Pump shaft structure

A pump shaft, together technology, applied in the field of pump shaft structure, can solve the problems of unstable transmission torque, affecting the service life of the pump, poor concentricity, etc., to achieve stable and long-lasting operation, increase service life, and shorten the overall length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

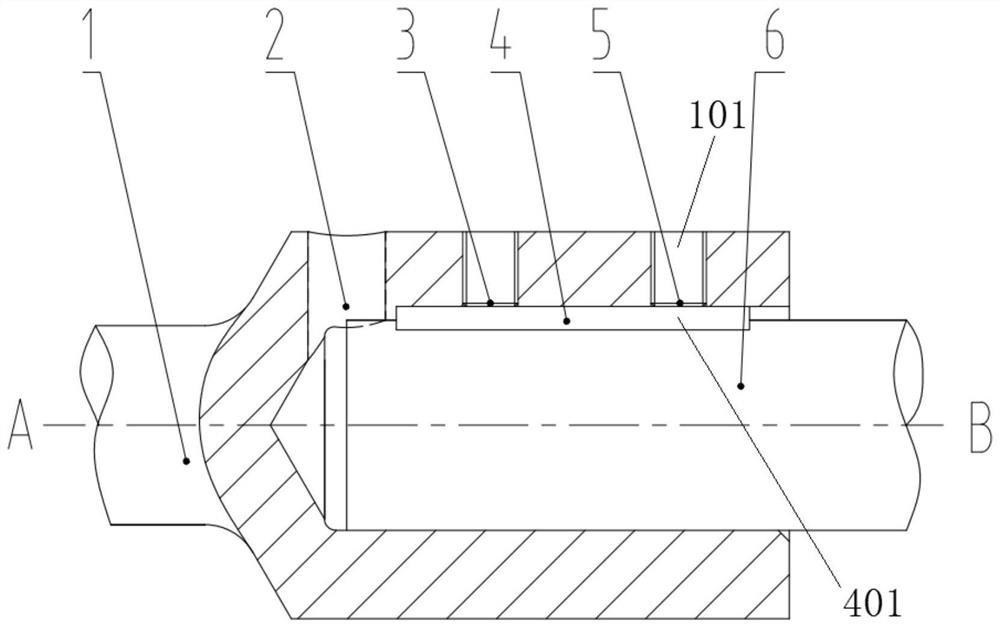

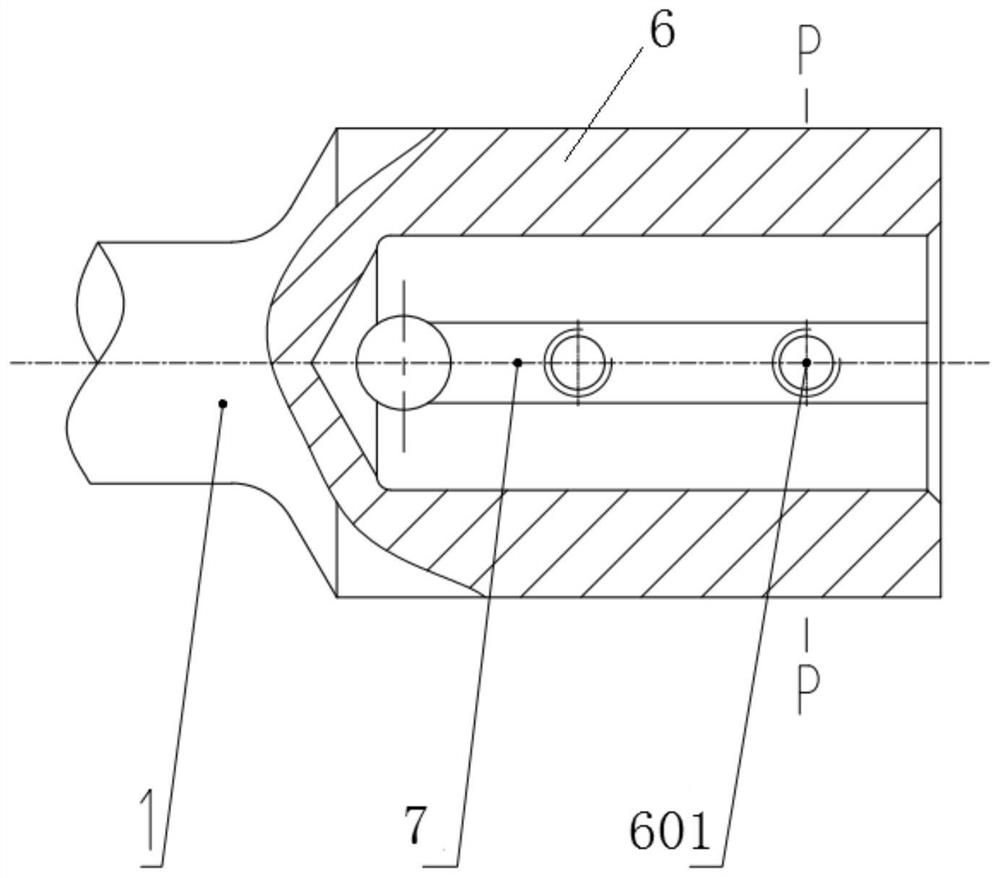

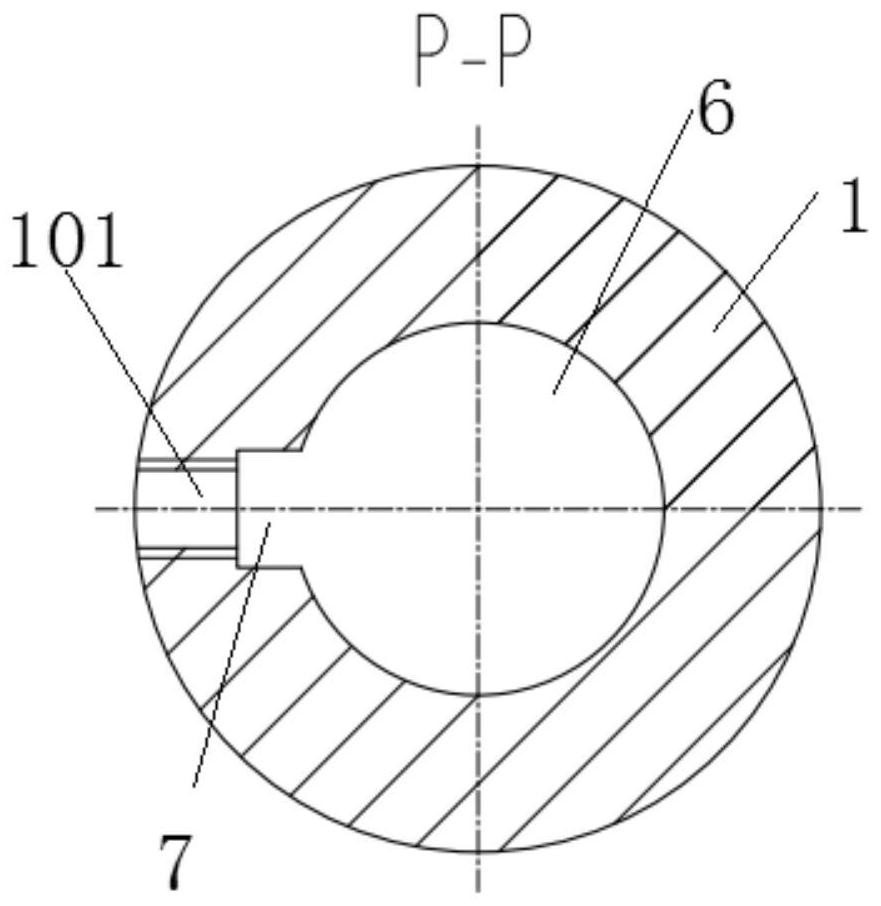

[0020] figure 1 It is a partial cross-sectional view of the front view of the overall structural schematic diagram of the present invention, figure 2 It is a partial cross-sectional view of a top view of the overall structural schematic diagram of the present invention, image 3 for figure 2 The P-P cross-sectional view, as shown in the above figure: the pump shaft structure provided by the present invention, the pump shaft structure includes: the pump shaft 1, the motor shaft 6, the motor shaft 6 is sleeved in the end hole of the pump shaft 1, and the motor shaft 6 is set There is a keyway 7, and a key 4 is arranged in the keyway 7, and the pump shaft 1 and the motor shaft 6 are fixed together through the fixing device passing through the pump shaft 1, the key 4, and the motor shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com