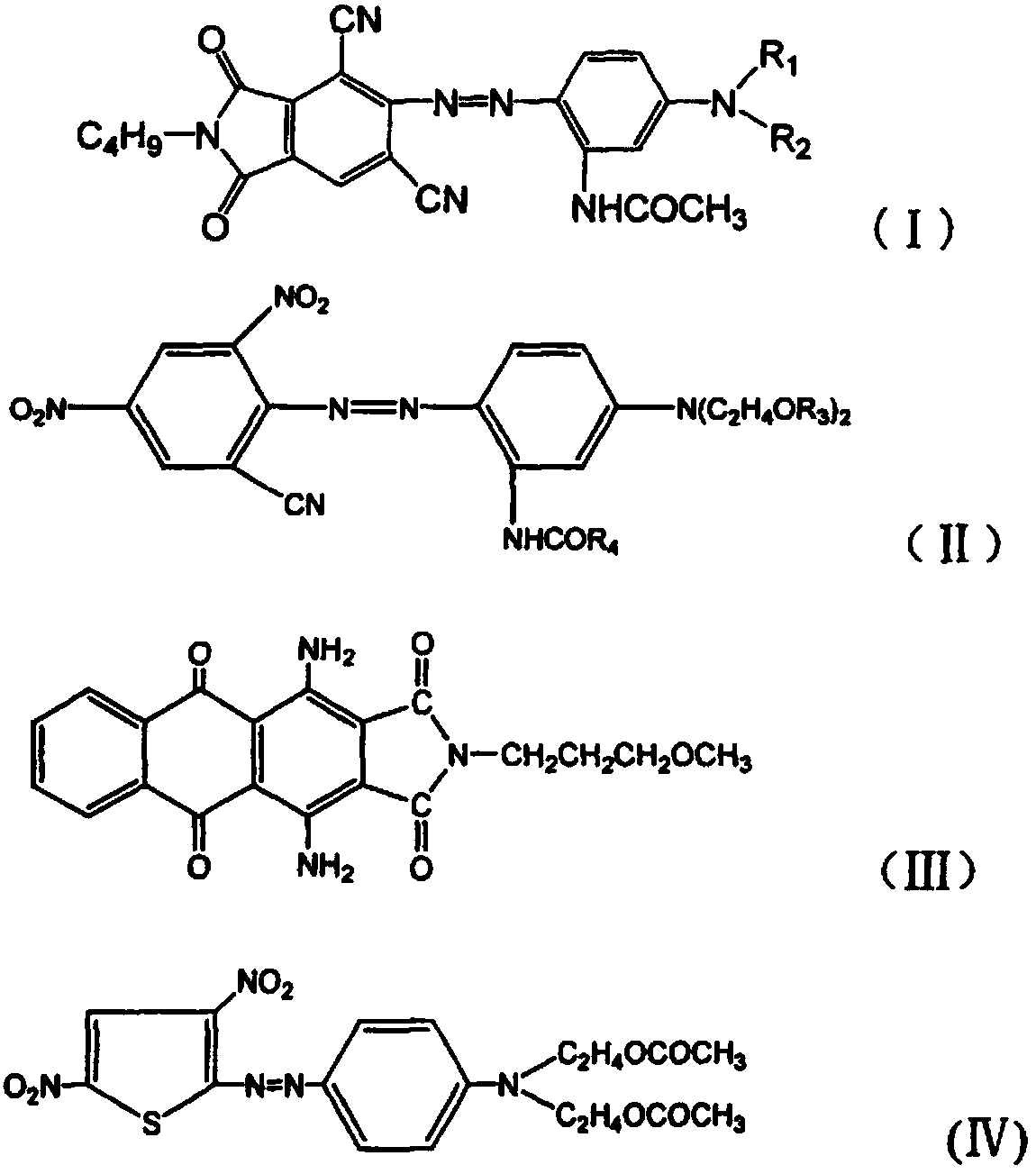

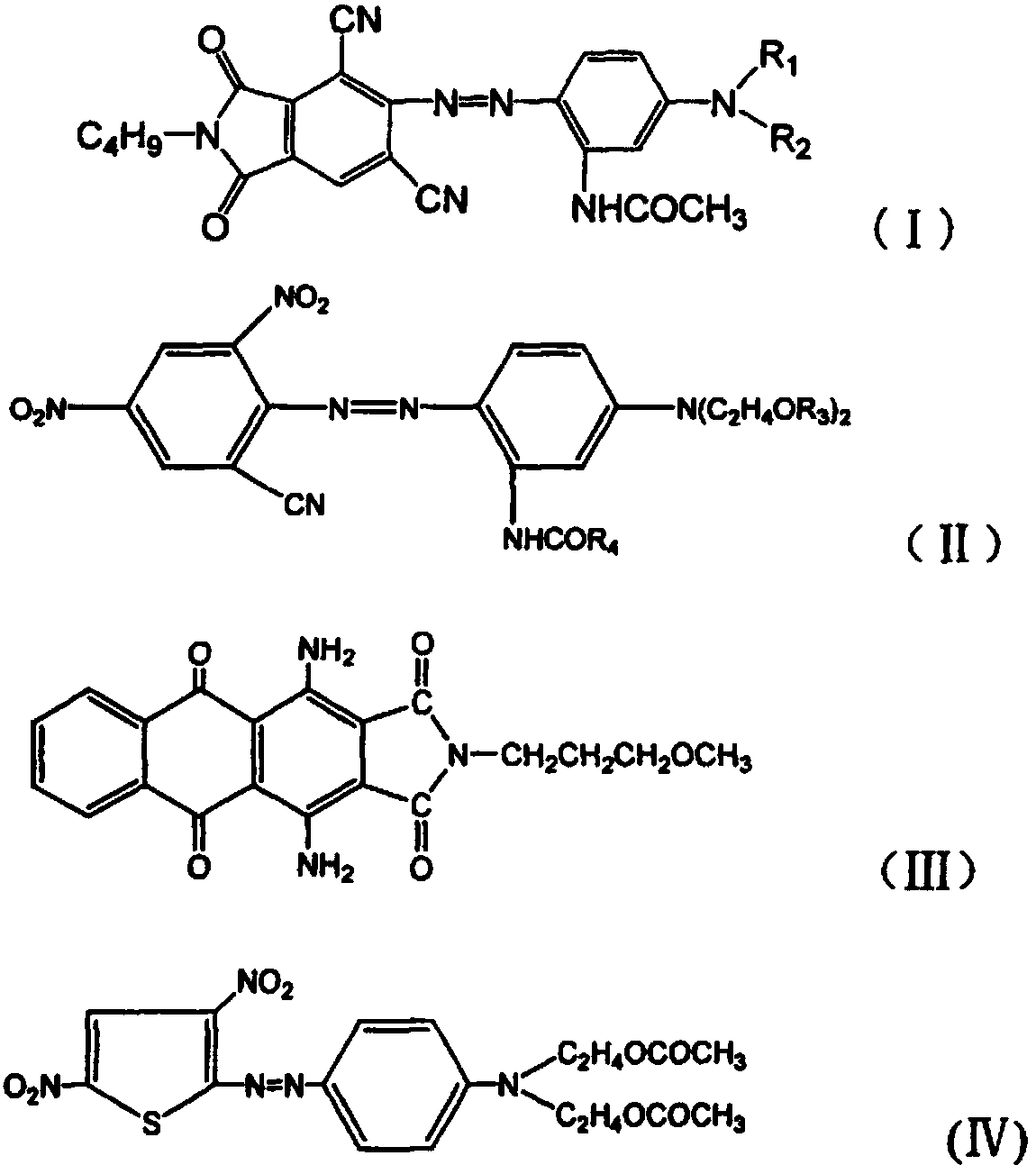

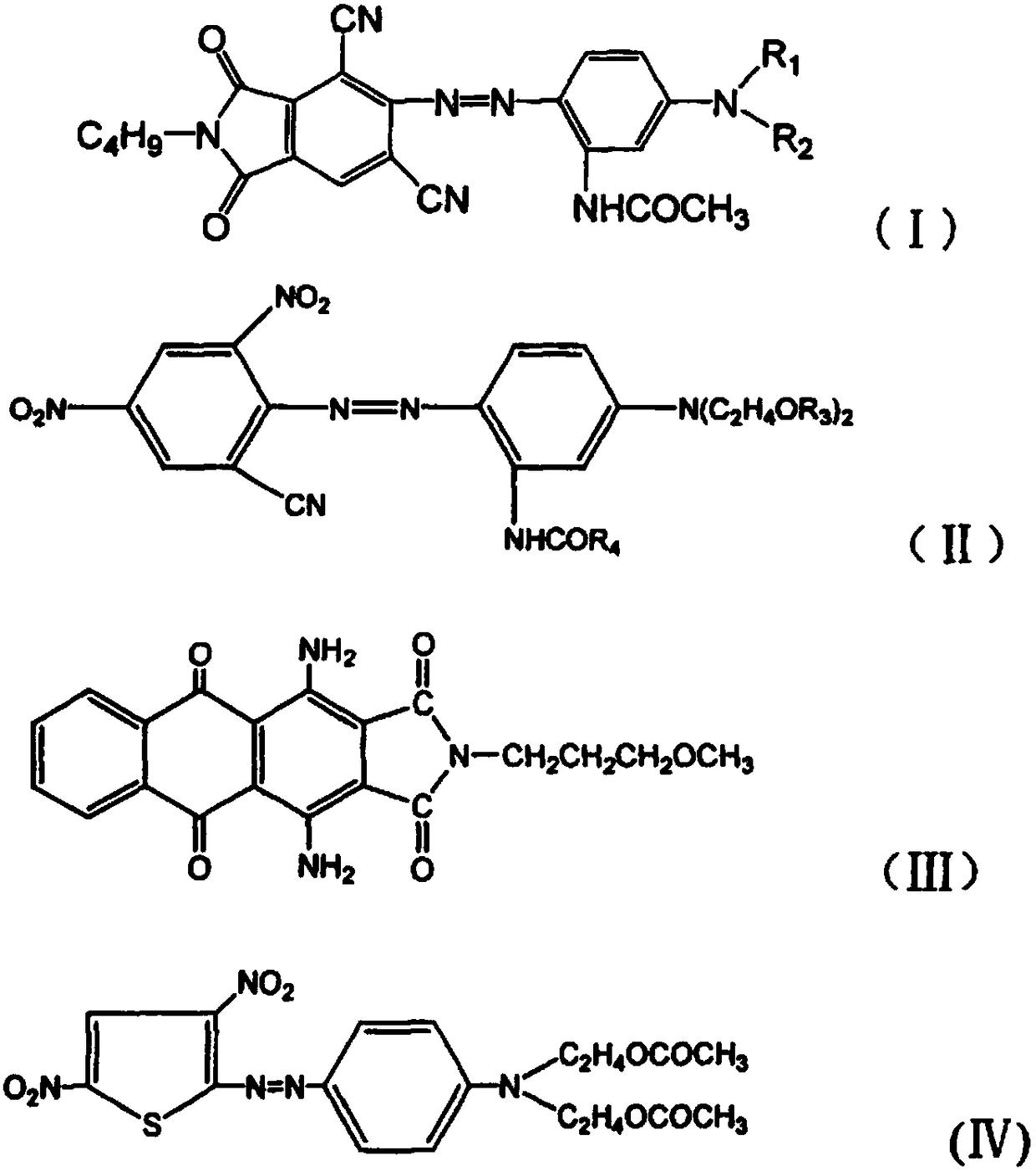

[0015] A wipeable inkjet dye involved in the present invention includes dye A shown in formula (I), dye B shown in formula (II), dye C shown in formula (III) and dye C shown in formula (IV) ) dye D;

[0016]

[0017] Wherein, R1, R2 are independently ethyl or methoxyethyl; R3, R4 are independently C1~

[0018] C4 alkyl.

[0019] Preferably, said R3 and R4 are each independently methyl or ethyl.

[0020] Preferably, it is basically composed of dye A, dye B, dye C, and dye D, and each of R1 and R2 is an ethyl group, and each of R3 and R4 is a methyl group.

[0021] As preferably, the weight percentage of dye A is 1-90%, the weight percentage of dye B is 1-50%, the weight percentage of dye C is 1-60%, and the weight percentage of dye D is 1-80%.

[0022] Compared with the prior art, the invention has the following beneficial effects: it has good wiping abilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com