Gap Adjustment Technology for Steel Beam Closing

A gap adjustment, steel beam technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of bridge alignment and internal force influence, large temperature influence, difficult to accurately control the amount of jacking, and achieve strong adaptability , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

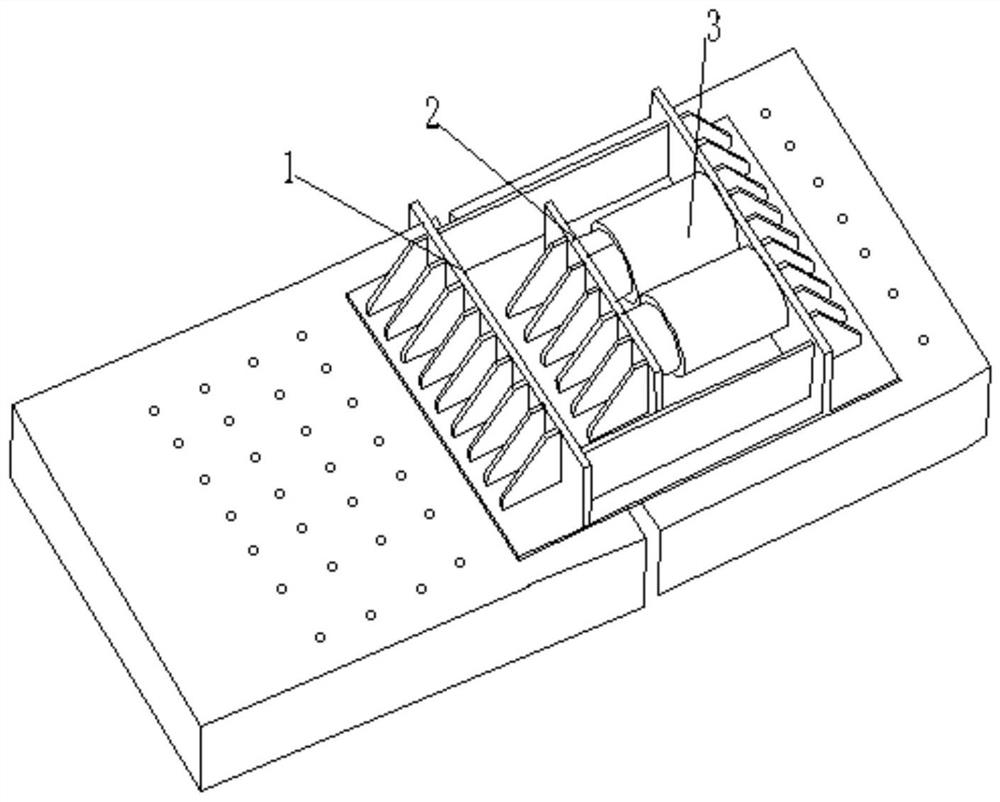

[0037] In Example 2, when the gap between the steel girders at the closing mouth is large and does not meet the design requirements, in order to ensure smooth closing, the gap between the steel girders needs to be adjusted smaller, such as figure 2 As shown, place the jack 3 at the position shown in the figure, and then start the jack 3.

