Base structure for clothes embroider working table

A technology of workbench and embroidery table, which is applied in the field of sewing equipment and clothing workbench, can solve the problems of lack of humanization in design, easy to cause fatigue, and few workbench design considering the combination of multiple sets, so as to improve the level of humanization , relieve heat, save material and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

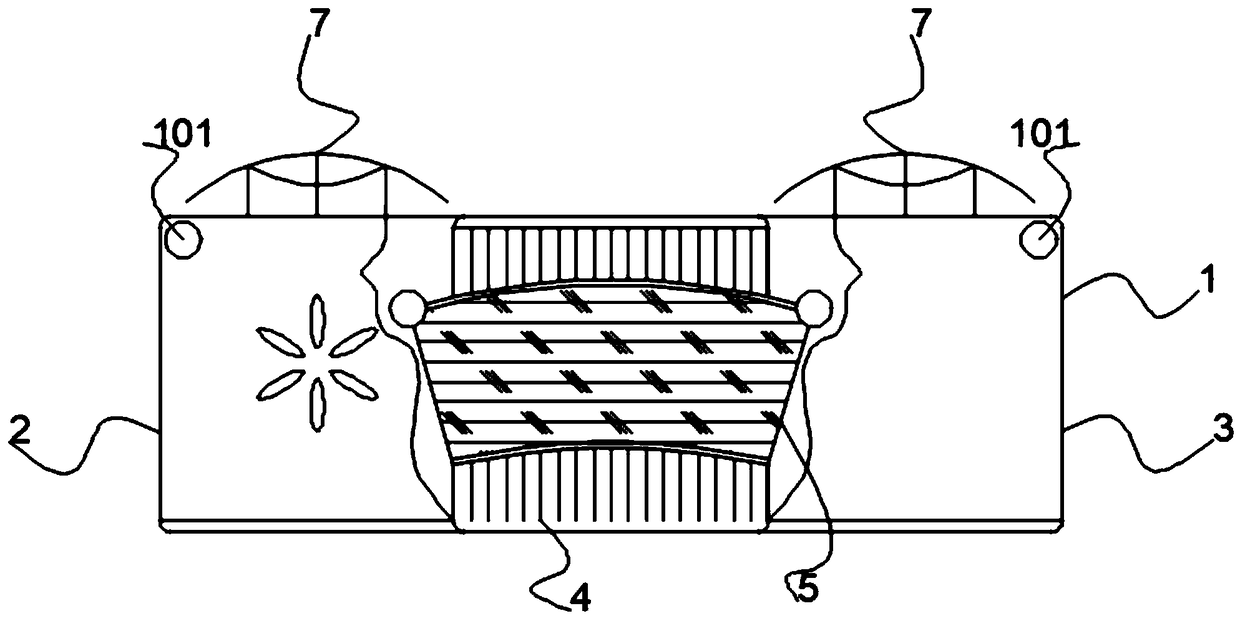

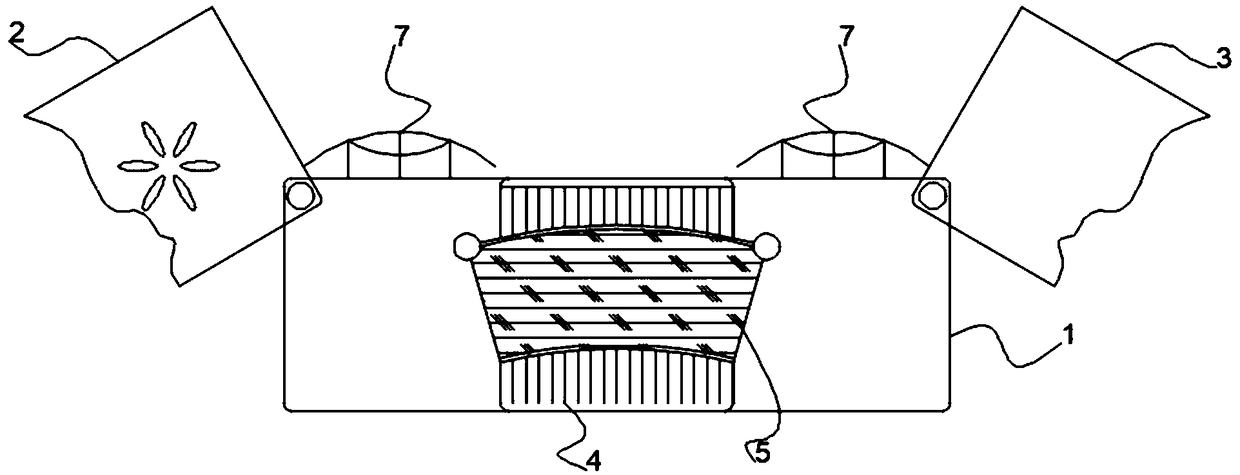

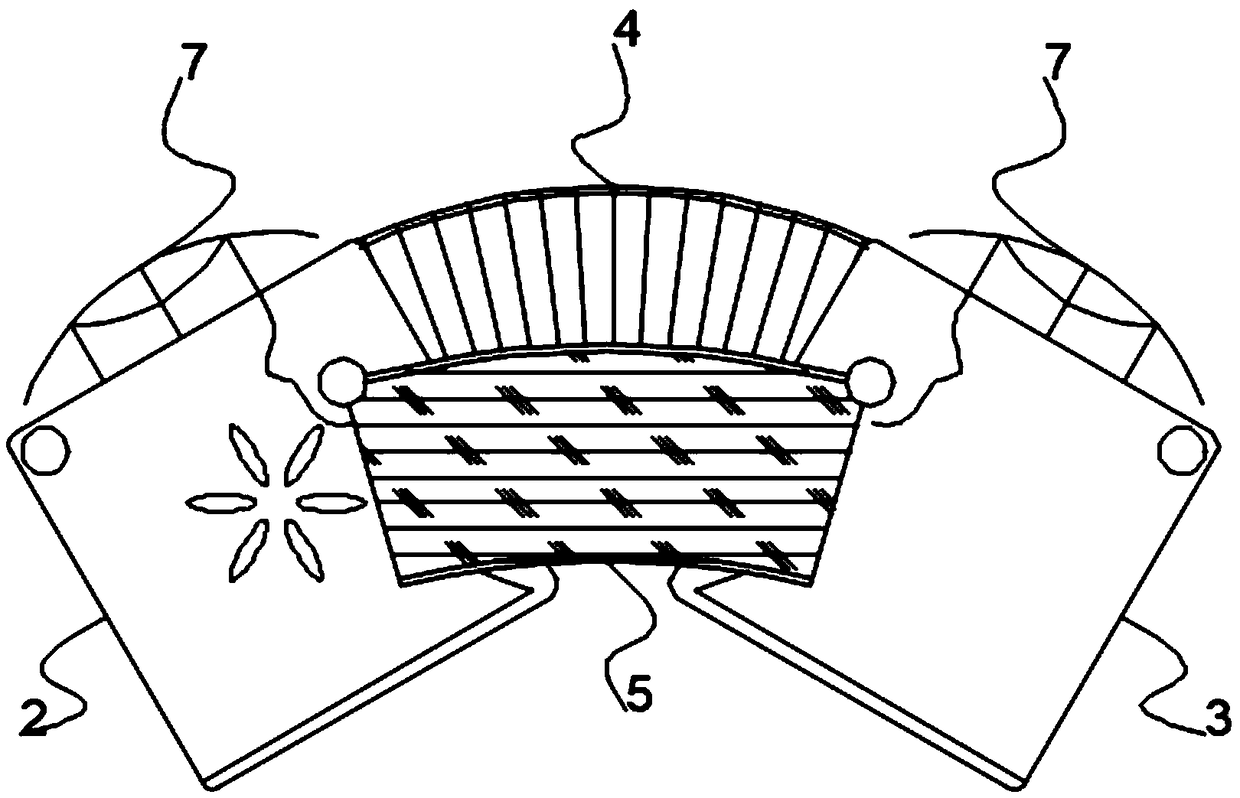

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The present invention provides a base structure for a garment embroidery workbench, which includes a workbench base 1, a first embroidery stand 2, a second embroidery stand 3, a connecting bridge 4, a conveyor belt 5, a storage bag 6, an operating chair 7, and a silent fan 8. Copy lamp 9, foot pad 10 and rotating shaft 101; the first embroidery table 2 is installed on the left side panel of the workbench base 1 through the rotating shaft 101; the right side panel of the workbench base 1 is installed through the rotating shaft 101 There is a second embroidery table 3; the workbench base 1 is disconnected in the middle, and the two sections of the workbench base 1 are connected to each other through a connecting bridge 4; a conveyor belt 5 is movably installed on the connecting bridge 4; the workbench base 1. The bottom ends of the left and right sides are respectively connected by slide rails and an operating chai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap