Dry micro-hot gas filtering system

A filtration system and micro-heating technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles, and can solve the problems of unfavorable ships such as long-term and stable operation of gas equipment and the impact of gas equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

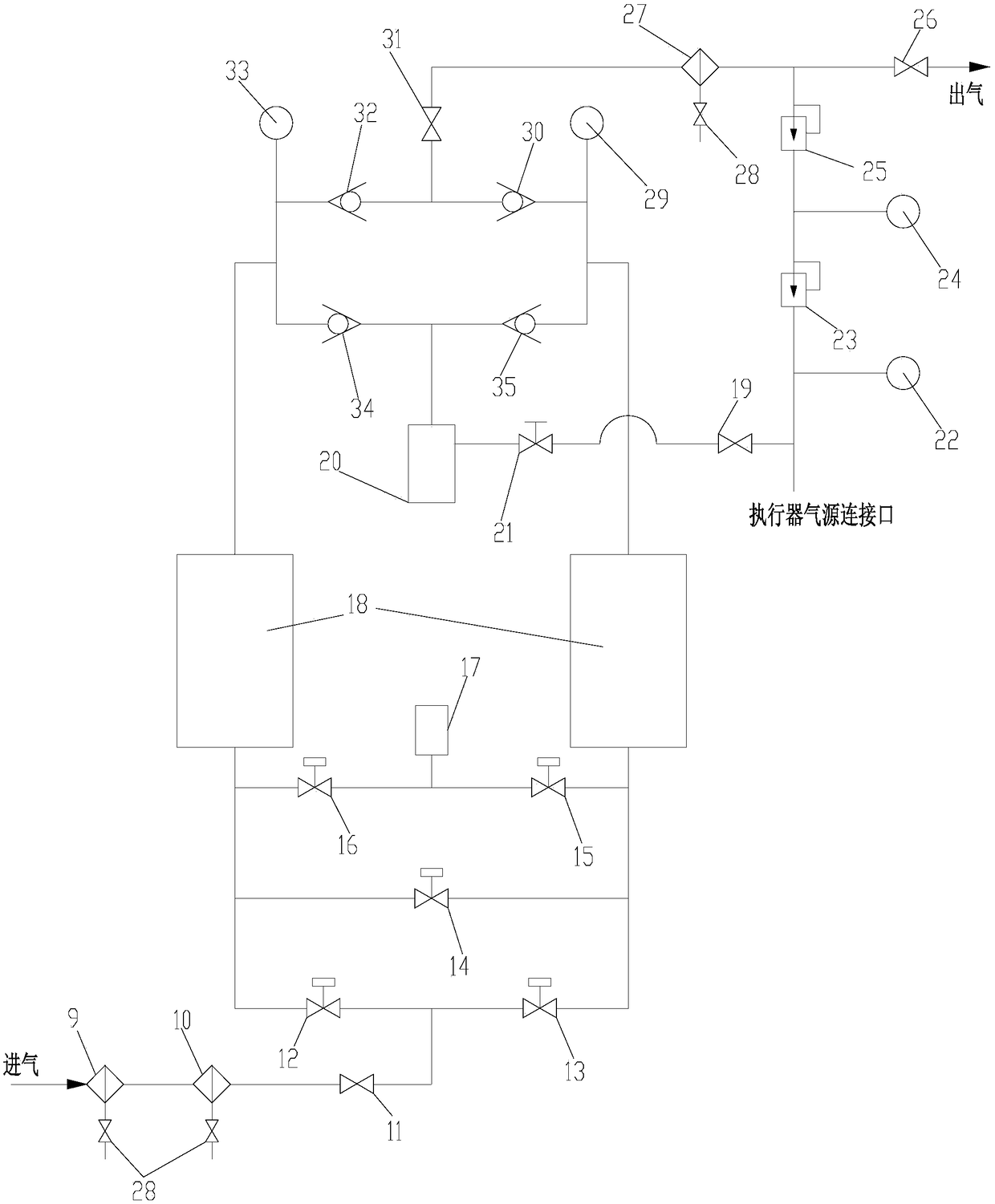

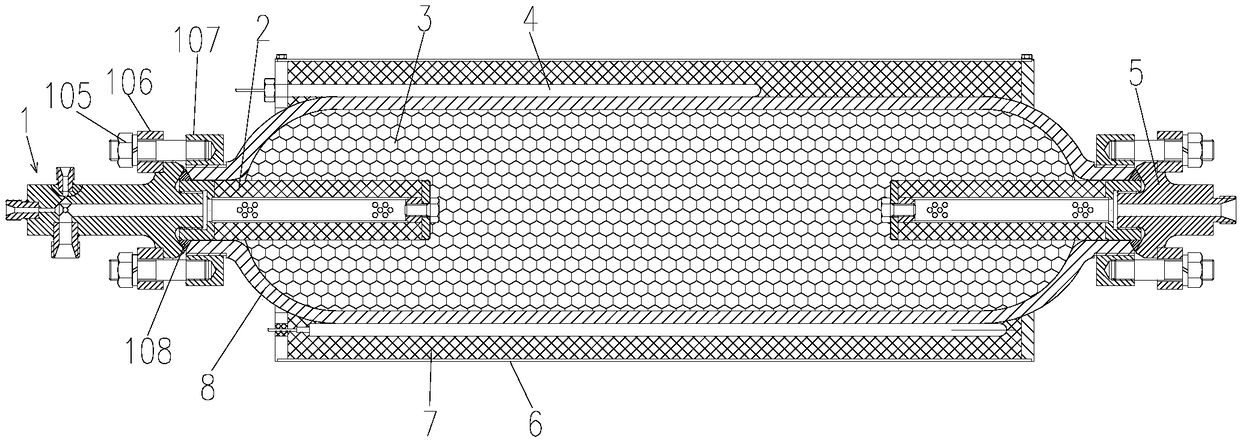

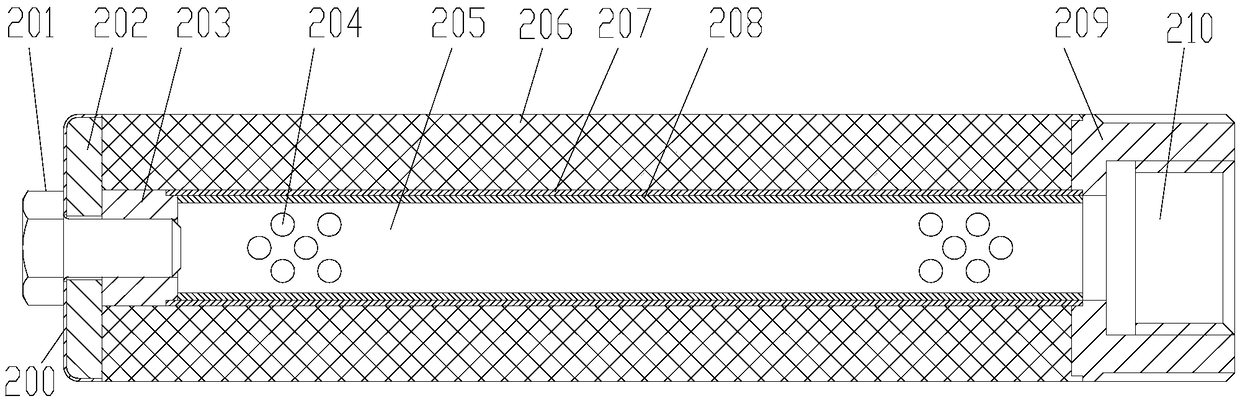

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in the figure:

[0030] A filter system for dry slightly hot gas provided by the present invention includes an input subsystem, an output subsystem and two heating and filtering devices with the same structure;

[0031] The input end of the input subsystem is connected with the output end of the air compressor, that is to say, the air compressor provides air for the whole system as an air source, and the output ends of the input subsystem are respectively communicated with two heating and filtering devices 18, and the two heating and filtering devices 18 are respectively connected. The output end of a heating and filtering device 18 is communicated with the input end of the output subsystem, and the output end of the output subsystem is output to the gas-consuming equipment; the two heating and filtering devices 18 work alternately; through the above structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com