Improved food cutting equipment

A technology of food cutting and equipment, applied in metal processing and other directions, can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

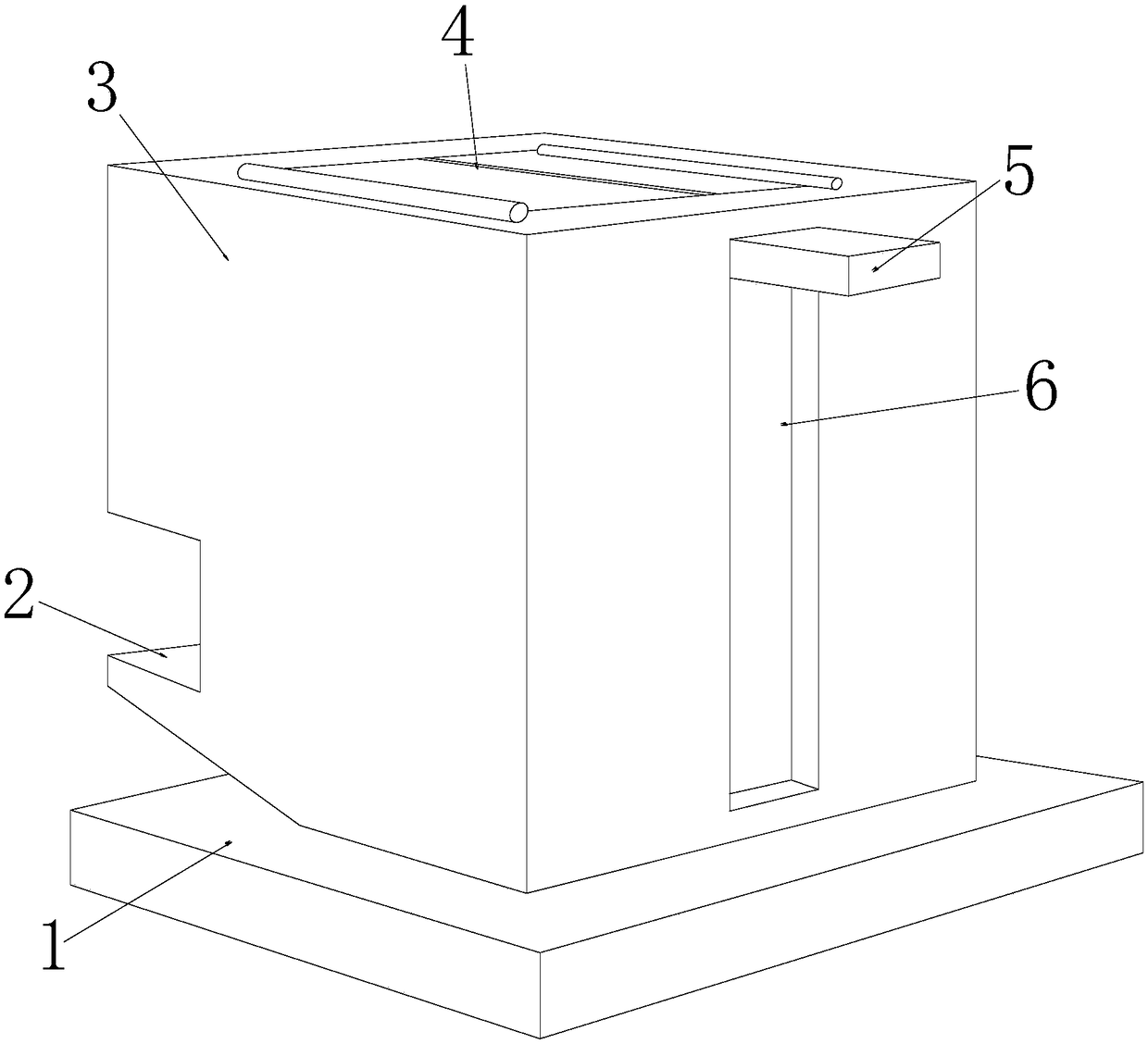

[0024] see Figure 1-Figure 4 , the present invention provides improved food cutting equipment, the structure of which includes a fixed installation base 1, an output end 2 after processing, a cutting operation box 3, an extrusion inlet end 4, a control pressing plate 5, and a pressing slide rail 6;

