A welding and clamping device for multi-bent pipe fittings and brackets

A technology of welding clamps and pipe bends, which is applied in welding equipment, auxiliary devices, welding accessories, etc., can solve the problems of inaccurate alignment and welding, inaccurate alignment, prone to rolling, shaking and movement, etc., and achieve stable position , Precise positioning and locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: A welding and clamping device for multi-bending pipe fittings and brackets.

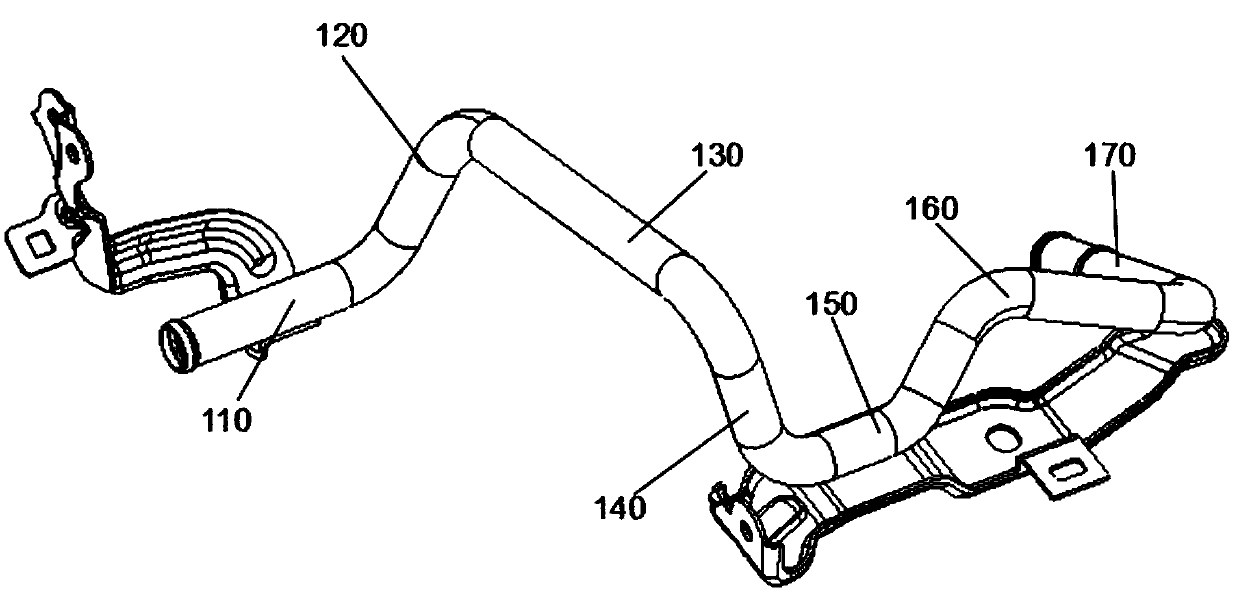

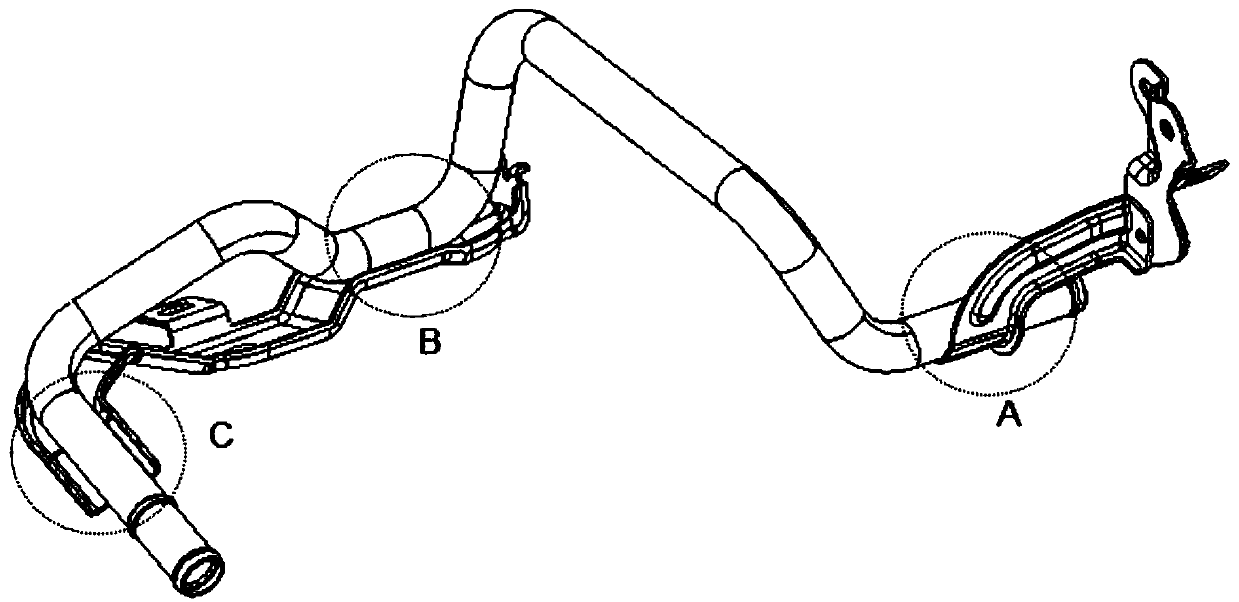

[0036] refer to Figure 1 to Figure 14 As shown, a welding clamping device for multi-bending pipe fittings and brackets, including:

