Carbon alloy steel in SiMnNiMoV system, lifting ring of drilling machine, and manufacturing method of lifting ring

A technology of carbon alloy steel and manufacturing method, which is applied in the field of drilling rig suspension rings and its manufacture, SiMnNiMoV series medium carbon alloy steel, which can solve the problems of suspension ring steel toughness and plasticity limitations, difficulty in significantly improving, high manufacturing cost, etc., and achieve the elimination of residual stress , Reduce the electroslag remelting link, avoid the effect of temper brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

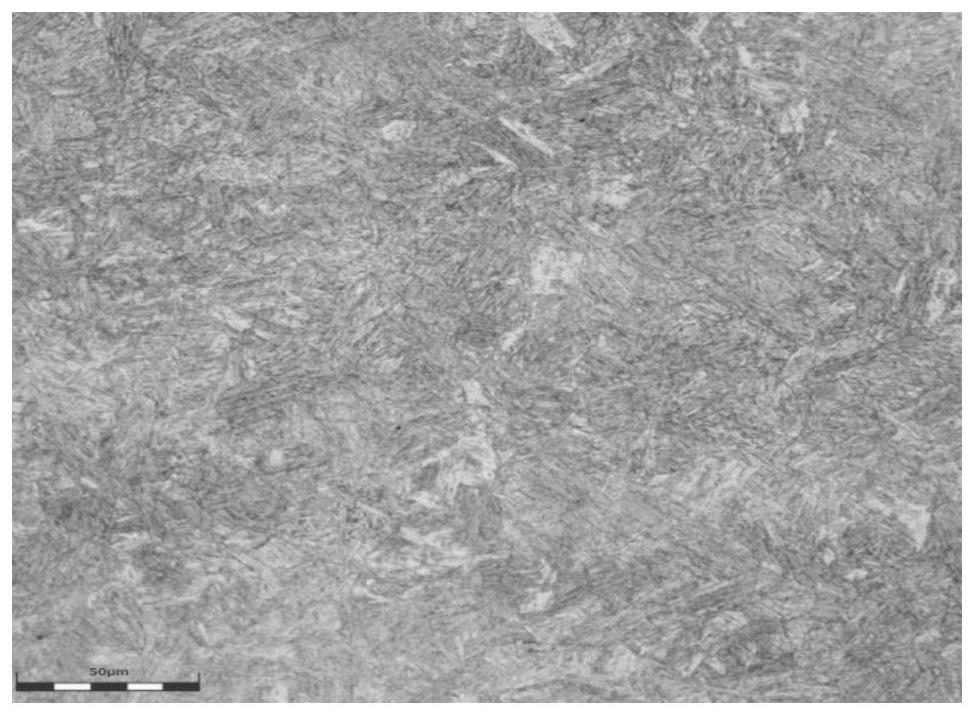

Embodiment 1

[0033] A method of manufacturing a suspension ring, comprising the steps of:

[0034] (1) carry out refining by the medium carbon steel of embodiment 1 in table 1, obtain 700mm diameter billet ingot, by mass percentage, the medium carbon steel of embodiment 1 comprises following component:

[0035] C: 0.25%; Si: 1.1%; Mn: 1.0%; Cr: 0.3%; Mo: 0.5%; Ni: 2.3%; P: 0.01%, [H]: 1ppm, the rest is iron and unavoidable impurities;

[0036] (2) Heating the billet ingot to 1250°C for forging, the forging termination temperature is controlled at 900°C, and the round steel with a diameter of 340-348mm is obtained by forging. After the forging is completed, when the surface temperature drops to 450°C, furnace cooling is carried out;

[0037] (4) The round steel is reheated to 1250°C for forging, the forging termination temperature is controlled at 900°C, and a suspension ring sample with a diameter of 130-140mm is obtained;

[0038] (5) Heat the suspension ring sample to 970°C, keep it wa...

