Telescopic type wheel transmission structure for PECVD reaction area

A transmission structure, telescopic technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low transmission efficiency, complicated operation, affecting the utilization rate of the whole line equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

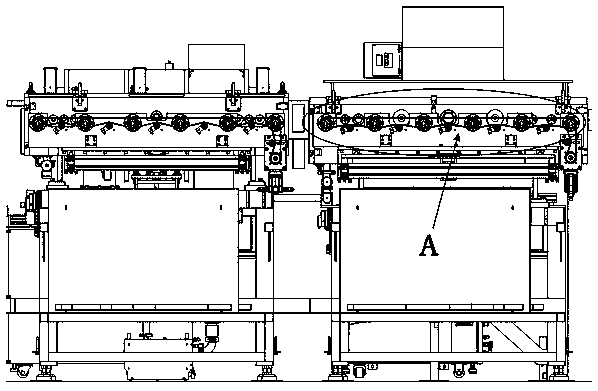

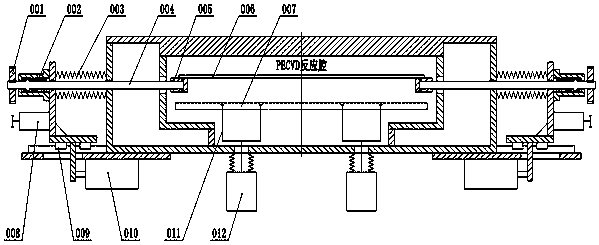

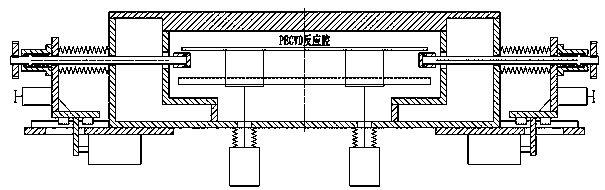

[0032] This application discloses a telescopic roller transmission structure for PECVD equipment. In PECVD equipment, the telescopic roller transmission structure is used for the transmission of workpieces to the reaction area. The linear feeding method of the roller transmission improves the transmission efficiency. The setting can be retracted after completion, avoiding the impact of the rollers on the PECVD reaction zone. Therefore, this kind of telescopic roller transmission structure effectively improves the efficiency of workpiece transmission in PECVD equipment, solves the problems of slow beat and complex structure of PECVD equipment, and improves the productivity of the entire equipment.

[0033] The telescopic roller transmission structure provided by the present application will be introduced and illustrated in detail below through specific embodiments.

[0034] figure 1 It is one of the internal structural diagrams of the telescopic roller transmission structure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com