Cutting clamping mechanism and cutting system provided with same

A clamping mechanism and clamping technology, applied in the direction of manufacturing tools, grinding workpiece supports, grinding machines, etc., can solve the problems of small clamping force, uneven cutting surface, affecting cutting quality, etc., and achieve flexible use and balanced force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

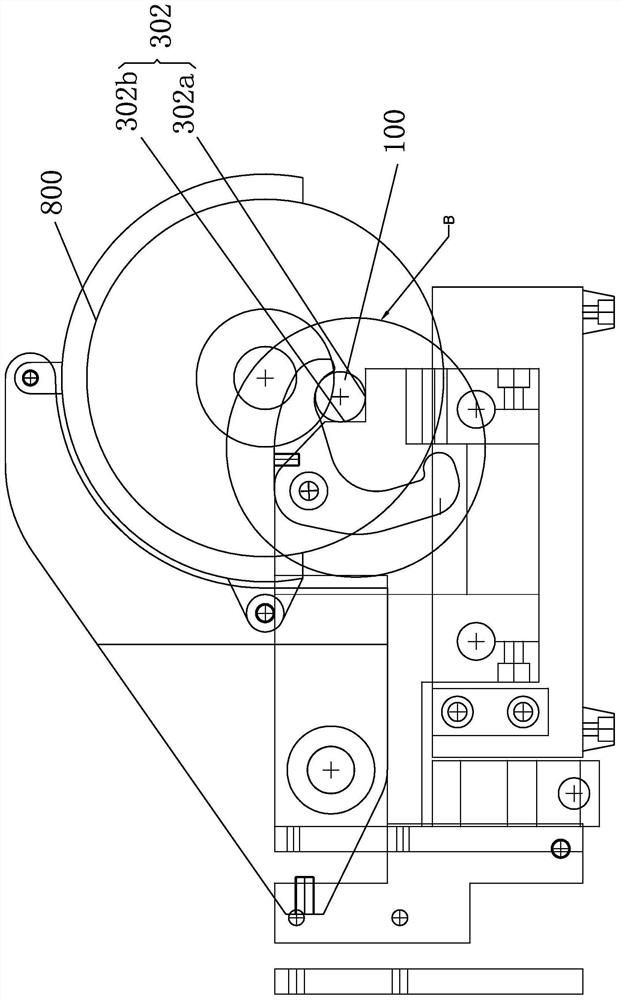

[0028] Such as Figure 1-6 As shown, this case provides a cutting and clamping mechanism for cutting a thimble 100. The thimble 100 includes an adjusting end 101 and a cutting end 102. The adjusting end 101 is moved to adjust the length of the thimble 100, and the thimble 100 meeting the length requirement is cut.

