Cantilever structure with anti-collision and puncture functions

A technology of puncture needles and needle arms, which is applied in the field of accessories for testing equipment, and can solve the problem that the anti-collision strength of puncture needles cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

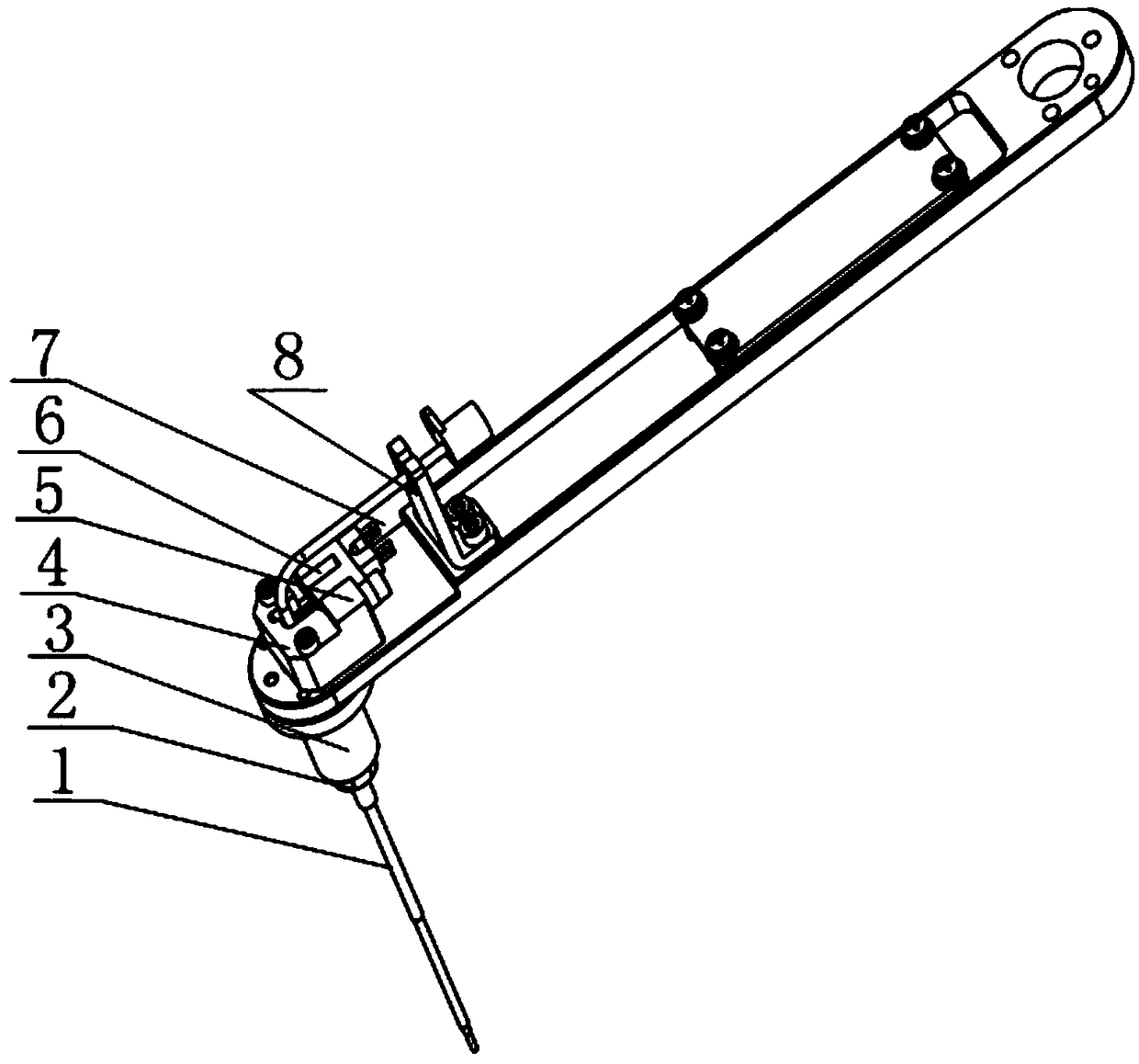

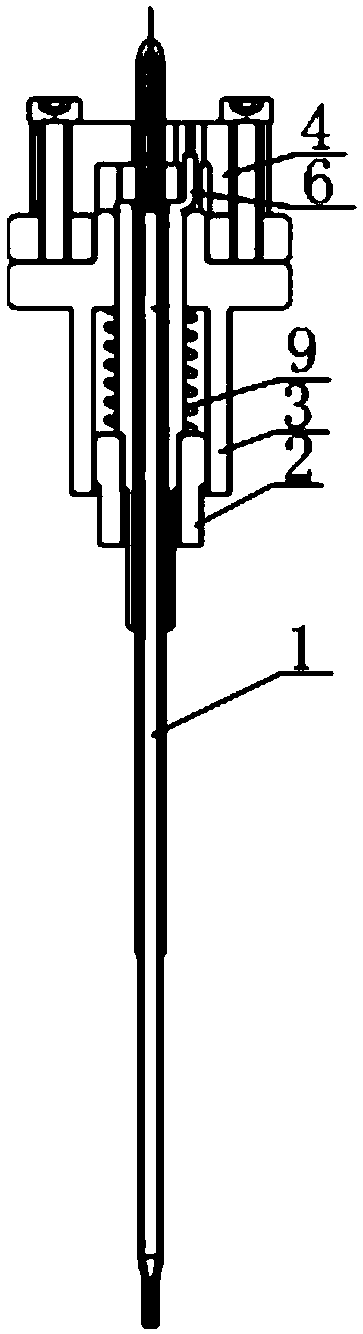

[0032] Such as figure 1 — Figure 8 As shown, a needle arm structure with anti-collision puncture function, including puncture needle 1, limit post 2, guide sleeve 3, sensor holder 4, photoelectric switch 5, needle induction sheet 6, compression spring 9, guide sleeve 3 Installed on the lower end of the sensor holder 4, the puncture needle 1 passes through the center of the sensor holder 4 and the guide sleeve 3 sequentially from top to bottom, a cavity is formed between the inner wall of the guide sleeve 3 and the outer wall of the puncture needle 1, and the compression spring 9 Set in the cavity, the limit column 2 is located at the lower end of the cavity and is detachably connected with the outer wall of the puncture needle 1, the limit column 2 can move upward together with the puncture needle 1 to compress the compression spring 9; the puncture needle 1 is provided with a needle The sensing sheet 6 and the needle sensing sheet 6 are located at the lower end of the photo...

