Anti-friction driven linear positioning cylinder based on screw locking and its control method

A positioning cylinder, driving type technology, applied in the direction of fluid pressure actuators, mechanical equipment, etc., can solve the problems of high processing cost, low positioning accuracy, complex structure assembly, etc., to solve the problem of reduced sealing, high positioning accuracy, structural The effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

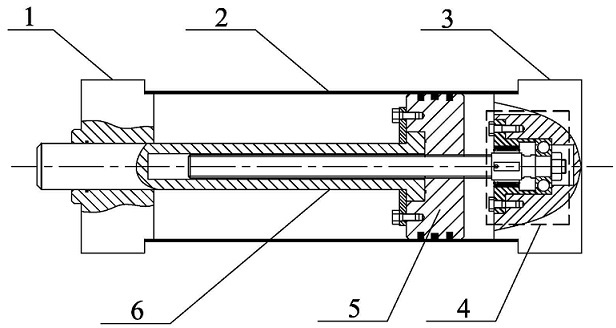

[0032] Specific implementation mode one: combine Figure 1~Figure 13 To illustrate this embodiment, this embodiment provides a specific implementation of a screw locking type anti-friction driven linear positioning cylinder, and its specific implementation is expressed as follows:

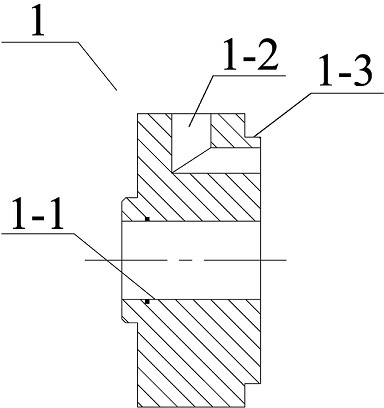

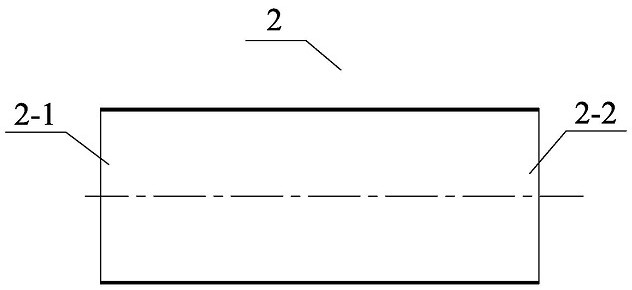

[0033]The linear positioning cylinder based on screw locking type anti-friction driven linear positioning cylinder is composed of end cover I1, cylinder barrel 2, end cover II3, screw locking mechanism 4, piston mechanism 5 and piston rod 6, wherein the The two ends of the cylinder 2 are tightly connected with the end cover I1 and the end cover II3 respectively, and the screw locking mechanism 4 is installed on the end cover II3, and after passing through the piston mechanism 5, it is threadedly connected with the piston rod 6, and the piston The mechanism 5 and the piston rod 6 are locked. The piston mechanism 5 is installed in the cylinder 2, slides axially in the cylinder 2 with the gas conversi...

specific Embodiment approach 2

[0041] Specific implementation mode 2: This implementation mode provides a specific implementation mode of a control method based on screw locking type anti-friction driven linear positioning cylinder, and its specific implementation mode is expressed as follows:

[0042] Two sets of ultrasonic electric signals are passed into the electrode plate I4-2 and the electrode plate II4-3 respectively, and the electrical signals are transmitted to the piezoelectric stretchable sheet 4-8 through the electrode ball head I4-9 and the electrode ball head II4-10 respectively. The expansion and contraction direction of the piezoelectric expansion sheet 4-8 is parallel to the axis of the screw rod 4-1, and the control mode of the piezoelectric expansion sheet 4-8 includes an in-phase driving mode and an out-of-phase driving mode;

[0043] The in-phase driving mode is to pass ultrasonic electric signals with the same characteristic parameters to the electrode plate I4-2 and the electrode plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com