Sampling device for inspection of garment dye production

A sampling device and dye technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of not being able to sample liquid and solid dyes, and the limitations of sampling and sampling, so as to achieve a wide range of device applications, expand diversity, and use range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

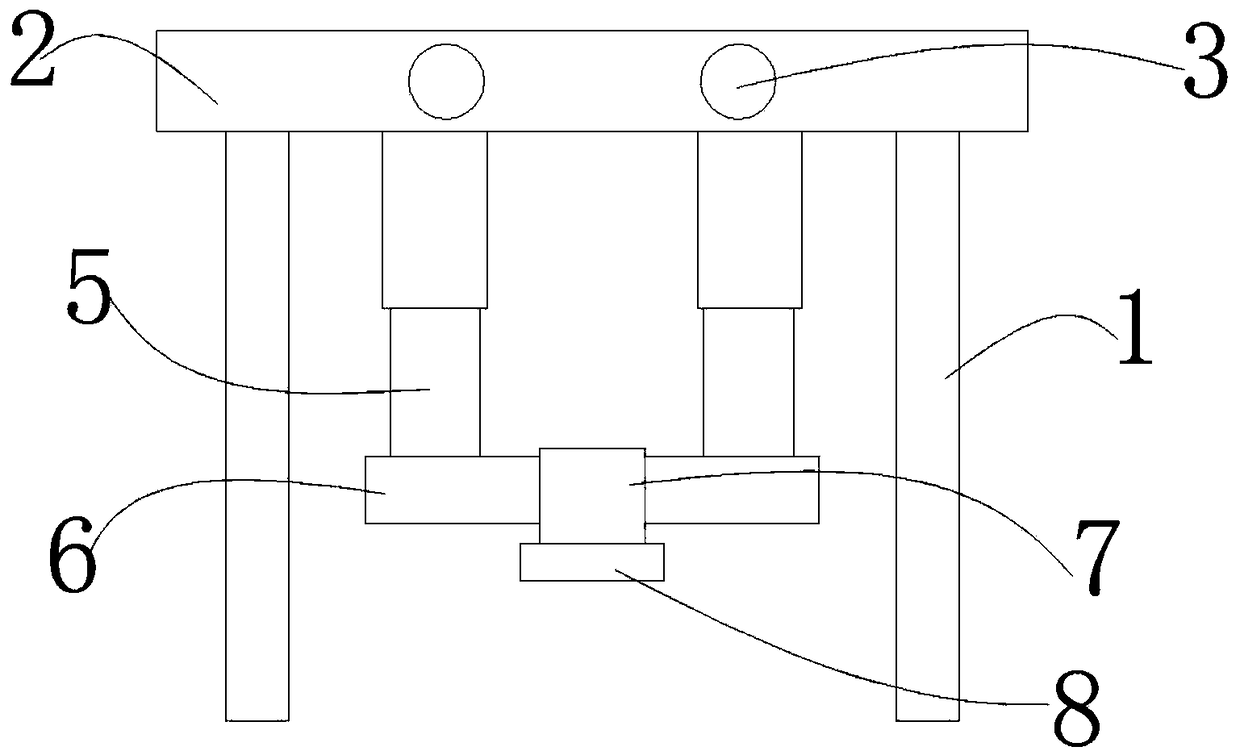

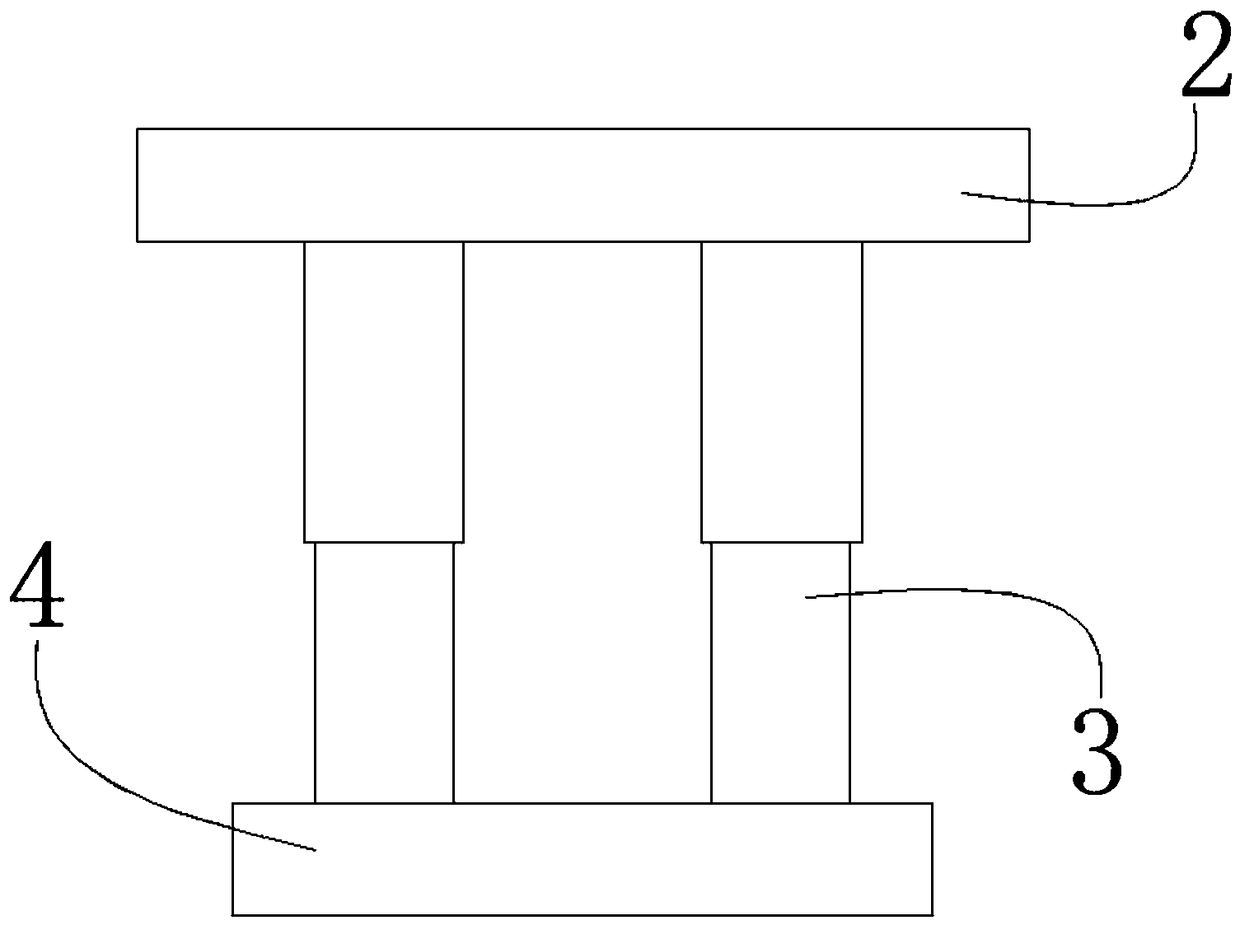

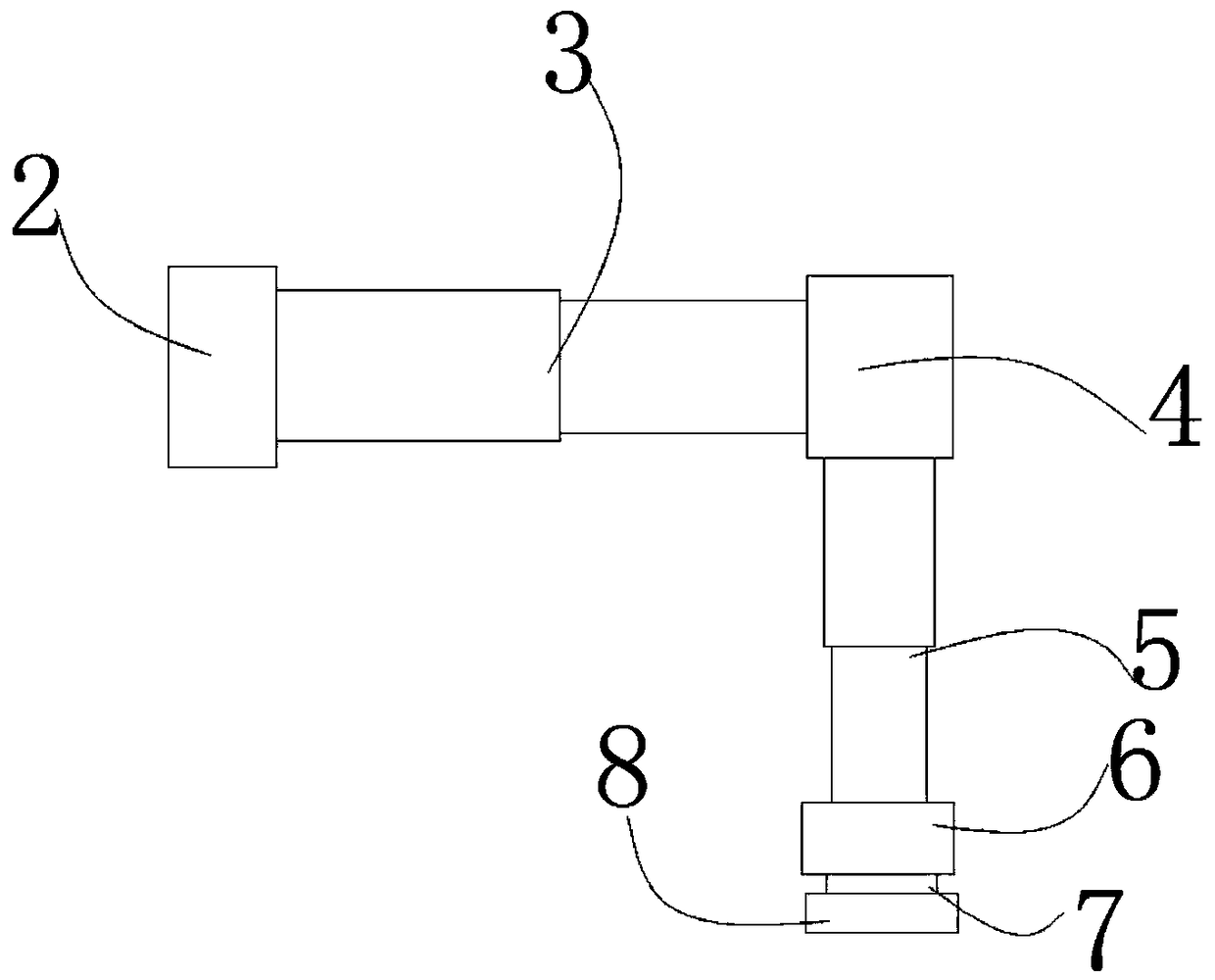

[0026] Embodiment: when using this device to carry out production inspection and sampling of clothing dyes, first power on this device, so that this device can be used under the situation of power on, and then start the switch of the first electric telescopic rod 3, so that the first electric telescopic rod 3 Stretch, the first electric telescopic rod 3 stretches to the upper end of the clothing dye with the connecting plate 2, close the switch of the first electric telescopic rod 3, so that the first electric telescopic rod 3 stops extending, and then start the second electric telescopic rod 5, so that the second electric telescopic rod 5 is extended to the upper end of the dye device, the switch of the second electric telescopic rod 5 is closed, so that the second electric telescopic rod 5 stops extending, and then the beaker is removed from the mounting block 7 Put it into the opening of the beaker so that the opening of the beaker is kept in the same direction as the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com