CLove separating equipment for separating garLic buLbs based on extruding force

A technology of extrusion force and split flap, which is applied in the fields of application, food processing, food science, etc., can solve the problems of flexible gears and flexible stepped tooth sets stuck, equipment not working properly, etc., to achieve improved transmission effect, stable operation, Improve the effect of the split flap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

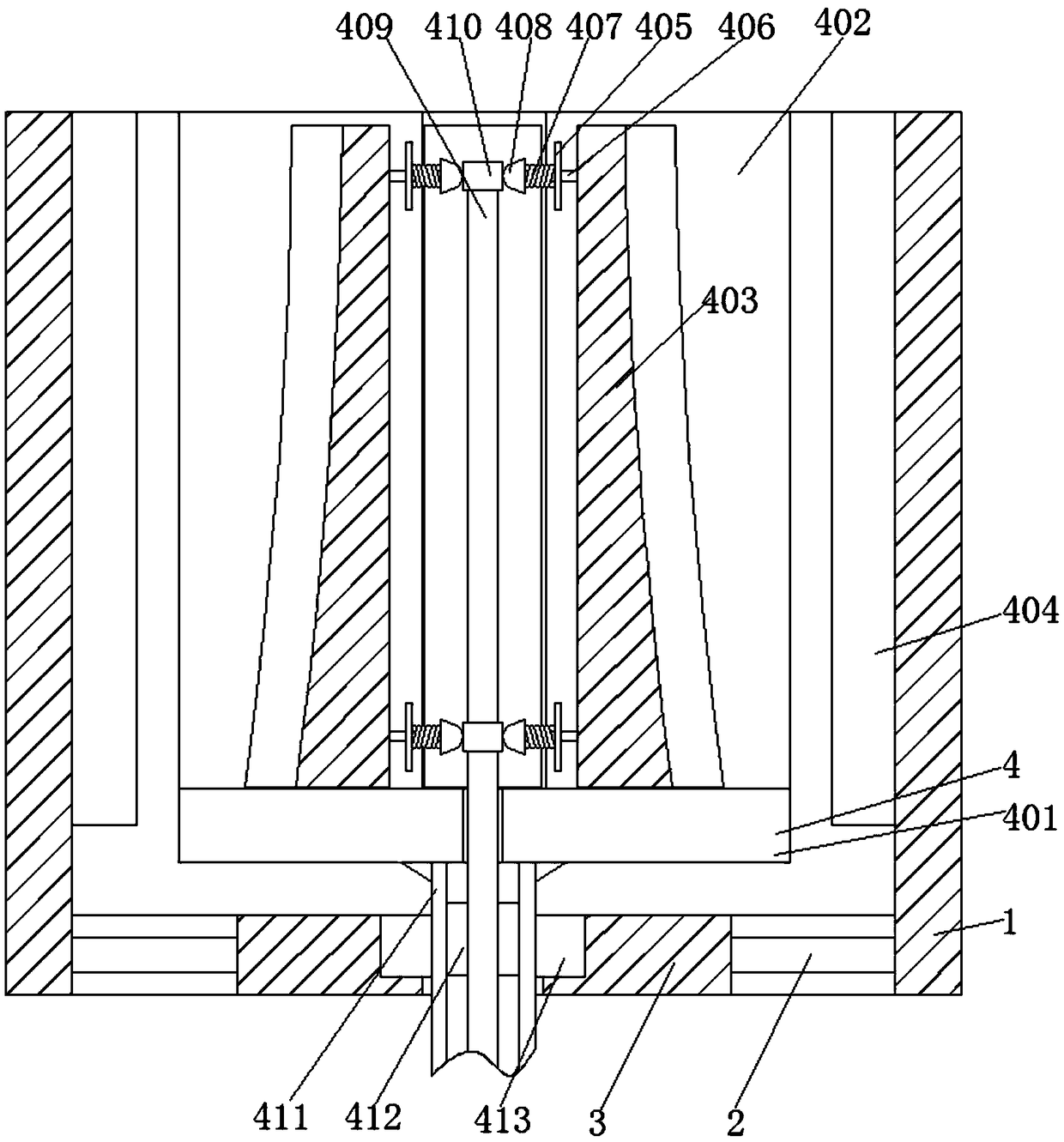

