Arc striking and extinguishing plate installation tool

A technology of arc strike plate and arc plate, applied in the direction of manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve the problems affecting the quality of the frame, time-consuming and laborious installation of arc strike and arc rest plate, unstable installation quality, etc., to achieve Flexible disassembly, reducing welding heat conduction to tooling, avoiding the effect of welding structure and position limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] The installation tooling of the arc strike and rest plate of the present invention can be used for the installation and fixation of the arc strike plate or the arc rest plate. The following only describes the installation of the arc strike plate. different positions.

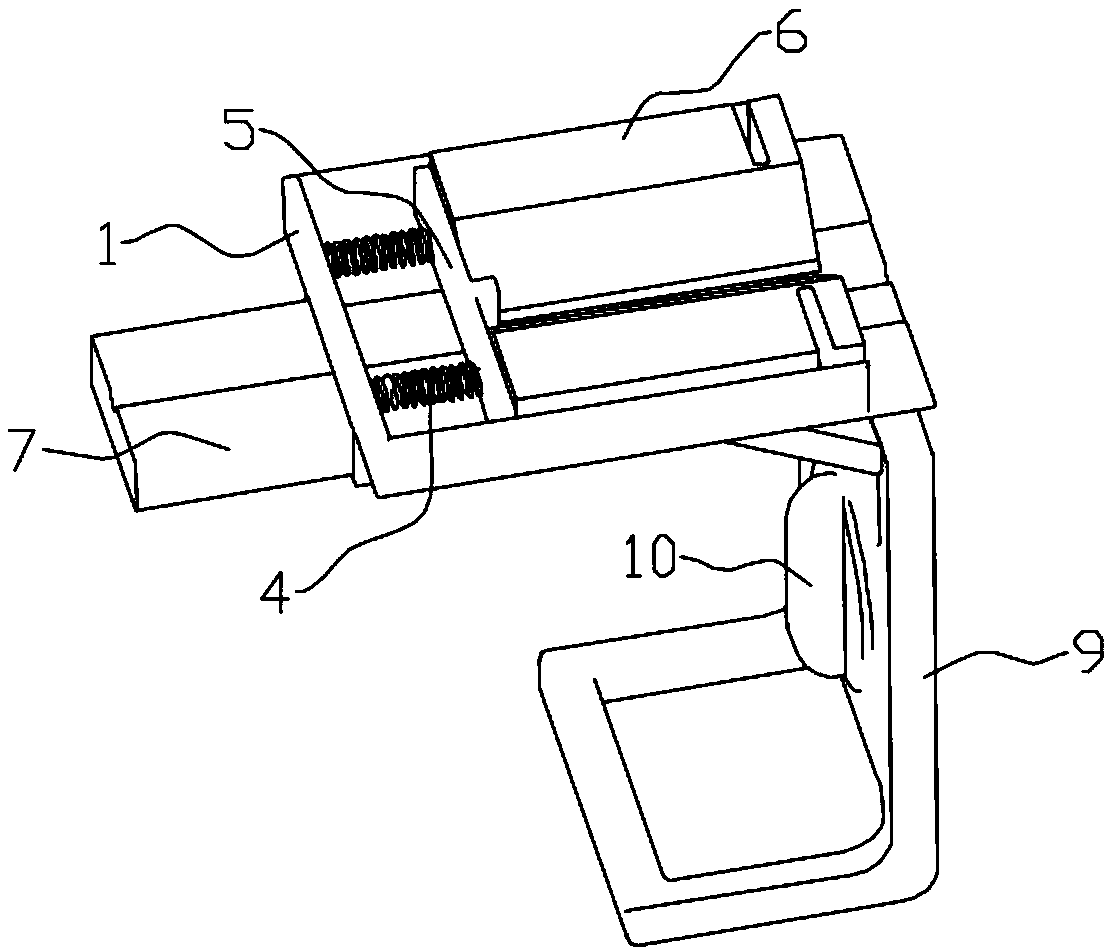

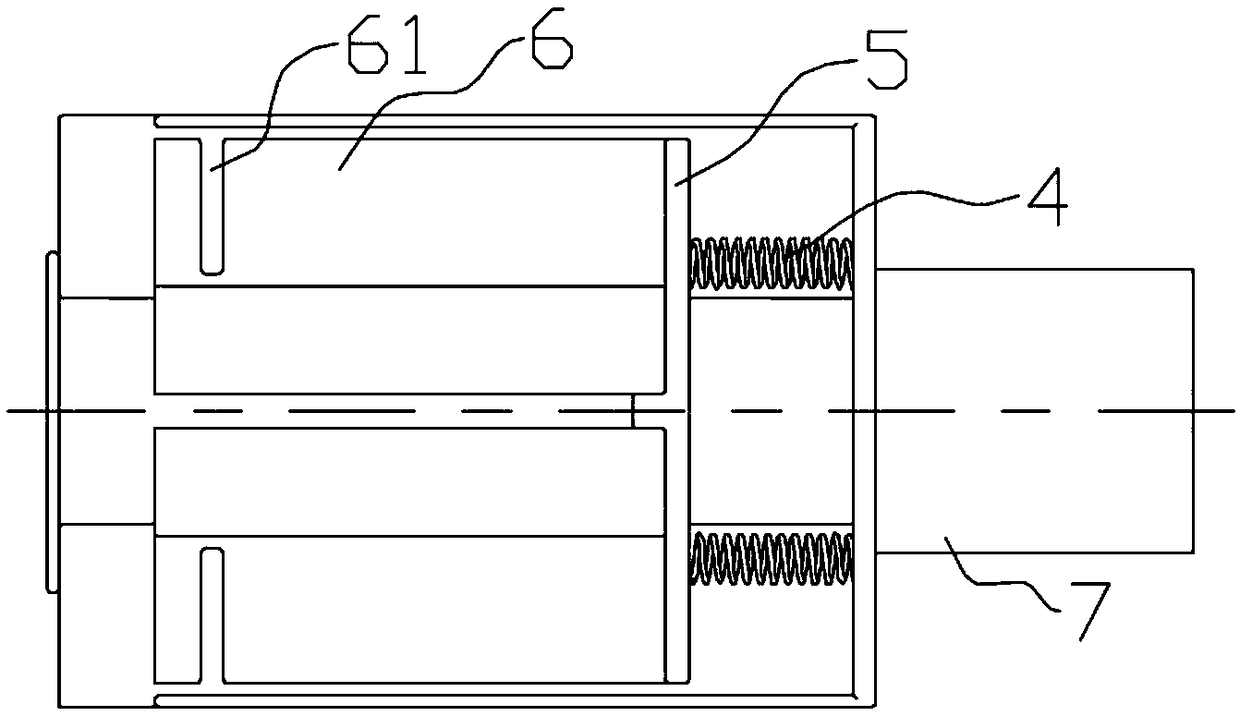

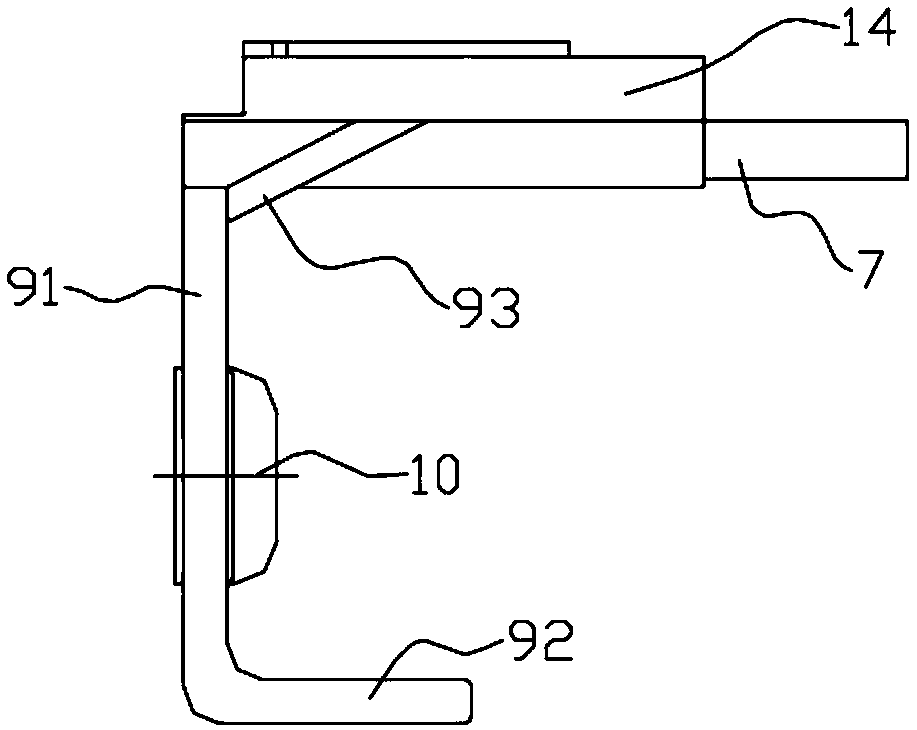

[0031] see Figure 1-8 , the positioning part 1 (tooling body) of the arc strike plate installation tool of the present invention is mainly composed of plates, including a U-shaped plate 11 and an arc strike plate bottom plate 12 fixed on the top of the U-shaped plate 11, three parts of the arc strike plate bottom plate 12 Two edges are respectively provided with an end plate 13 and two oppositely arranged side plates 14, and the arc running plate bottom plate 12, the end plate 13 and the side plate 14 together form an arc running plate mounting groove 2 for accommodating and positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com