Embodiment 2

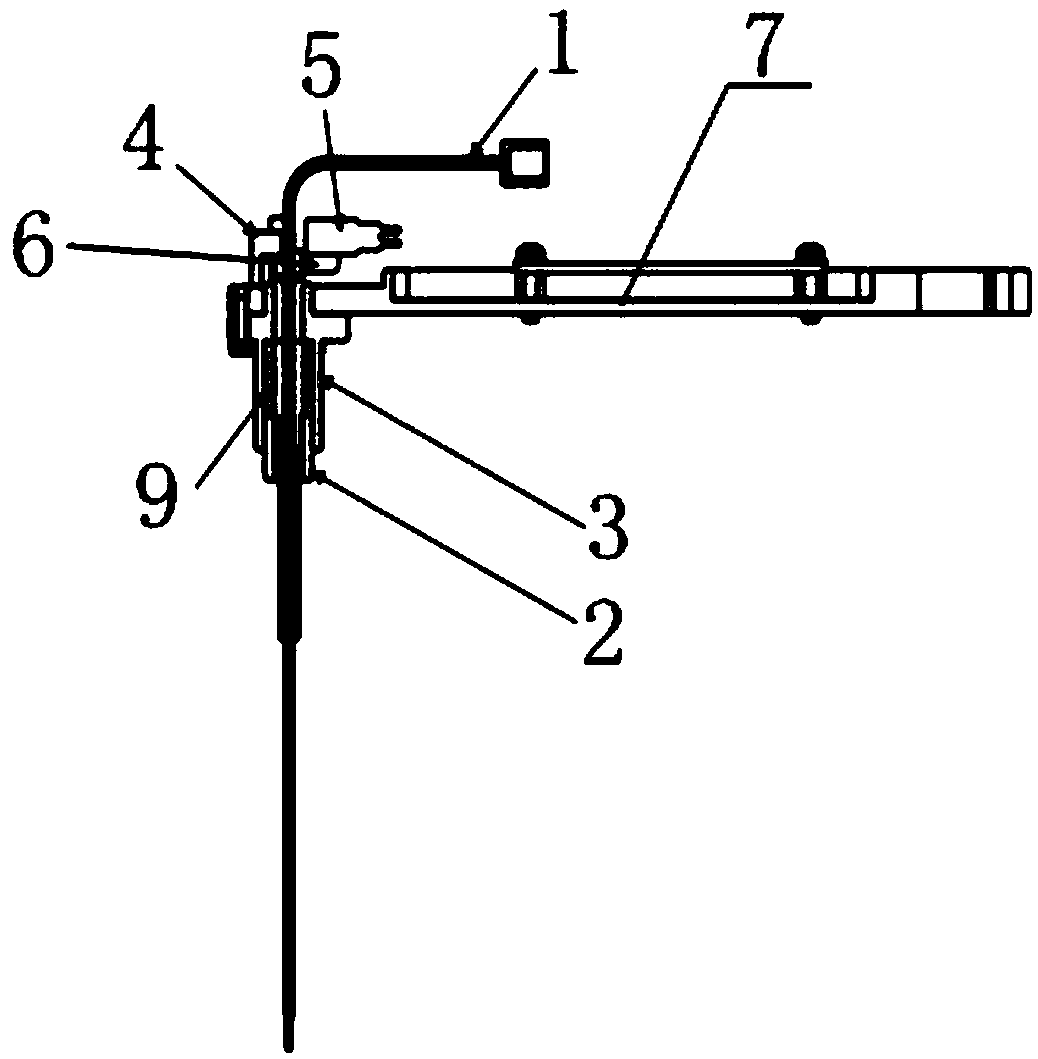

[0043] The difference between this embodiment and Embodiment 1 is that the sensor fixing seat 4 is a block structure with a quadrilateral cross section, and the central area of the sensor fixing seat 4 is provided with a through hole that facilitates the passage of the puncture needle 1, and the sensor is fixed Seat 4 is fixed with support plate 7 by bolt. The support plate 7 is located between the sensor fixing seat 4 and the guide sleeve 3 , and the support plate 7 is provided with a through hole 2 communicating with the through hole 1 . The second through hole on the support plate 7 communicates with the first through hole, the guide sleeve 3 and the limit post 2 to form a passage for the puncture needle 1 to pass through. The centerlines of the first through hole, the second through hole, the guide sleeve 3 and the limit post 2 coincide, that is, the center is on a straight line, which is convenient for the movement of the puncture needle 1 .

[0044] The concrete struc...

Embodiment 3

[0049] The difference between this embodiment and the above-mentioned embodiments is that there is a gap between the compression spring 9 and the puncture needle 1 . In this embodiment, the compression spring 9 is sheathed on the outer periphery of the puncture needle 1. The puncture needle 1 has a guiding effect on the compression spring 9, and can ensure that the rebound force of the compression spring 9 is always kept in the vertical direction without deflection. At the same time, the gap between the compression spring 9 and the puncture needle 1 can ensure that the normal compression of the compression spring 9 is not affected by the friction of the puncture needle 1 or the guide sleeve 3, avoiding the reduction and loss of the elastic force of the compression spring 9, and avoiding the occurrence of The compression spring and the matching parts are stuck and cannot be recovered.

[0050] In this embodiment, the optimization of the connection relationship between the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com