[0025]The bottom end of the cutting operation box 3 is horizontally installed on the top of the fixed installation base 1, the processed output end 2 is embedded in the side end of the cutting operation box 3, and the extrusion inlet port 4 is installed on the cutting operation box 3 away from the fixed installation base 1. One end is connected with a hinge, the control pressing plate 5 is embedded in the pressing slide rail 6 for mechanical connection, and the pressing slide rail 6 is installed in the cutting operation box 3 at the end away from the processed output end 2;

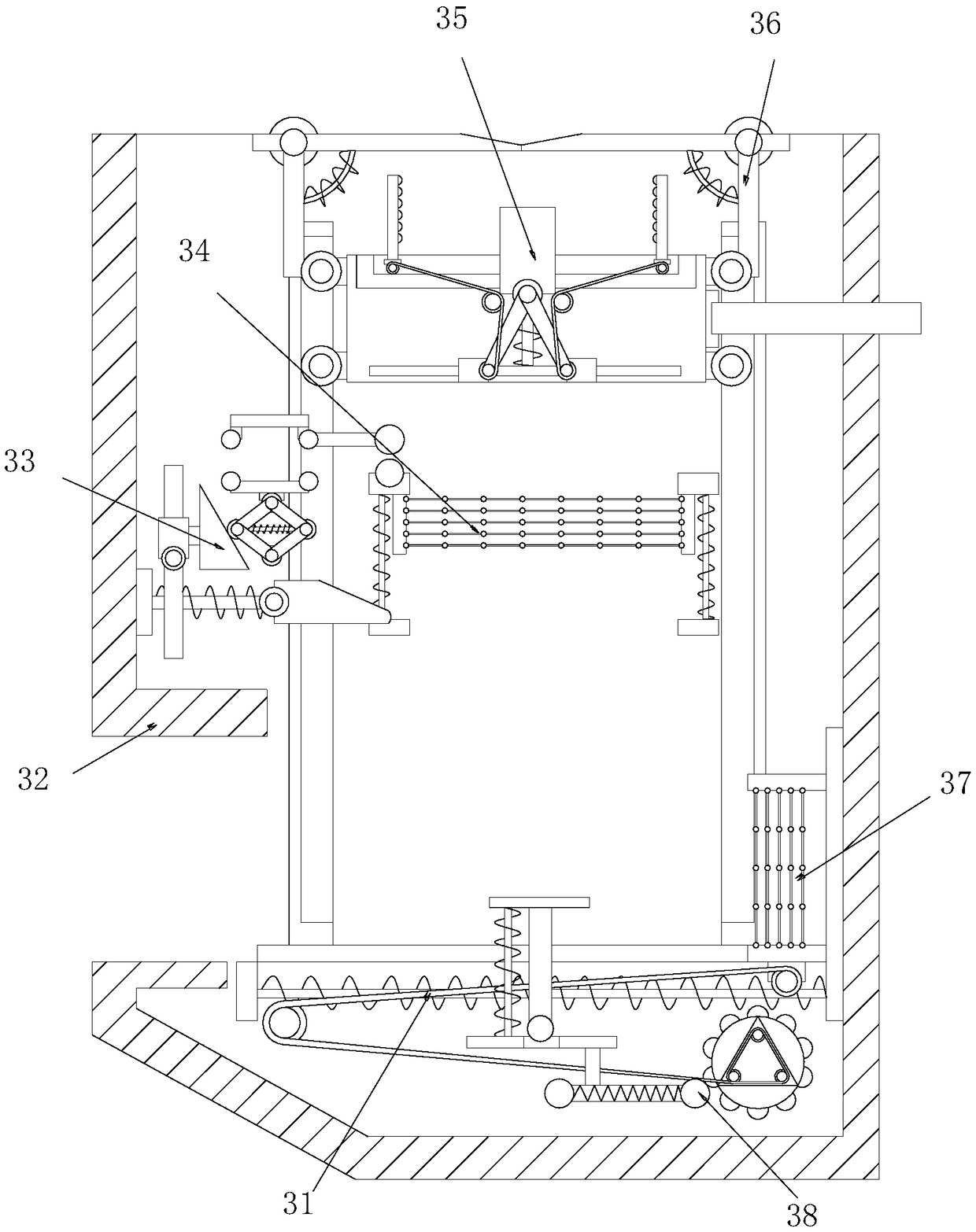

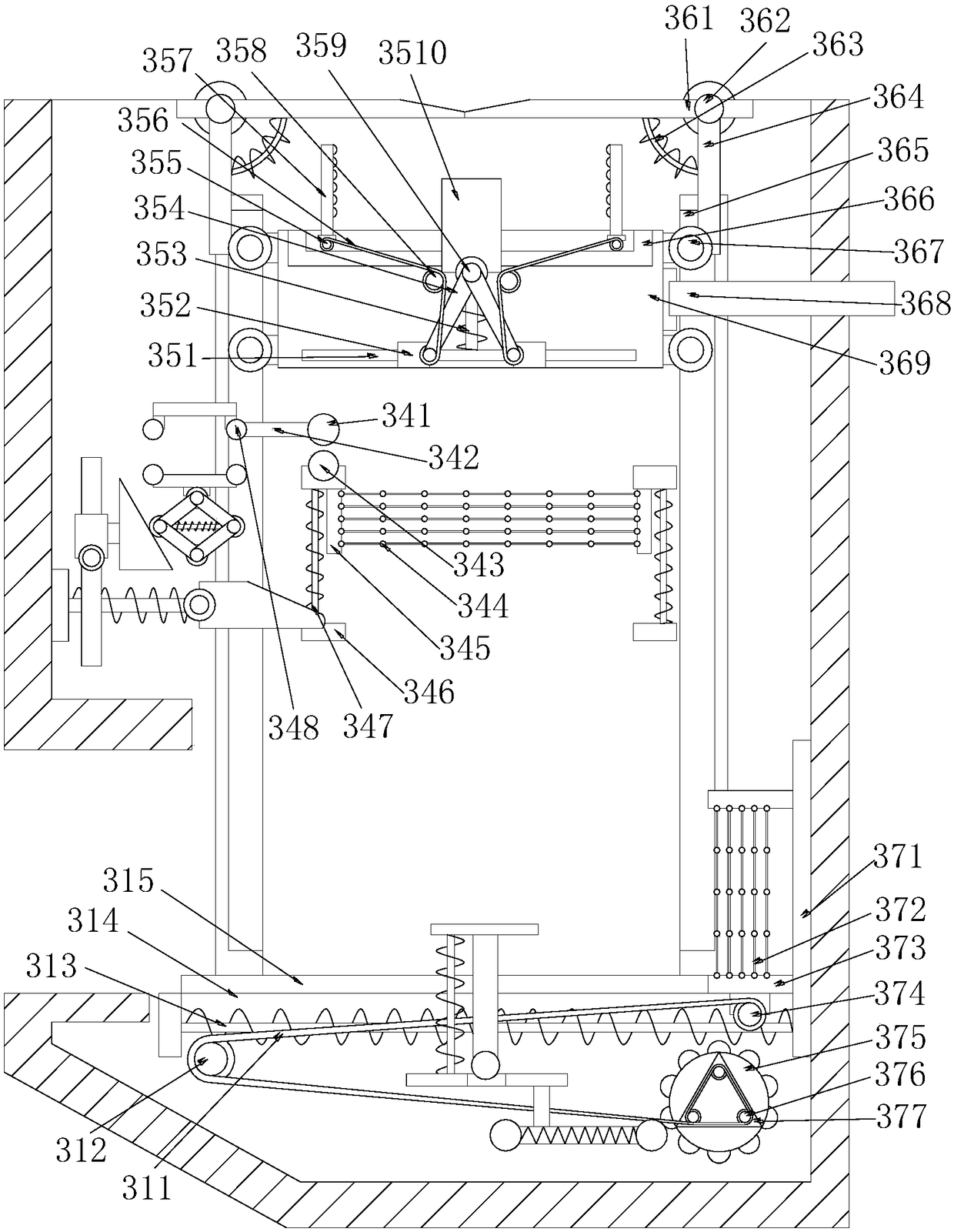

[0026] The cutting operation box 3 includes a squeeze return device 31, a protective shell 32, a squeeze ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap