Staged supercharged combustion solid rocket motor

A solid rocket and engine technology, applied in the field of aerospace science, can solve the problems of high gas temperature, engine adiabatic structure, and unstable influence of negative mass combustion, so as to improve the working time, reduce the design quality, and improve the structural quality and large size of the engine casing. The effect of thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

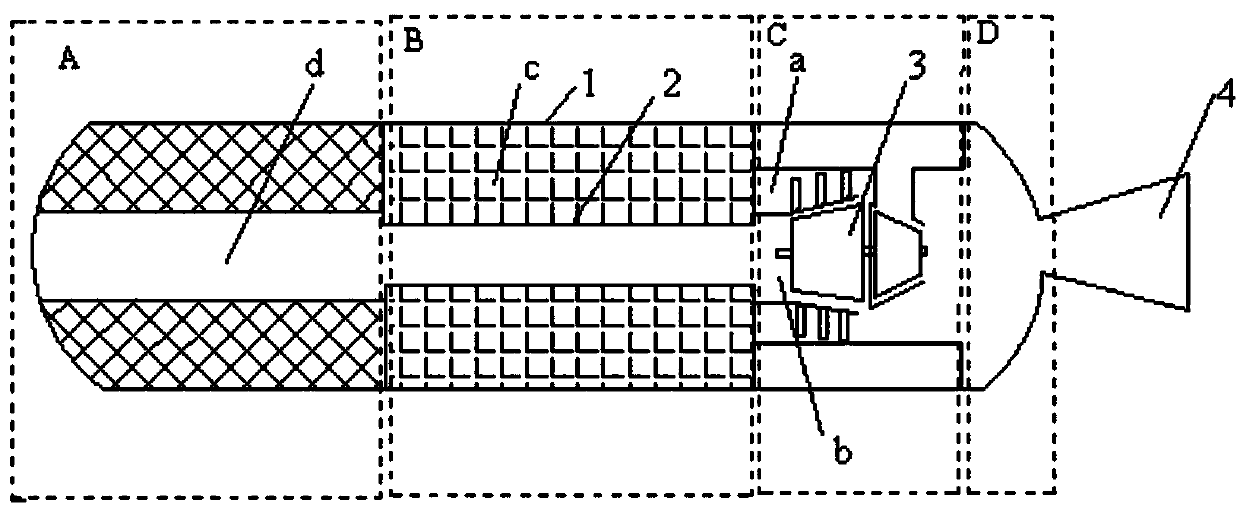

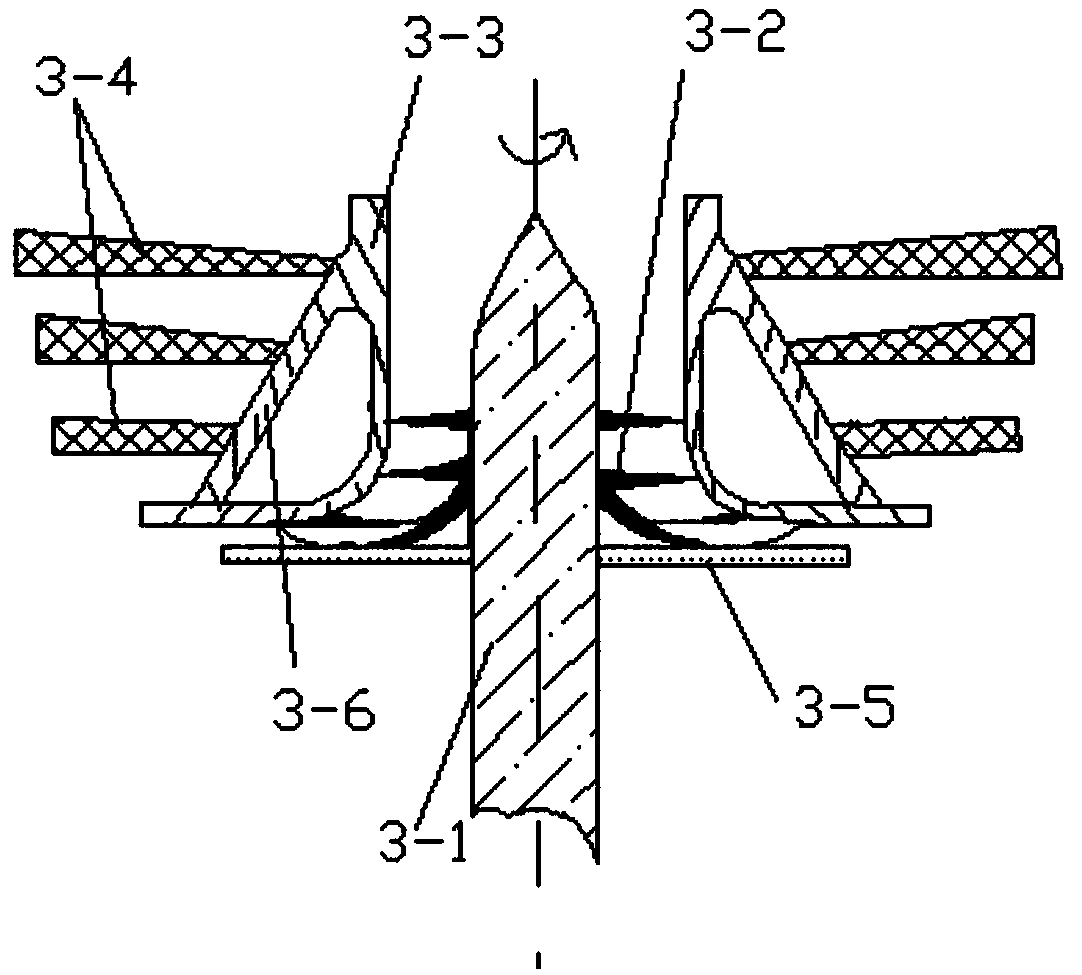

[0016] The present invention staged pressurized combustion solid rocket motor, such as figure 1 As shown, it includes the previous combustion chamber A, the rear combustion chamber B, the booster chamber C and the main combustion chamber D which are sequentially connected in the axial direction, and the rear end of the main combustion chamber D is used to connect with the nozzle pipe 4, wherein One primary combustion chamber is used to fill the oxygen-enriched propellant, the other is used to fill the rich-burn propellant, which is used for the first combustion of the corresponding propellant; the pressurization chamber C is provided with an external pressurization channel a and an internal booster Pressure channel b, they are all arranged in the axial direction, and coaxially sleeved together; the inner pressurization channel b communicates with the previous combustion chamber A and the main combustion chamber d in the axial direction, pressurizes the air flow passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com