A method for controlling brushing intensity based on pressure detection and electric toothbrush

An electric toothbrush, detection and control technology, used in force/torque/work measuring instruments, dentistry, measuring devices, etc., can solve problems such as brushing strength and unhealthy teeth, and achieve the effect of solving unhealthy teeth and filtering out interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

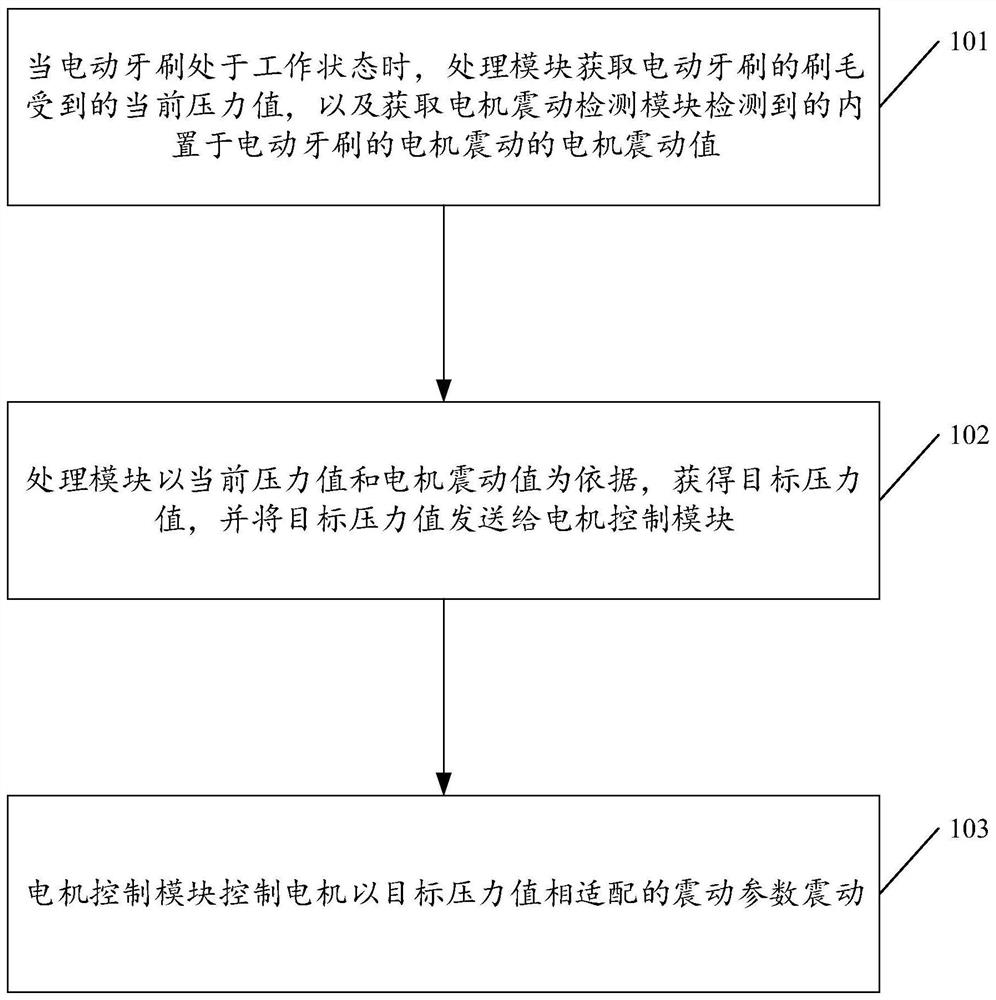

[0061] see figure 1 , figure 1 It is a schematic flow chart of a method for controlling brushing intensity based on pressure detection disclosed in an embodiment of the present invention. Such as figure 1 As shown, the method of controlling brushing intensity based on pressure detection is applied to an electric toothbrush. The electric toothbrush includes a motor vibration detection module, a processing module, and a motor control module; the processing module is electrically connected to the motor vibration detection module, and the processing module is connected to the motor control module. Electrically connected, the method for controlling brushing intensity based on pressure detection may include the following steps:

[0062] 101. When the electric toothbrush is in the working state, the processing module obtains the current pressure value on the bristles of the electric toothbrush, and obtains the motor vibration value of the motor vibration built in the electric tooth...

