Aluminum profile with good heat dissipation effect

A heat dissipation effect and aluminum profile technology, which is applied in the field of aluminum profiles, can solve the problems of slow heat dissipation of radiators and achieve the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

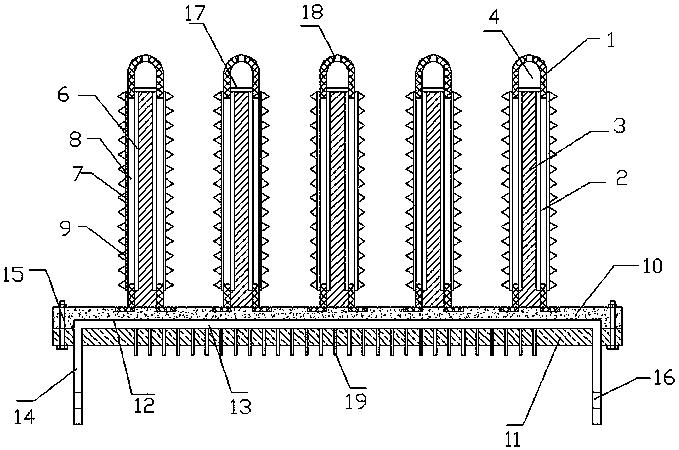

[0023] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

[0024] As shown in the figure, an aluminum profile with good heat dissipation effect, including a base, a heat sink and a fixing frame;

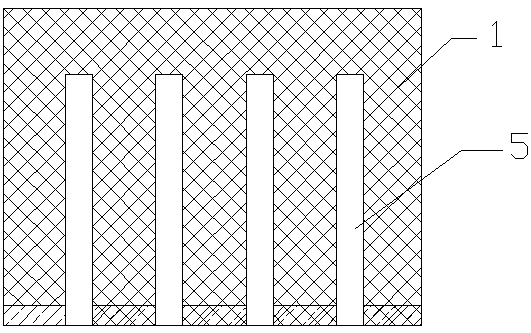

[0025] The heat sink includes a heat sink shell 1, a heat dissipation assembly 2 and a plug plate 3. The heat sink shell is provided with a socket cavity 4 with an open bottom, and the two side walls of the heat sink shell are respectively provided with a plurality of first plug sockets parallel to each other. slot 5;

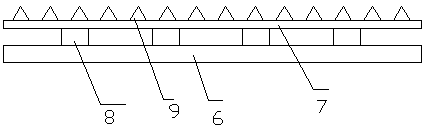

[0026] The number of heat dissipation components is two, and the heat dissipation components include an inner heat dissipation plate 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com