Horizontal type disassembling and assembling cylinder machine for vertical column jack

A jack and column technology, applied in the field of hydraulic cylinders, can solve the problems of high processing precision, high cost, complex assembly, etc., and achieve the effects of adjustable swing amplitude, flexible disassembly force, and flexible disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

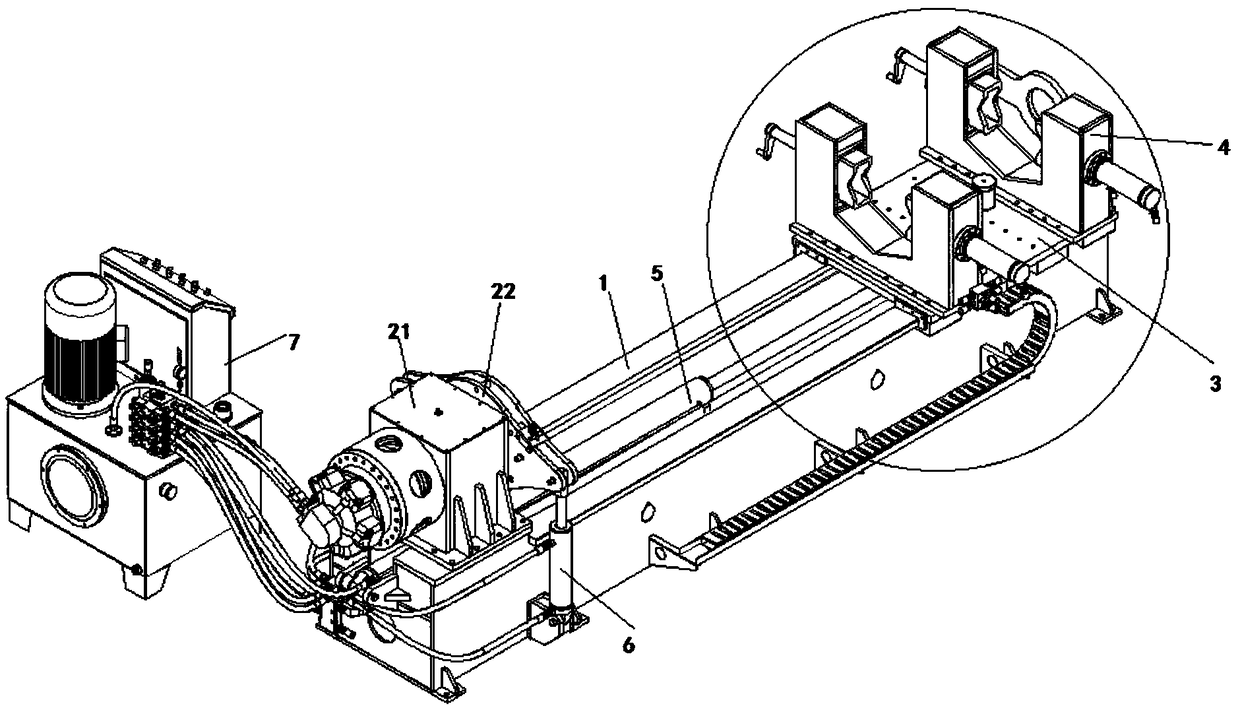

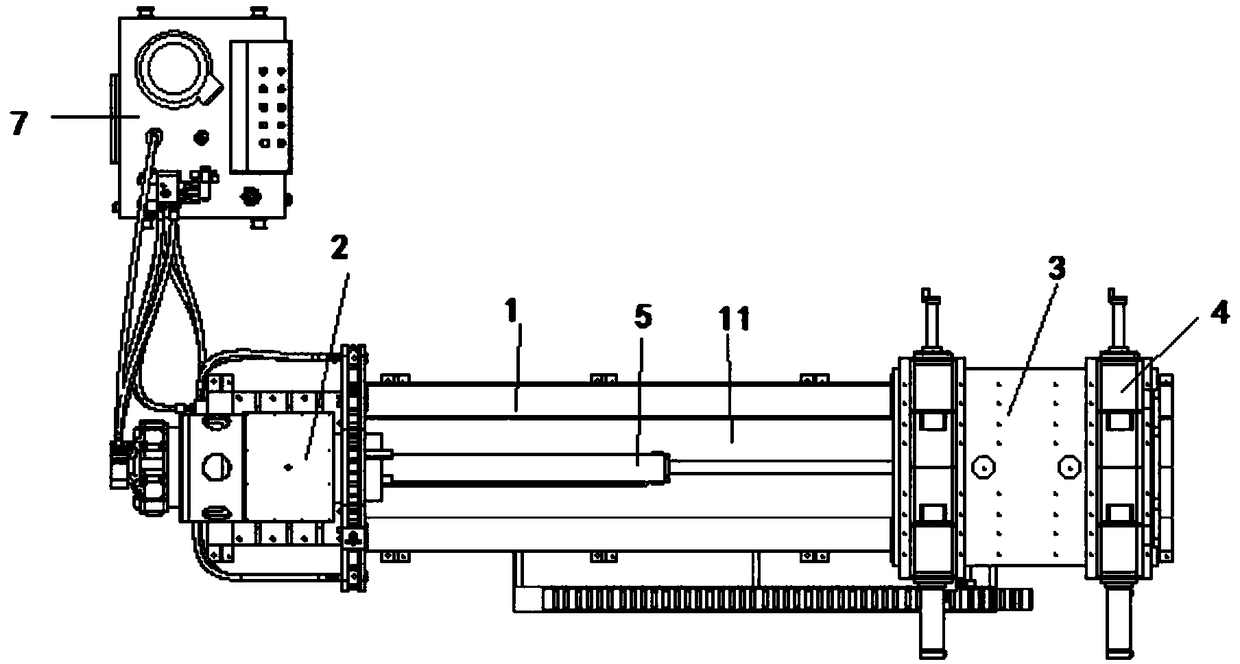

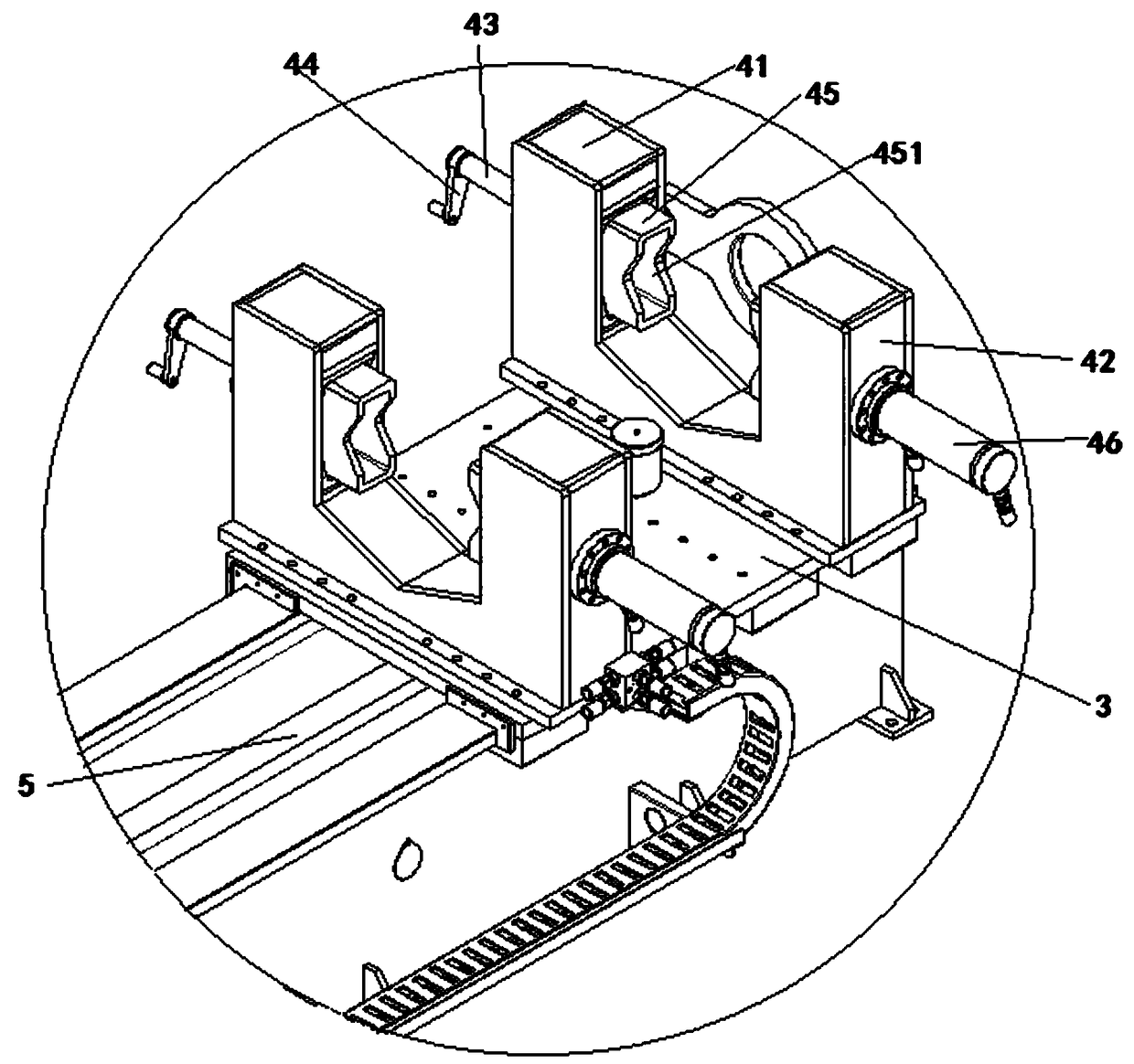

[0020] A horizontal column jack dismantling cylinder machine, such as figure 1 and figure 2 As shown, it includes a frame 1 and a transmission box assembly 2 installed and fixed on one end of the frame 1. The other end of the frame 1 is slidably installed with a fixed frame 3, and the two ends of the surface of the fixed frame 3 are mounted and fixed with two oppositely arranged clamping parts. Agency 4;

[0021] The frame 1 is a strip support plate structure, the middle part of the surface of the frame 1 is provided with a strip groove 11, one end side wall of the strip groove 11 is fixed with a positioning oil cylinder 5, and the power output end of the positioning oil cylinder 5 is installed and fixed on On the fixed frame 3, the fixed frame 3 is driven to slide along the frame 1 through the positioning oil cylinder 5, and then the distance between the transmission box assembly 2 and the clamping mechanism 4 is changed, so that the column jacks to be disassembled with dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com