Embodiment 2

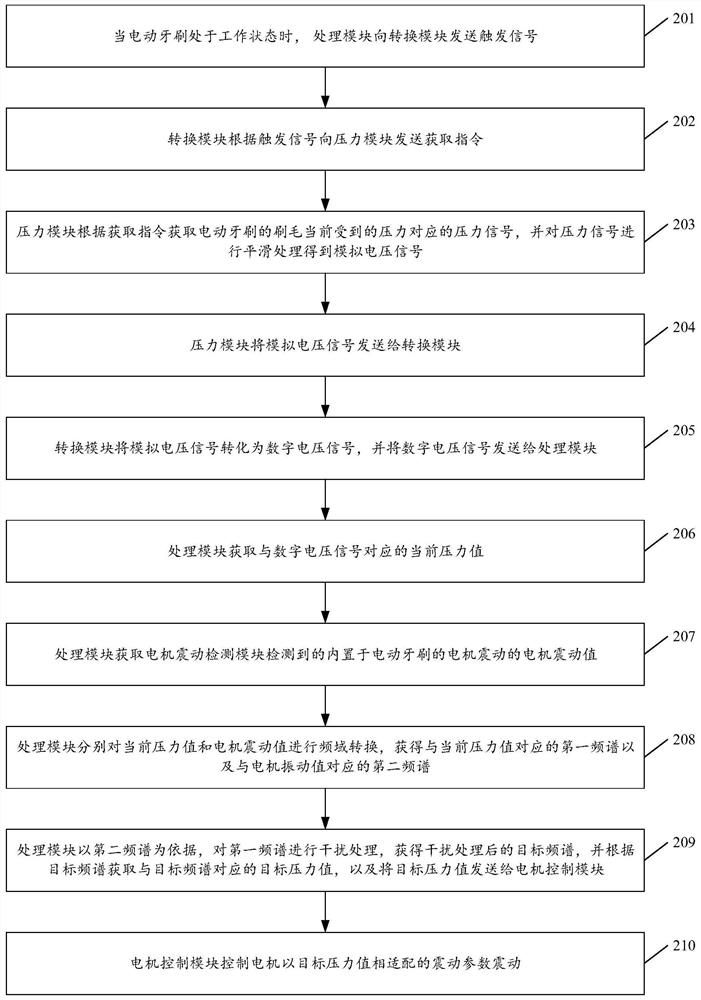

[0082] see figure 2 , figure 2 It is a schematic flow chart of another method for controlling brushing strength based on pressure detection disclosed in the embodiment of the present invention. Such as figure 2 As shown, the method for controlling brushing intensity based on pressure detection is applied to an electric toothbrush. The electric toothbrush includes a motor vibration detection module, a processing module, a motor control module, a pressure module, and a conversion module. The pressure module is electrically connected to the conversion module, and the conversion module It is electrically connected with the processing module, and the pressure module is set on the fixed point of the motor mounting bracket; or, the pressure module is set at the tail of the motor mounting bracket; the processing module is electrically connected with the motor vibration detection module, and the processing module is electrically connected to the motor control module. Connected, th...

Embodiment 3

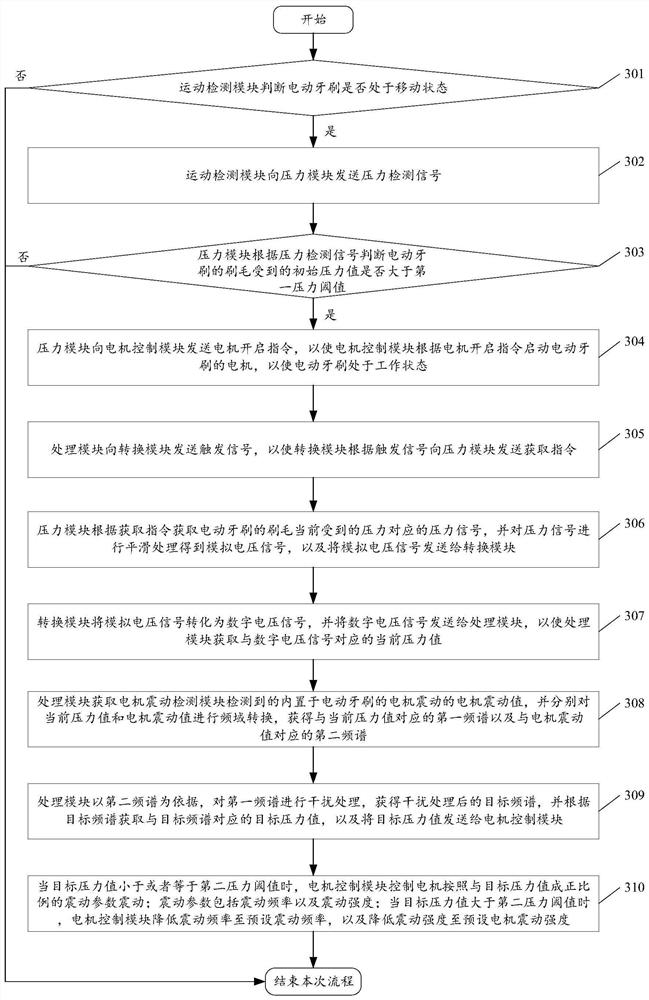

[0104] see image 3 , image 3 It is a schematic flow chart of another method for controlling brushing strength based on pressure detection disclosed in the embodiment of the present invention. Such as image 3 As shown, the method of controlling brushing intensity based on pressure detection is applied to an electric toothbrush. The electric toothbrush includes a motor vibration detection module, a processing module, a motor control module, a pressure module, a conversion module and a motion detection module. The pressure module and the conversion module are electrically connection, the conversion module is electrically connected to the processing module, and the pressure module is set on the fixed point of the motor mounting bracket; or, the pressure module is set at the tail of the motor mounting bracket; the processing module is electrically connected to the motor vibration detection module, and the processing module is connected to the motor The control module is electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com