Wipeable colored plastic crayon material and application thereof

A technology of colored plastics and crayons, which is applied in the field of lead materials, can solve the problems of erasable properties, crayons’ breaking resistance, coloring properties, etc., and achieve excellent coloring properties, excellent erasable properties, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

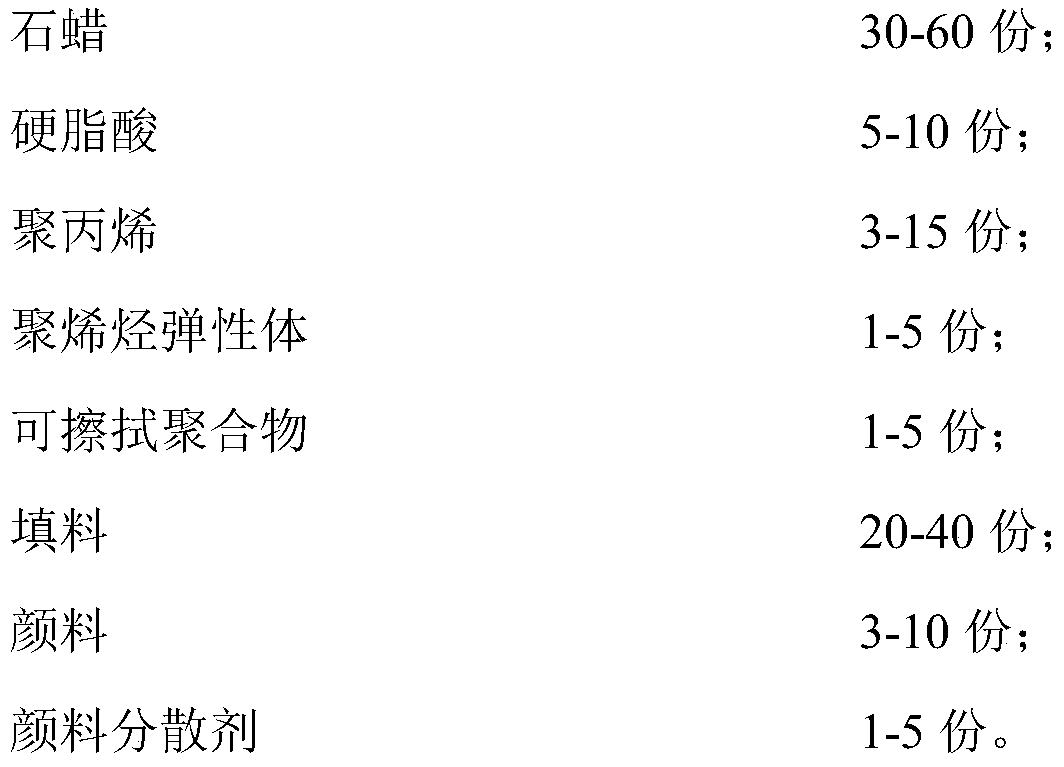

Method used

Image

Examples

Embodiment 1

[0022] A preparation of erasable colored plastic crayons:

[0023] Erasable color plastic crayon materials, including the following components in parts by weight: 30 parts of semi-refined paraffin, 8 parts of stearic acid, 7 parts of polypropylene, 2 parts of 4556 TPE, 1 part of SEBS, 20 parts of talcum powder, 20 parts of light calcium 5 parts of Yongguhuang, 5 parts of Wuhan hyperbranched HyperC100, 1 part of lubricant, and 1 part of fragrance.

[0024] The preparation method of the wipeable colored plastic crayon is as follows: add the above-mentioned raw materials into a reaction kettle and heat to 120°C, stir and melt for 5 hours to prepare the wipeable colored plastic crayon material; The crayon material is poured into a mold, then cooled and molded to obtain the erasable colored plastic crayons.

Embodiment 2

[0026] A preparation of erasable colored plastic crayons:

[0027] Wipeable colored plastic crayon materials, including the following components in parts by weight: 30 parts of fully refined paraffin wax, 15 parts of microcrystalline paraffin wax, 7 parts of stearic acid, 10 parts of polypropylene, 5 parts of 4556 TPE, and 2 parts of chlorinated polyethylene , 3 parts of SBS, 20 parts of kaolin, 3 parts of phthalocyanine blue, 2 parts of ethylene bis stearic acid amide, 1 part of German Wacker AK-1000, 1 part of thickener, 1 part of fragrance.

[0028] The preparation method of the wipeable colored plastic crayon is as follows: add the above-mentioned raw materials into a reaction kettle and heat to 150°C, stir and melt for 6 hours to prepare the wipeable colored plastic crayon material; The crayon material is poured into a mold, then cooled and molded to obtain the erasable colored plastic crayons.

Embodiment 3

[0030] A preparation of erasable colored plastic crayons:

[0031] Wipeable colored plastic crayon materials, including the following components in parts by weight: 25 parts of fully refined paraffin, 5 parts of microcrystalline paraffin, 5 parts of liquid paraffin, 5 parts of stearic acid, 13 parts of polypropylene, 2 parts of 4556 TPE, poly 5 parts of vinyl chloride, 20 parts of aluminum silicate, 10 parts of light calcium, 1 part of carbon black, 4 parts of titanium dioxide, 3 parts of pigment dispersant Clariant PE520, 1 part of lubricant, and 1 part of thickener.

[0032] The preparation method of the wipeable colored plastic crayon is as follows: add the above-mentioned raw materials into a reaction kettle and heat to 100°C, stir and melt for 4 hours to obtain the wipeable colored plastic crayon material; The crayon material is poured into a mold, then cooled and molded to obtain the erasable colored plastic crayons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com