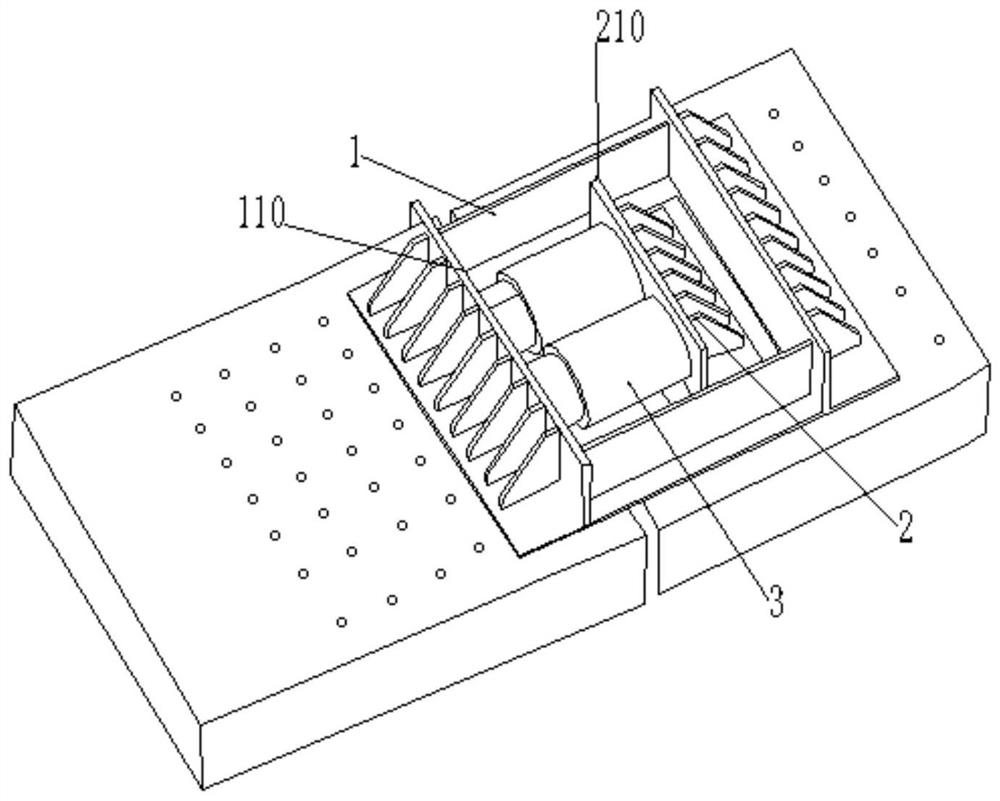

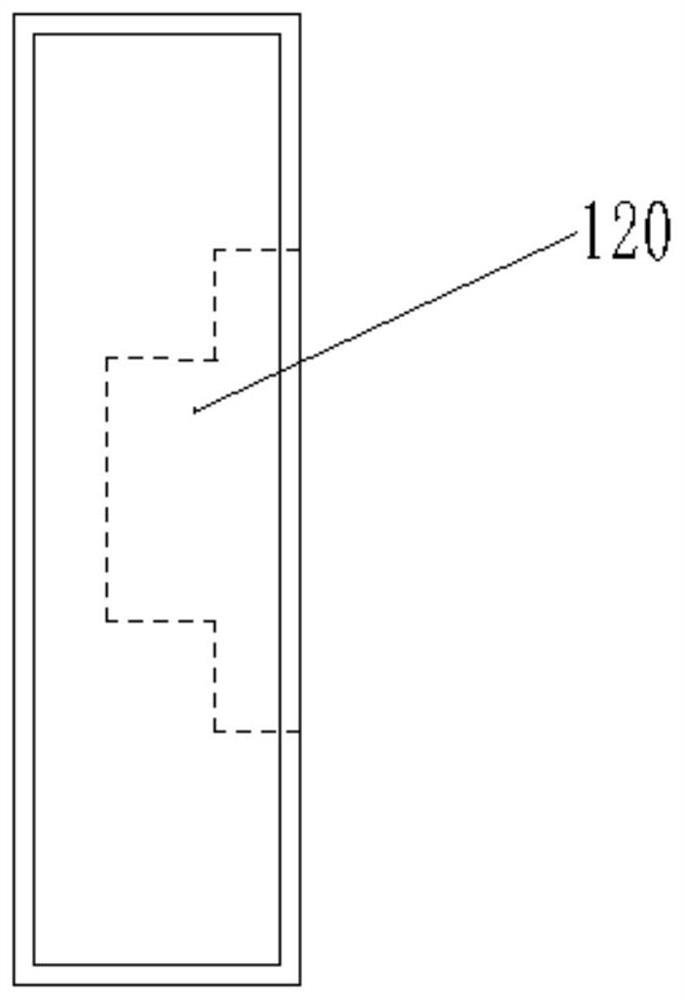

[0038] In another embodiment, such as figure 1 As shown, the A reaction force seat 1 has a frame structure, and the B reaction force seat 2 has a block structure; the A reaction force seat 1 has a square frame structure, and one end of the square frame structure extends outward to form a transverse diaphragm 110, when the A reaction force base 1 is laterally fixed on the steel beam, the a transverse diaphragm 110 is perpendicular to the surface of the steel beam, and is used to offset one end of the jack; one end of the B reaction force seat 2 faces The outer extension forms a b-diaphragm 210 , and when the B-reaction seat 2 is laterally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com