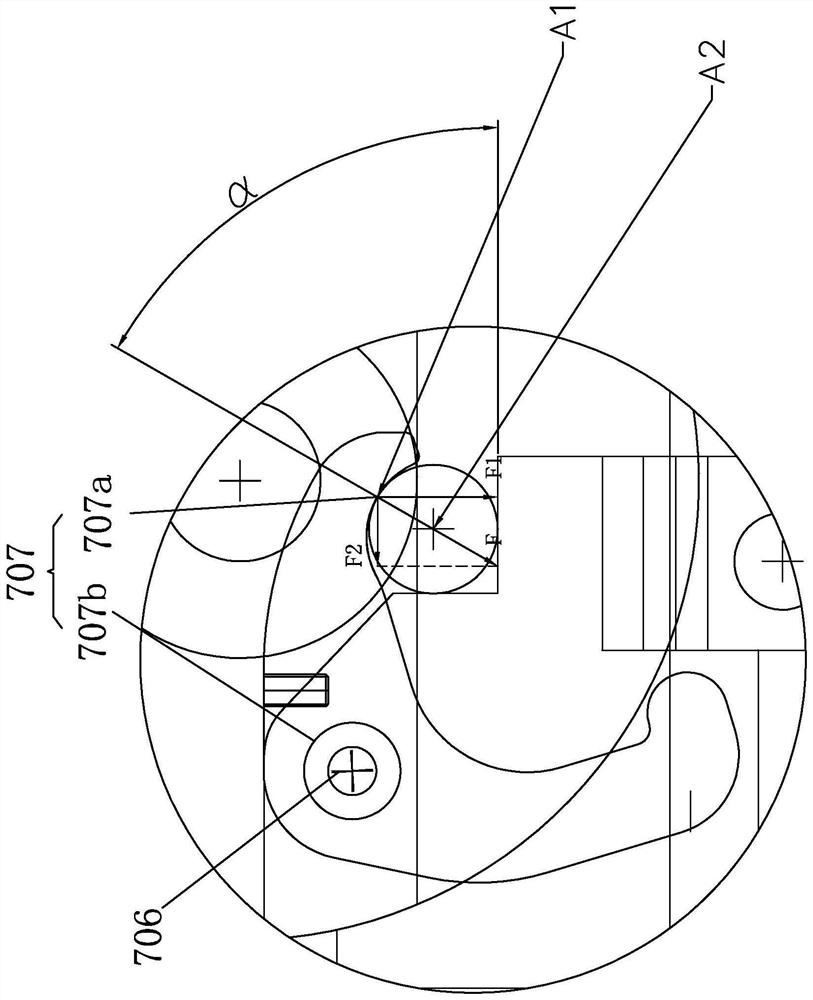

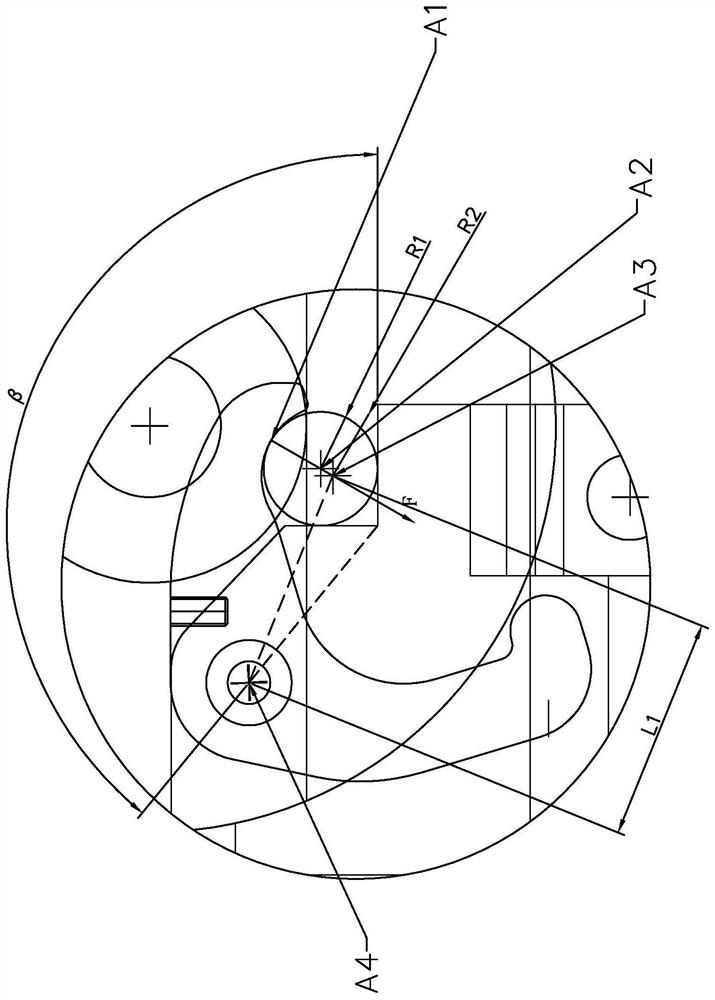

[0029] The cutting and clamping mechanism includes a cutting assembly 800 , a clamping platform 302 , a rotating shaft 706 and a clamping hook 707 . The clamping platform 302 includes a first platform 302a and a second platform 302b. The cutting end 102 of the thimble 100 is clamped on the clamping platform 302 and is tangent to the first platform 302a and the second platform 302b. The clamping platform 302 is opposite to the thimble 100 A rebound force is generated, and the center of the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com