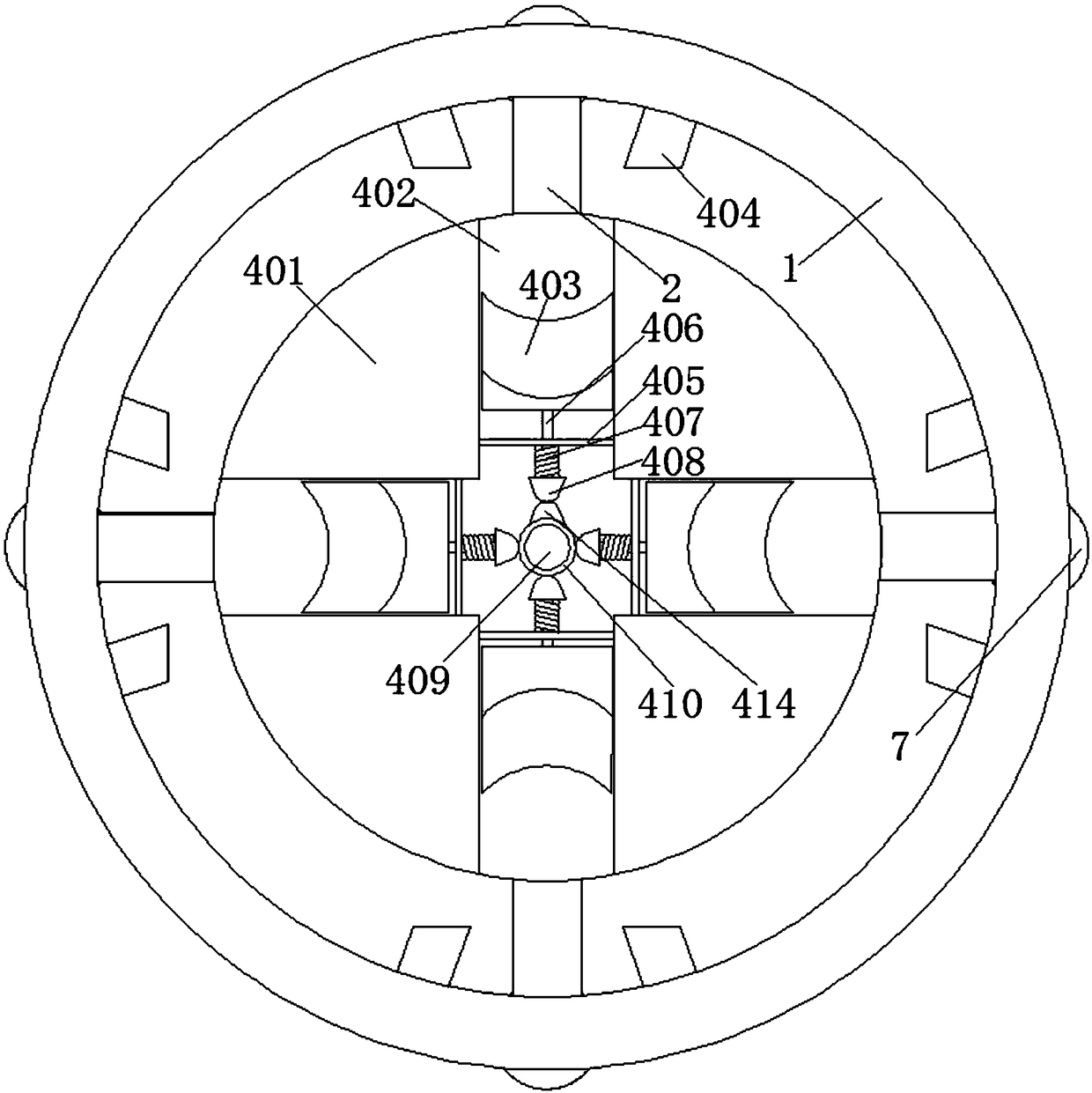

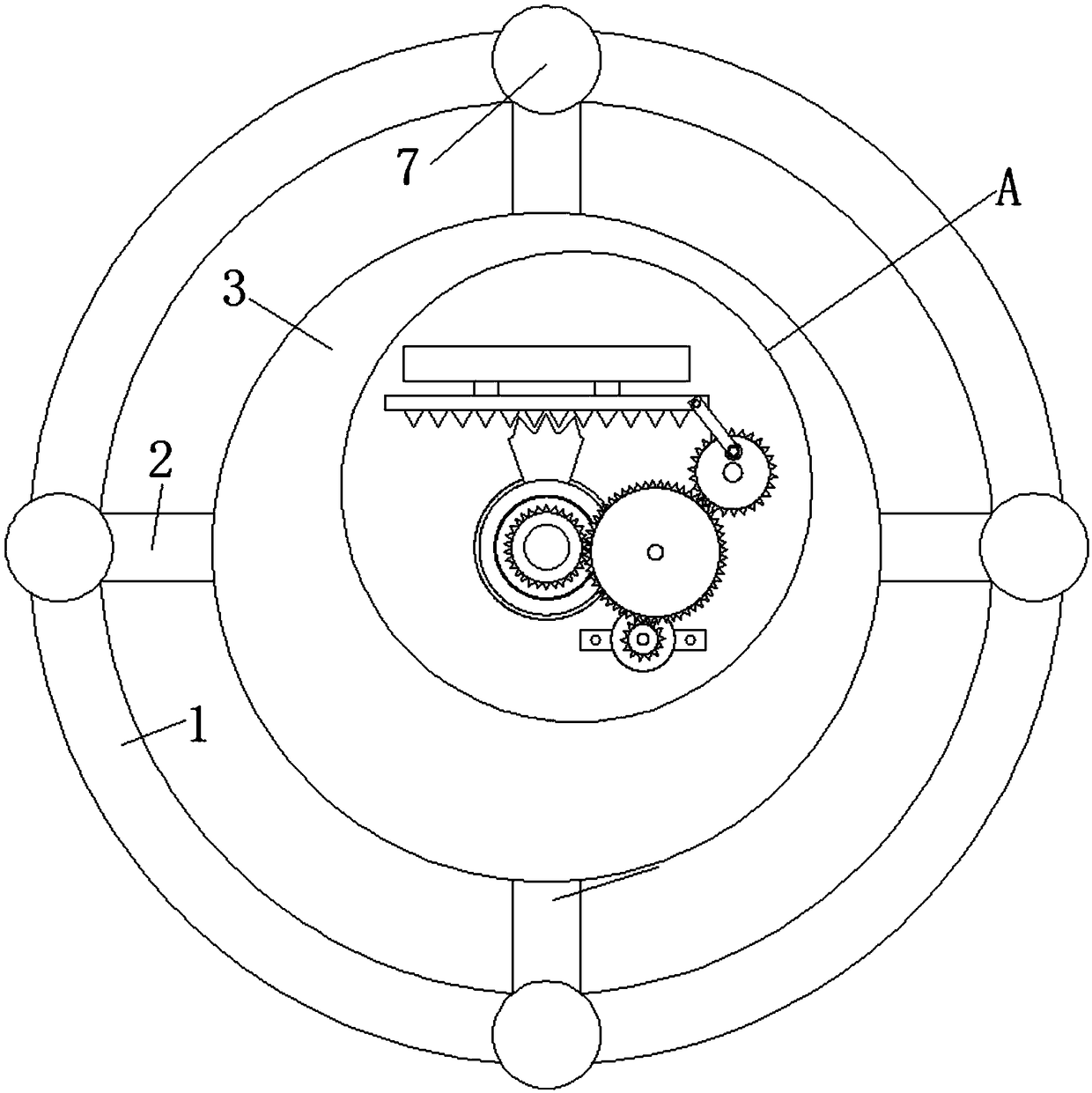

[0034] Embodiments of the present invention provide a splitting device for separating garlic heads based on extrusion force, such as Figure 1-5 As shown, including the separation barrel 1, the top and bottom of the separation barrel 1 are hollow, the inner wall of the separation barrel 1 is fixedly connected with a support rod 2, and the end of the support rod 2 away from the inner wall of the separation barrel 1 is fixedly connected with a round block 3, the separation barrel 1 is provided with a splitting device 4, the bottom of the separation bucket 1 is provided with a transmission device 5, the transmission device 5 is provided with a connecting device 6, and the bottom of the separation bucket 1 is fixedly connected with a support leg 7.

[0035]The splitting device 4 includes a cylinder 401, a cross-shaped slot 402, a movable track block 403, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com