Finalizing method of sprinkling temperature-lowering finalizing device for electric power cable external insulation layer processing

A technology for power cable and outer insulating layer, which is applied in the field of spray cooling and setting device for processing the outer insulating layer of power cable, can solve the problems of unqualified products, inability to touch hard objects, enterprise losses, etc., so as to reduce unqualified products. , Reasonable design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

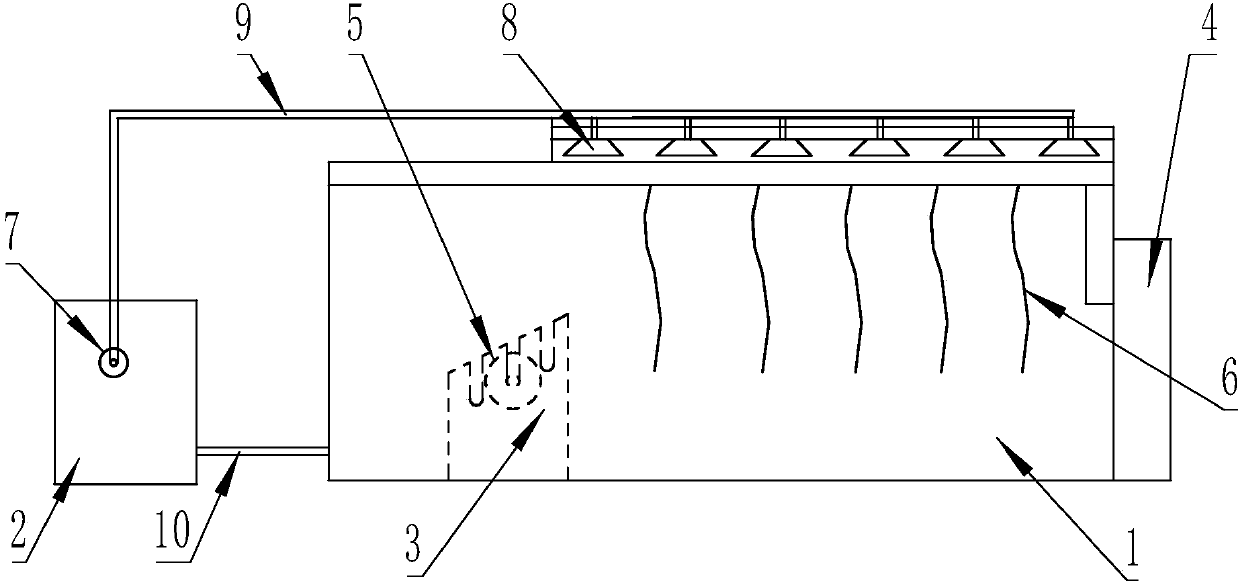

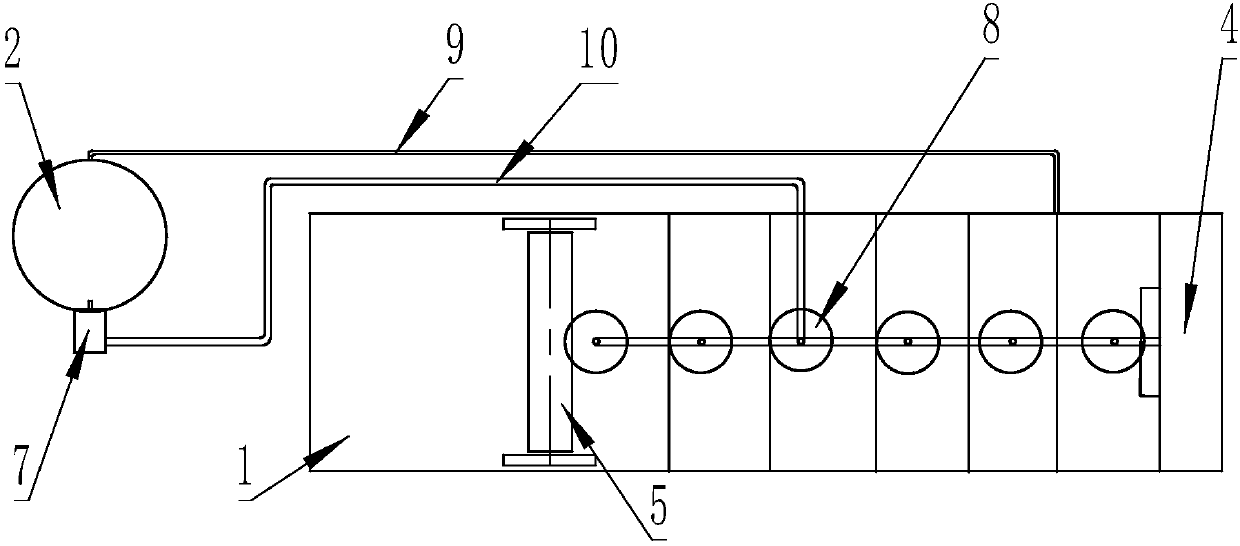

[0018] A spray water heater 2 is installed on one side of the temperature-reducing spray water tank 1, and a circulating water hot water pump 7 is arranged on the upper side of the cylinder of the spray water heater 2, and at least three spray heads 8 are arranged in series in the upper middle part of the temperature-reducing spray water tank 1 It is a pipeline group, and at least three spray heads 8 are spray water hot water pipelines 10 arranged between a pipeline group and the circulating water hot water pump 7; Water collection pipeline 9 is arranged between;

[0019] The outlet end of the temperature-reducing spray water tank 1 is provided with a water tank baffle plate, and an outlet is reserved above the water tank baffle plate. In the water tank at the front of the spray water tank 1, the guide roller positioning frame 3 is arranged symmetrically on both sides, and the cable outlet end guide roller 5 is arranged between the guide roller positioning frames 3 on both sid...

Embodiment 2

[0023] While the power cable passes through the temperature-reducing spray water tank 1, the circulating water hot water pump 7 conveys the water through the spray water hot water pipeline 10 hot water, the hot water continuously sprays hot water through the shower head 8 to all the shower curtains 6 respectively.

Embodiment 3

[0025] The shower curtain 6 is pasted on the soft insulating layer of the power cable after being sprayed with hot water, and the shower curtain 6 cools down the insulating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com