Automobile processing hole drilling cutter

A technology for drilling tools and automobiles, which is applied in metal processing equipment, drilling/drilling equipment, and drill repairing. Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

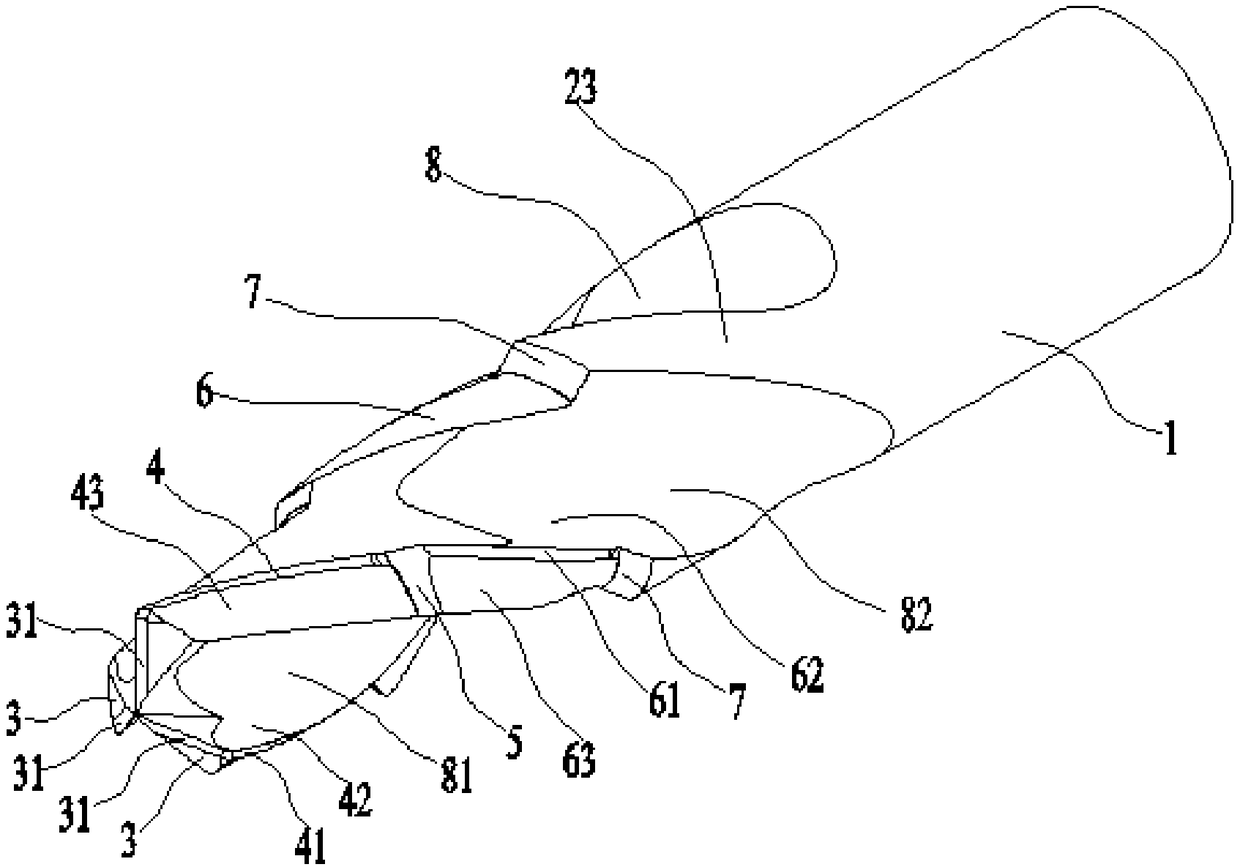

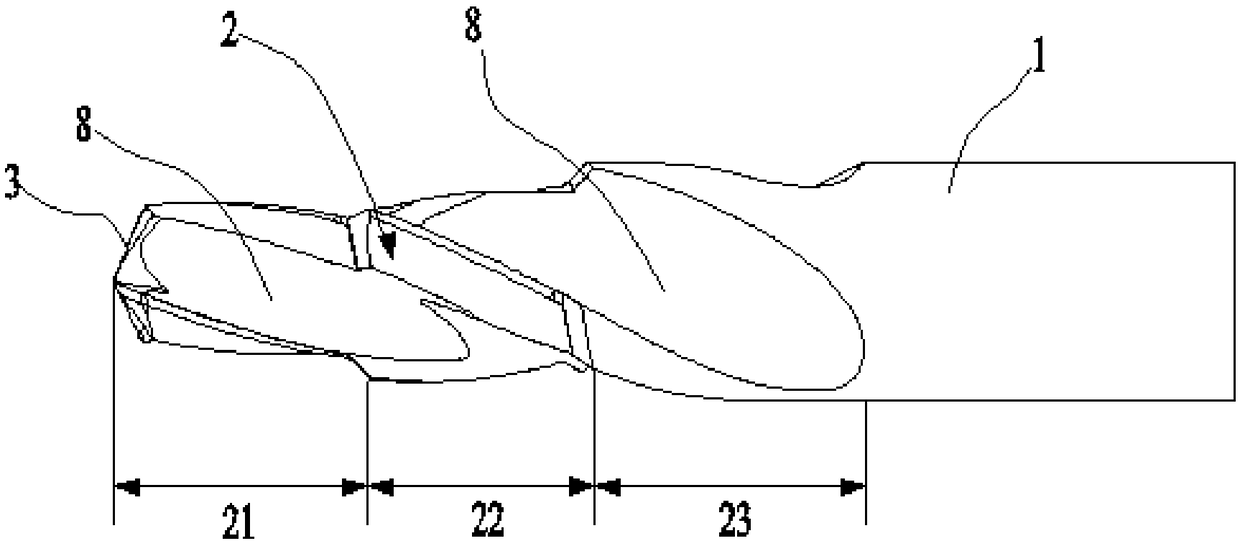

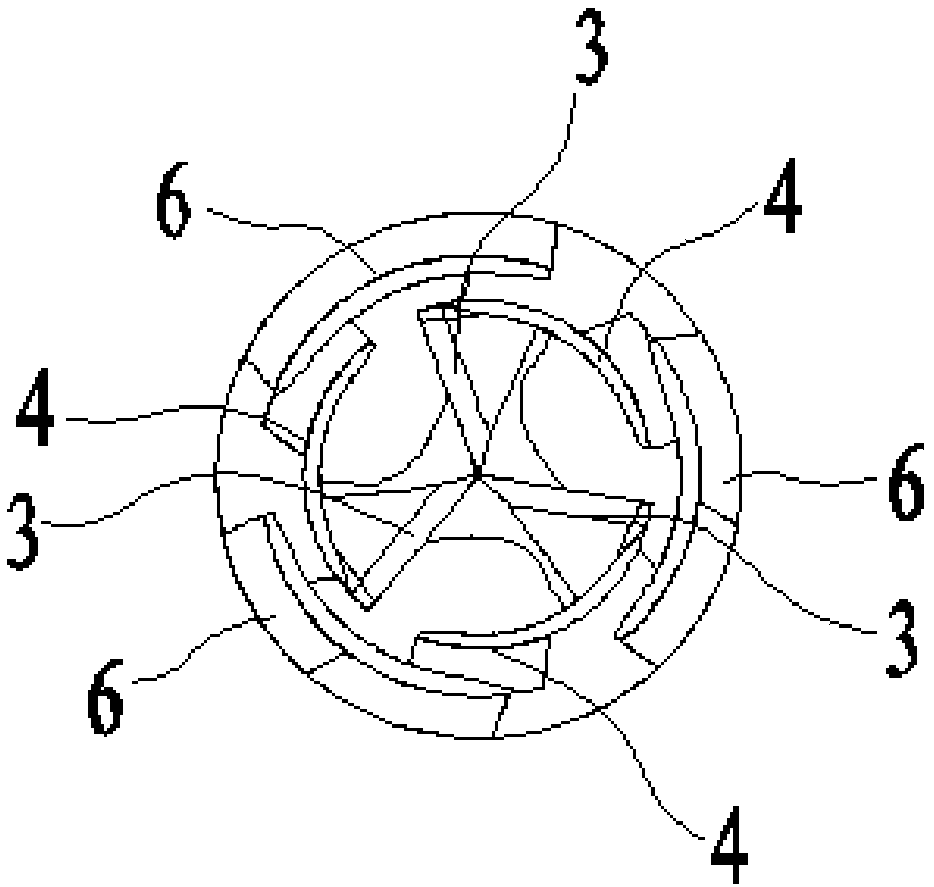

[0016] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

[0017] See attached Figure 1-3 , a drilling tool for automobile processing, comprising a cutter bar 1 and a cutter head formed at one end of the cutter bar 1, the cutter head includes three evenly distributed cutting teeth 2, and the cutting teeth 2 take the longitudinal central axis as a reference axis Turning clockwise, chip removal grooves 8 are provided between adjacent cutting teeth 2 .

[0018] The cutting tooth 2 includes a first reaming section 21 , a second reaming section 22 and a transition section 23 in sequence. The first reaming section 21 includes an end face cutter 3 arranged on the end face of the cutter head, a first reaming cutter 4 extending toward the side of the cutter head, and a first reaming cutter 4 connecting the first reaming cutter 4 and the second reaming section 22. shoulder 5. The second reaming section 22 includes a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com