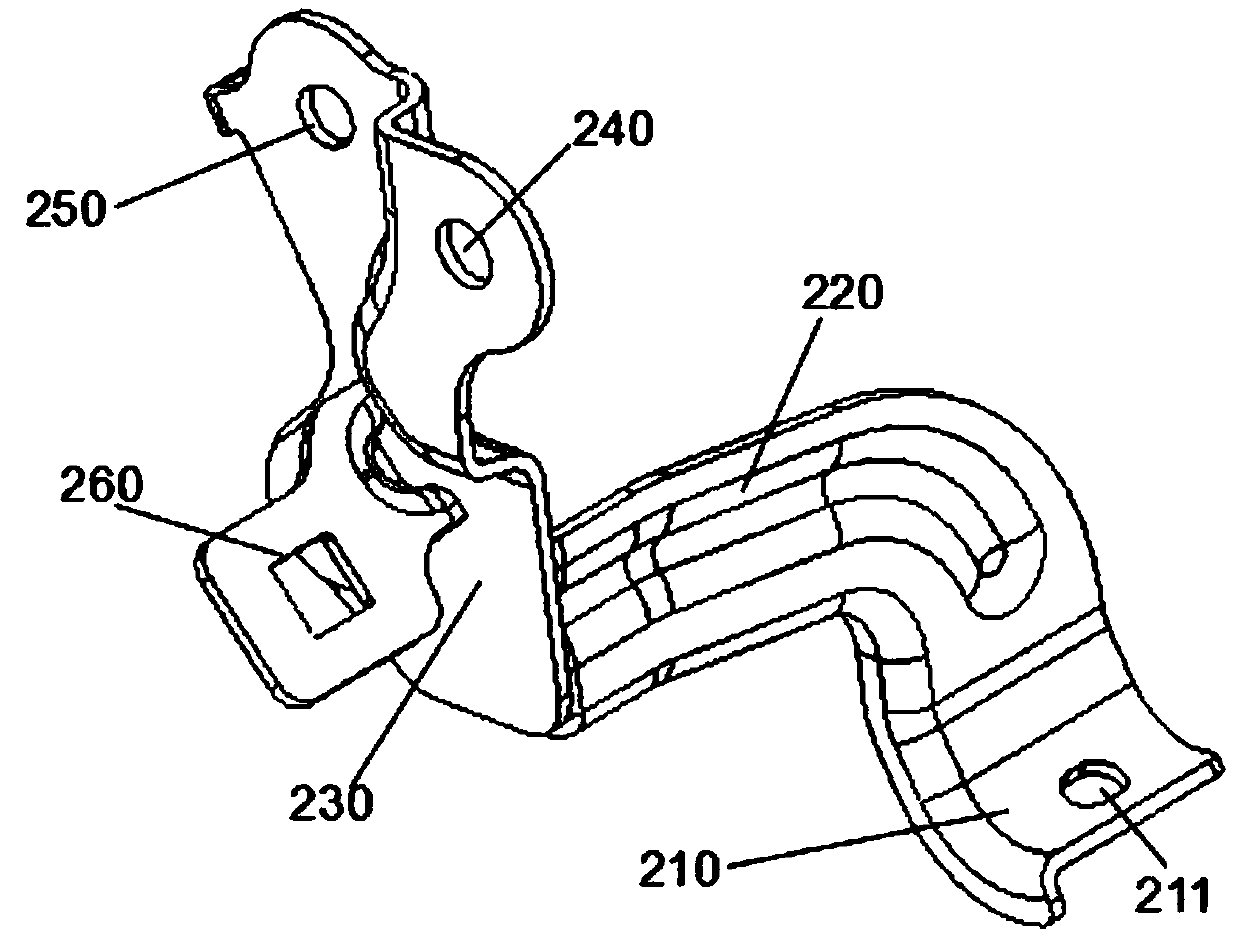

[0037] Fixture bottom plate 1; the first elbow positioning seat 11 fixed on the middle part of the fixture bottom plate 1 by screws, the rear end of the left side, the top and the front end of the right side of the first elbow positioning seat 11 are respectively provided with oil circuit cooling In the pipe 100, the left connecting elbow portion 120, the middle horizontal straight pipe portion 130, and the middle connecting elbow portion 140 match the positioning groove, and the first quick clip 12 is installed on the right side wall of the first elbow positioning seat 11, so that The first quick clamp 12 and the positioning groove on the first elbow positioning seat 11 constitute the first clamping position for the oil cooling pipe 100, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com