Efficient polishing equipment

A high-efficiency and equipment technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of increasing production costs, increasing the labor intensity of grinding workers, affecting the grinding quality, etc., to reduce labor intensity and avoid errors. , to ensure the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

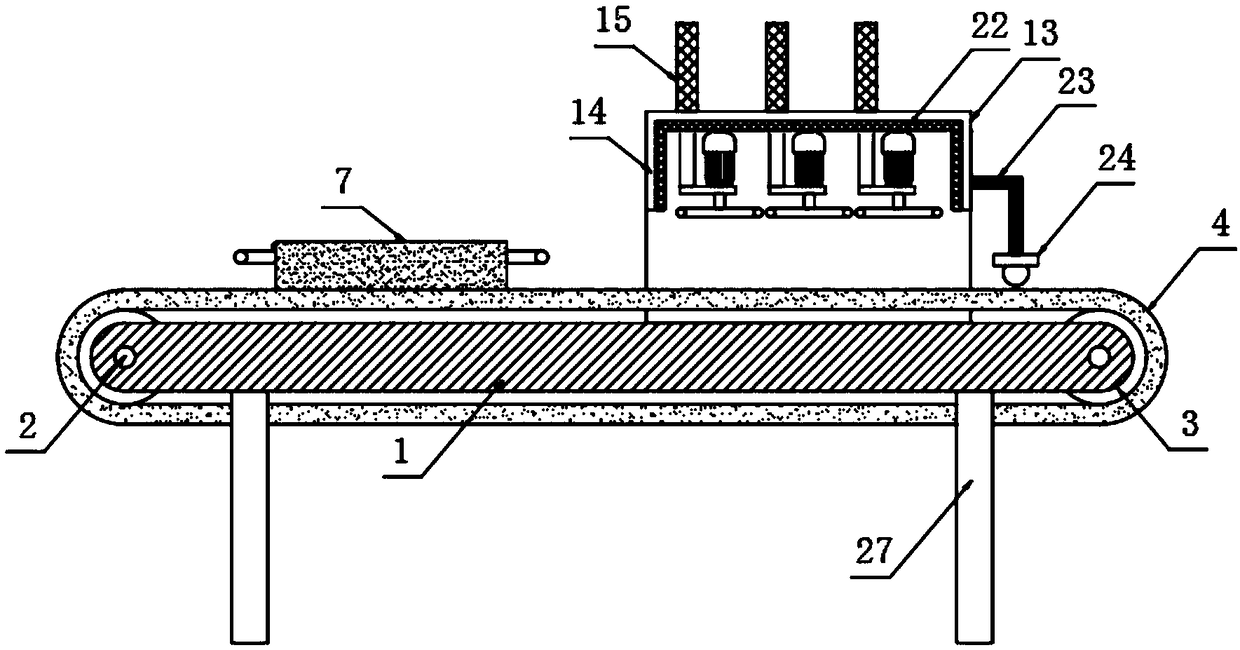

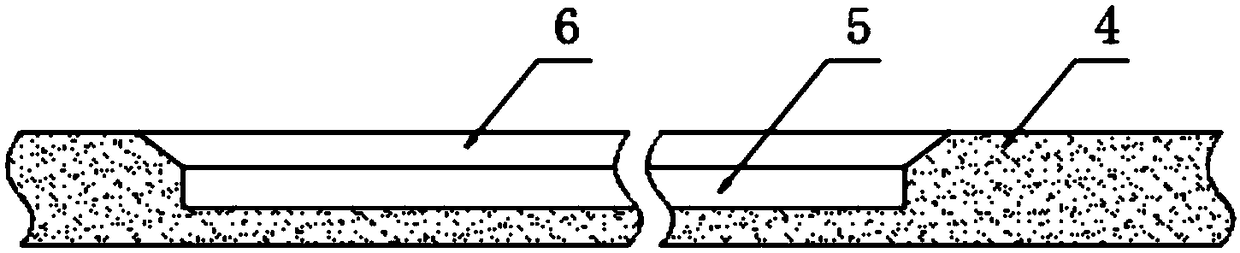

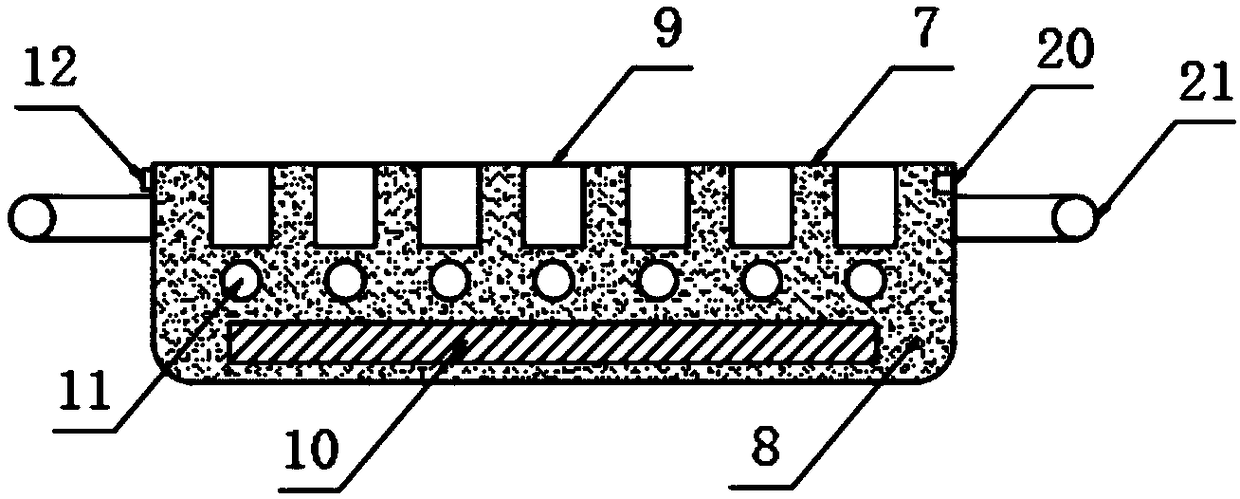

[0026] The present invention provides such as Figure 1-5 The high-efficiency grinding equipment shown includes a bed side plate 1, a drive shaft 2 is arranged between the bed side plates 1, and a rotating roller 3 is sleeved on the outside of the drive shaft 2, and the rotating roller 3. A conveyor belt 4 is sleeved on the outer side. The conveyor belt 4 is provided with a fixing groove 5 and a guide groove 6. The guide groove 6 is arranged on the top of the fixing groove 5. The inside of the fixing groove 5 is provided with a bearing mechanism 7. The carrying mechanism 7 includes a mold main body 8, the top of the mold main body 8 is provided with an accommodation groove 9, the inside of the mold main body 8 is provided with a battery 10 and a first electromagnet 11, and a side of the mold main body 8 is provided with a push switch 12. A grinding mechanism 13 is fixed on the top of the bed side plate 1 .

[0027] It can be seen from the above-mentioned embodiments that the ...

Embodiment 2

[0029] Further, in the above-mentioned embodiment 1, the fixing groove 5 is matched with the bearing mechanism 7, and the cross section of the guide groove 6 is set as an inverted equilateral trapezoid, so as to play a guiding role, so that the bearing mechanism 7 can be placed more easily In the fixed slot 5;

[0030] The first electromagnet 11 is arranged on the top of the battery 10, and the first electromagnet 11 is arranged on the bottom of the receiving tank 9;

[0031] The other side of the mold main body 8 is provided with a charging socket 20 for charging the battery 10, and both sides of the mold main body 8 are fixed with handles 21, so that the carrying mechanism 7 can be taken more conveniently;

[0032] The grinding mechanism 13 includes a cover body 14, the top of the cover body 14 is fixedly provided with a cylinder 15, the bottom end of the cylinder 15 is fixedly arranged on a mounting plate 16, and the top of the mounting plate 16 is provided with a variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com