A control device, system, method and device for automatically adjusting the pretightening force of a spindle shaft system

An automatic adjustment and pre-tightening technology, applied in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of inability to automatically adjust the pre-tightening force of the spindle shaft system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

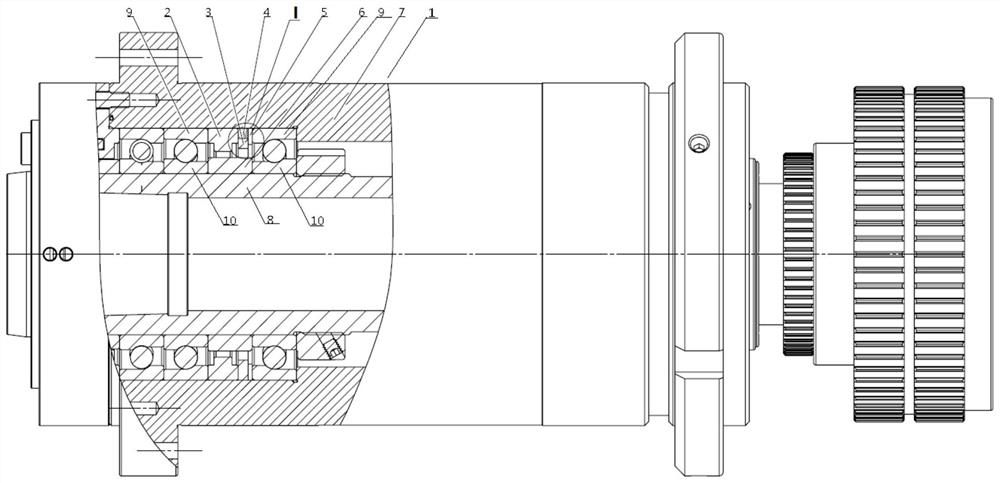

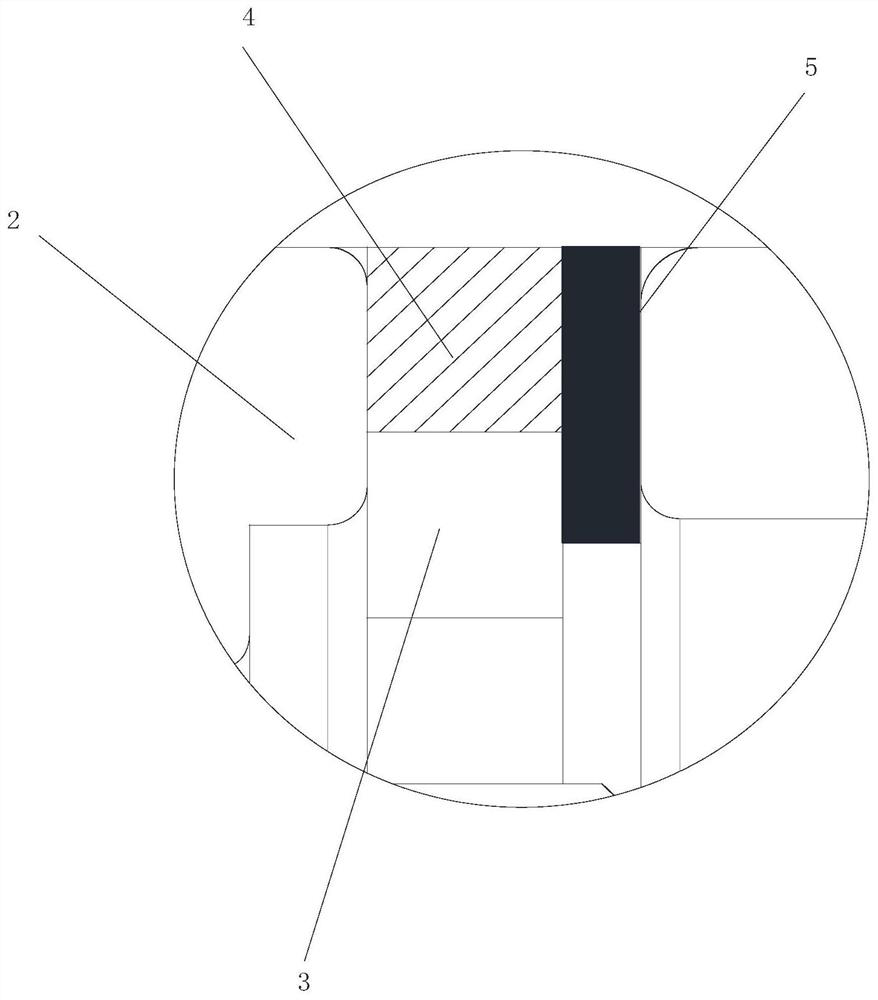

[0034] like figure 1 and 2 As shown, in order to solve the above defects, the present invention provides a control device for automatically adjusting the pretightening force of the main shaft bearing, which includes the shaft core 8 installed on the lathe assembly 1, the body 7 and the main shaft bearing. Wherein, the bearing is sleeved on the outside of the shaft core 8, and the body 7 is sleeved on the outside of the bearing. The bearing generally includes a bearing outer ring 10 and a bearing inner ring 9, since the bearing outer ring 10 is floating relative to the bearing inner ring 9 without preload. Generally speaking, the purpose of changing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com