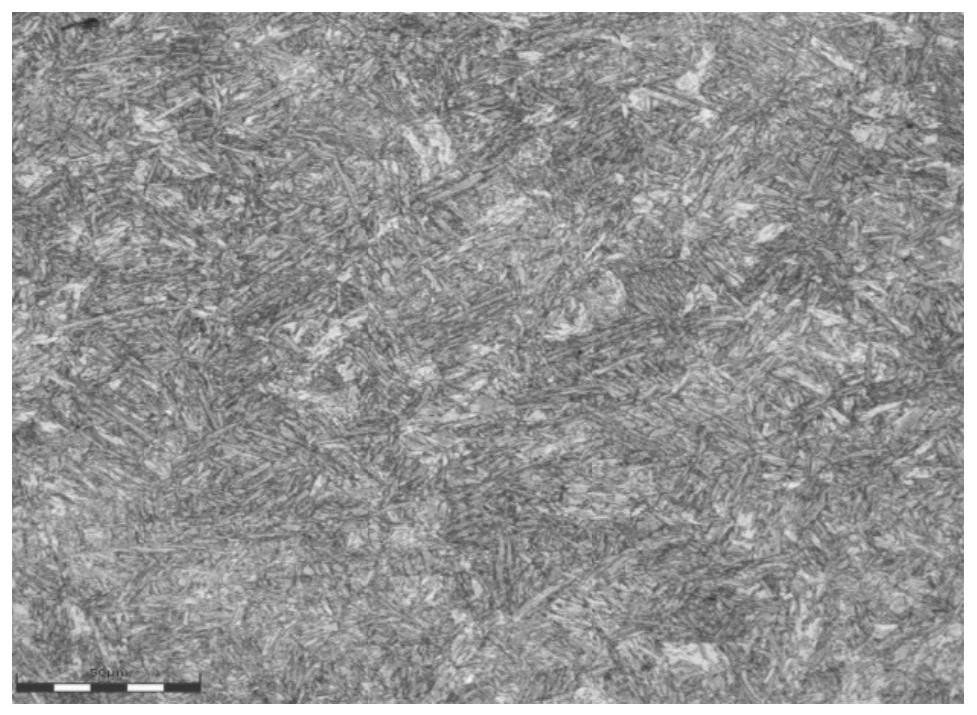

Embodiment 2

[0041] A method of manufacturing a suspension ring, comprising the steps of:

[0042] (1) carry out refining by the medium carbon steel of embodiment 2 in table 1, obtain 800mm diameter billet ingot, by mass percentage, the medium carbon steel of embodiment 2 comprises following component:

[0043] C: 0.28%; Si: 0.9%; Mn: 0.8%; Cr: 0.2%; Mo: 0.6%; Ni: 2.4%; P: 0.006%, [H]: 0.5ppm, and the rest are iron and unavoidable impurities.

[0044] (2) Heating the billet ingot to 1260°C for forging, the forging termination temperature is controlled at 900°C, and the round steel with a diameter of 345-350 mm is obtained by forging. After the forging is completed, when the surface temperature drops to 460°C, the furnace cold;

[0045] (4) Reheat the round steel to 1260°C for forging, the forging termination temperature is controlled at 900°C, and a ring sample with a diameter of 135-145mm is obtained by forging;

[0046] (5) Heat the suspension ring sample to 950°C, keep it warm for 4 ...

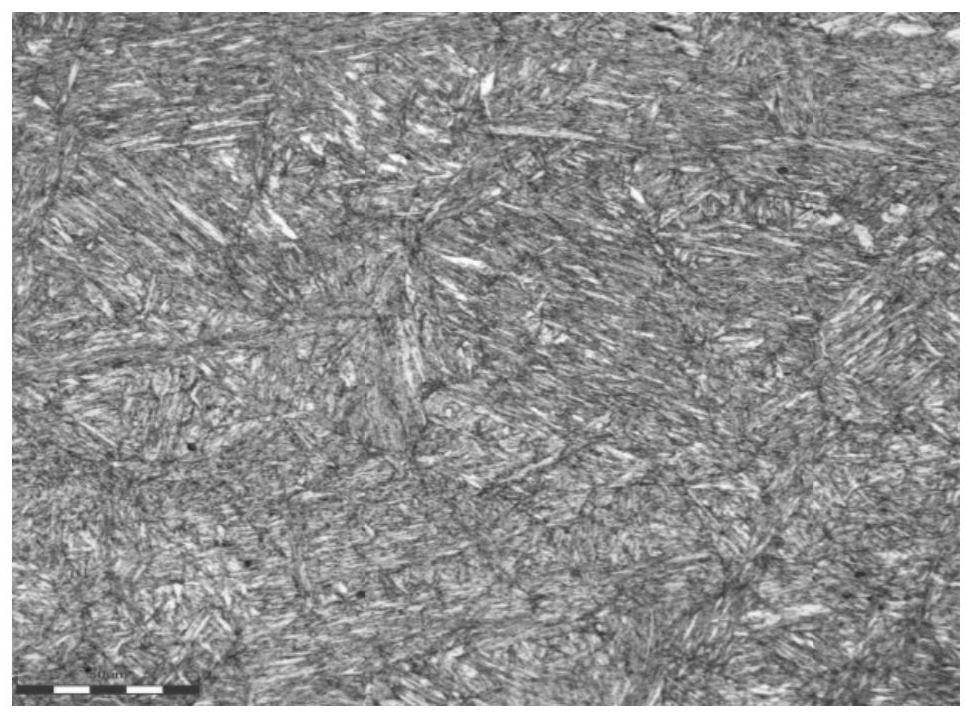

Embodiment 3

[0049] A method of manufacturing a suspension ring, comprising the steps of:

[0050] (1) carry out refining by the medium carbon steel of embodiment 3 in table 1, obtain the billet ingot of 800mm diameter, by mass percentage, the medium carbon steel of embodiment 3 comprises following component:

[0051] C: 0.26%; Si: 1.1%; Mn: 1.1%; Cr: 0.1%; Mo: 0.52%; Ni: 2.1%; P: 0.008%, [H]: 0.8ppm, the rest is iron and unavoidable impurities;

[0052] (2) Heating the steel billet ingot to 1240°C for forging, the forging termination temperature is controlled at 900°C, and the round steel with a diameter of 342-346mm is obtained by forging. After the forging is completed, the surface temperature is reduced to 455°C for furnace cooling;

[0053] (4) The round steel is reheated to 1240°C for forging, the forging termination temperature is controlled at 900°C, and a suspension ring sample with a diameter of 140-150mm is obtained by forging;

[0054] (5) Heat the suspension ring sample to 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com