Formation method of deep development system

It is a deep and lifting system technology, which is applied in earth drilling, surface mining, underground mining, etc. It can solve the problems of large engineering quantity and construction investment, failure of the development system to operate normally, and failure of the mine to maintain normal production. The effects of liquidity, promising market prospects, and shortening the infrastructure cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

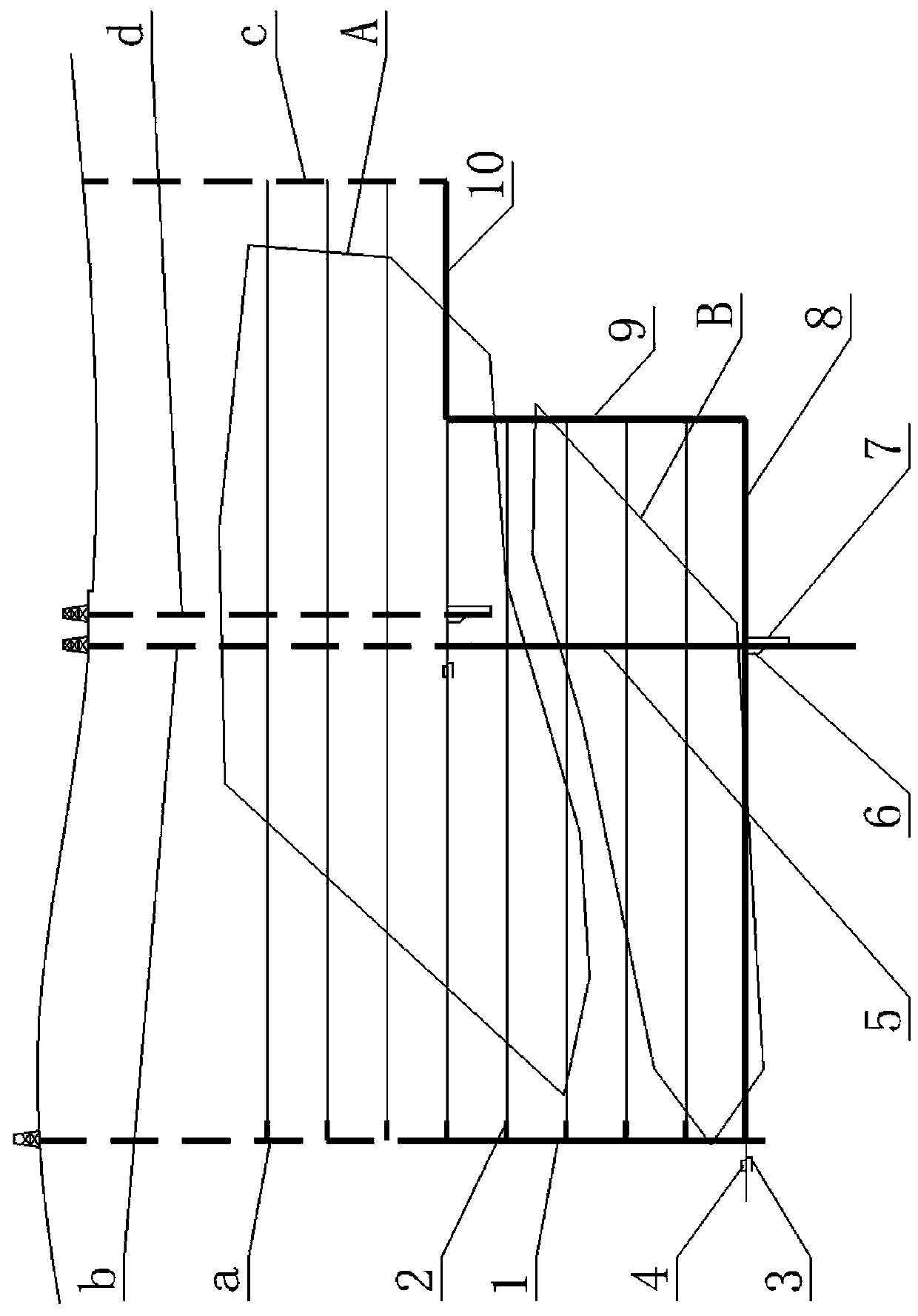

[0024] From figure 1 It can be seen that the forming method of this deep development system of the present invention comprises the following steps:

[0025] (1) Extend the air shaft a in the mine’s original development system A down to the lowest service middle section, and refit the air shaft to become a new auxiliary shaft 1; when the mine’s original development system A has multiple air shafts, according to the deep ore body Occurrence range, inclination and extension orientation, comprehensively select the most extensive coverage of the deep ore body and the nearest wind shaft extension to be converted into a new auxiliary shaft 1;

[0026] During the extension and modification of wind shaft a, it is necessary to form supporting works including the horse head gate 2 in the middle section, the central water tank 3 at the bottom of the shaft and the central water pump room 4, and complete the installation of shaft equipment, mechanical equipment, cables and pipelines;

[00...

Embodiment 2

[0033] From figure 1 It can be seen that the forming method of this deep development system of the present invention comprises the following steps:

[0034] (1) Extend the air shaft a in the mine’s original development system A down to the lowest service middle section, and refit the air shaft to become a new auxiliary shaft 1; when the mine’s original development system A has multiple air shafts, according to the deep ore body Occurrence range, inclination and extension orientation, comprehensively select the most extensive coverage of the deep ore body and the nearest wind shaft extension to be converted into a new auxiliary shaft 1;

[0035] During the extension and modification of wind shaft a, it is necessary to form supporting works including the horse head gate 2 in the middle section, the central water tank 3 at the bottom of the shaft and the central water pump room 4, and complete the installation of shaft equipment, mechanical equipment, cables and pipelines;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com