Correction tape shell formed through DIY splicing and combining

A correction tape and casing technology, applied in printing, erasers, office supplies, etc., can solve the problems of single style, non-foldable, low interest, etc., achieve small space occupation, save transportation costs, fast and convenient operation and interesting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example one

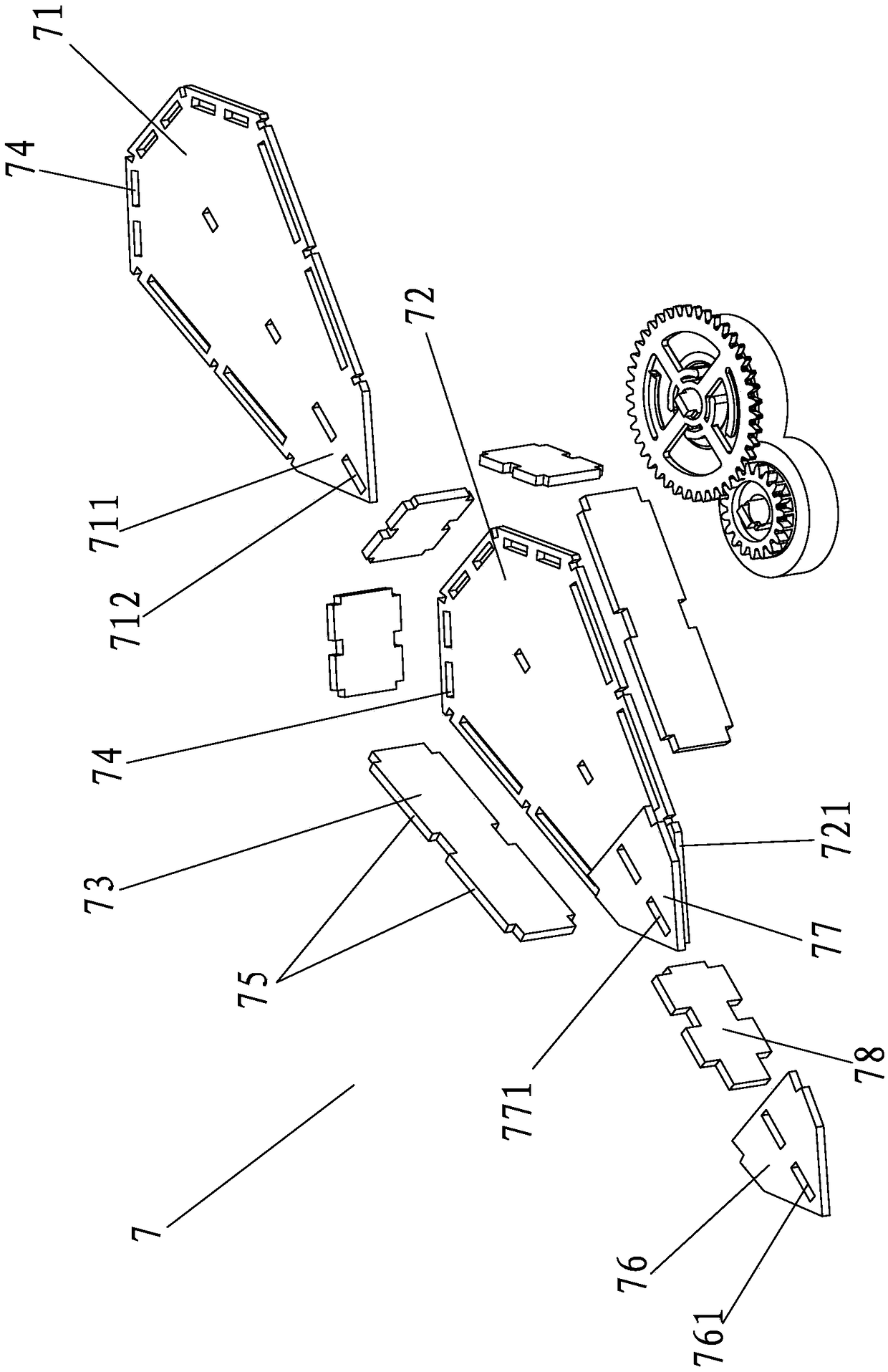

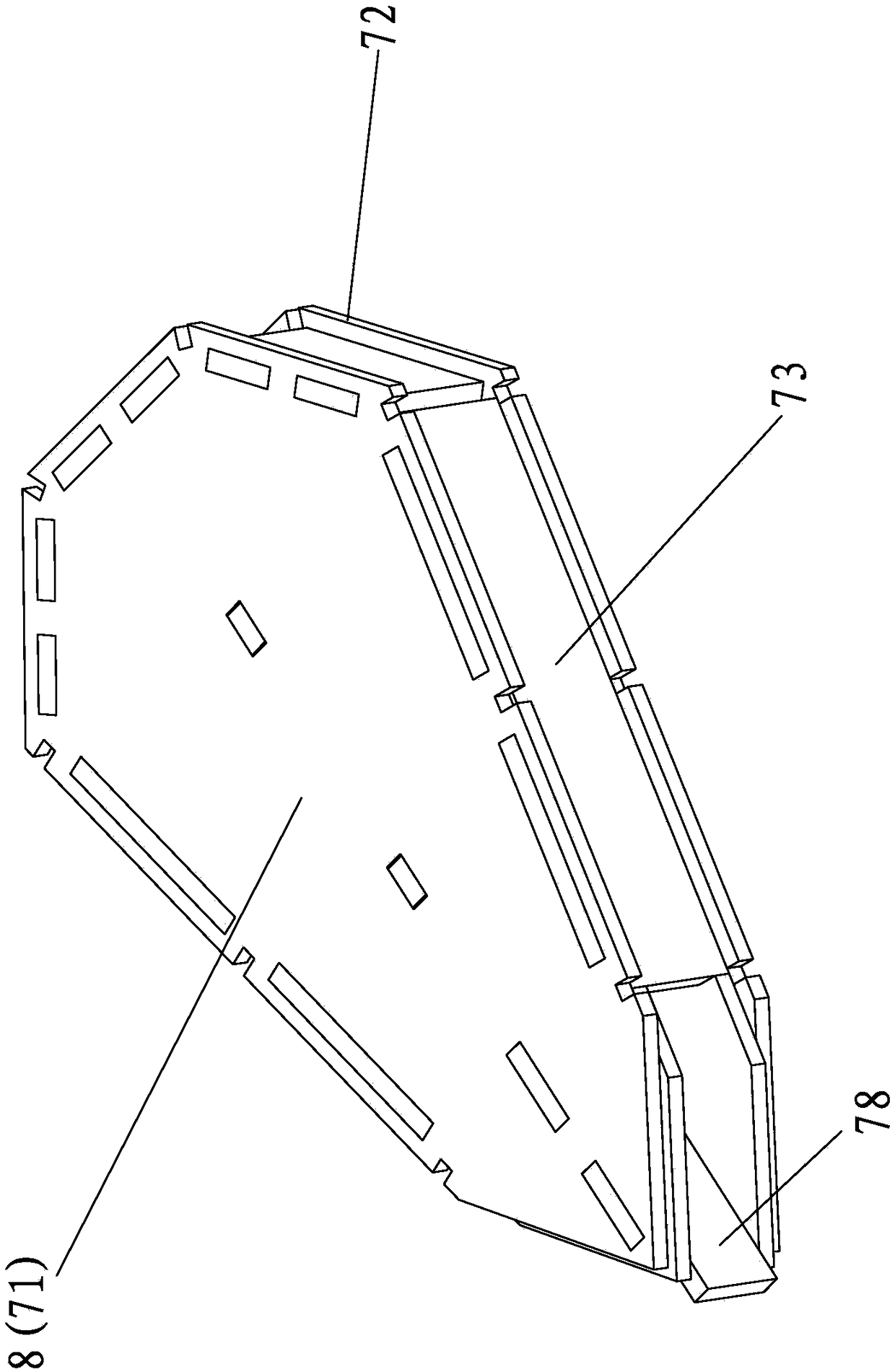

[0025] The present invention is a DIY assembled and combined correction tape shell, such as figure 1 with figure 2 As shown, it includes a plurality of pieces 7 of different shapes assembled by DIY to form a casing 8 with a set correction tape shape. Among the plural pieces 7 are assembled to form a nozzle end piece of the nozzle. In this embodiment, the plural pieces 7 are in the shape of a flat plate.

[0026] The plurality of blocks 7 includes a top plate 71, a bottom plate 72 and a plurality of side plates 73. The top plate 71 and the bottom plate 72 have the same shape and size, and they are arranged up and down oppositely. The side plate 73 is enclosed and spliced between the top plate 71 and the bottom plate 72. The outer periphery of the top plate 71 and the bottom plate 72 are respectively provided with a plurality of slots 74, and the side plate 73 is provided with a tongue 75 correspondingly. The tongue 75 is matched with the socket 74, and the ...

Example Embodiment

[0033] Example two

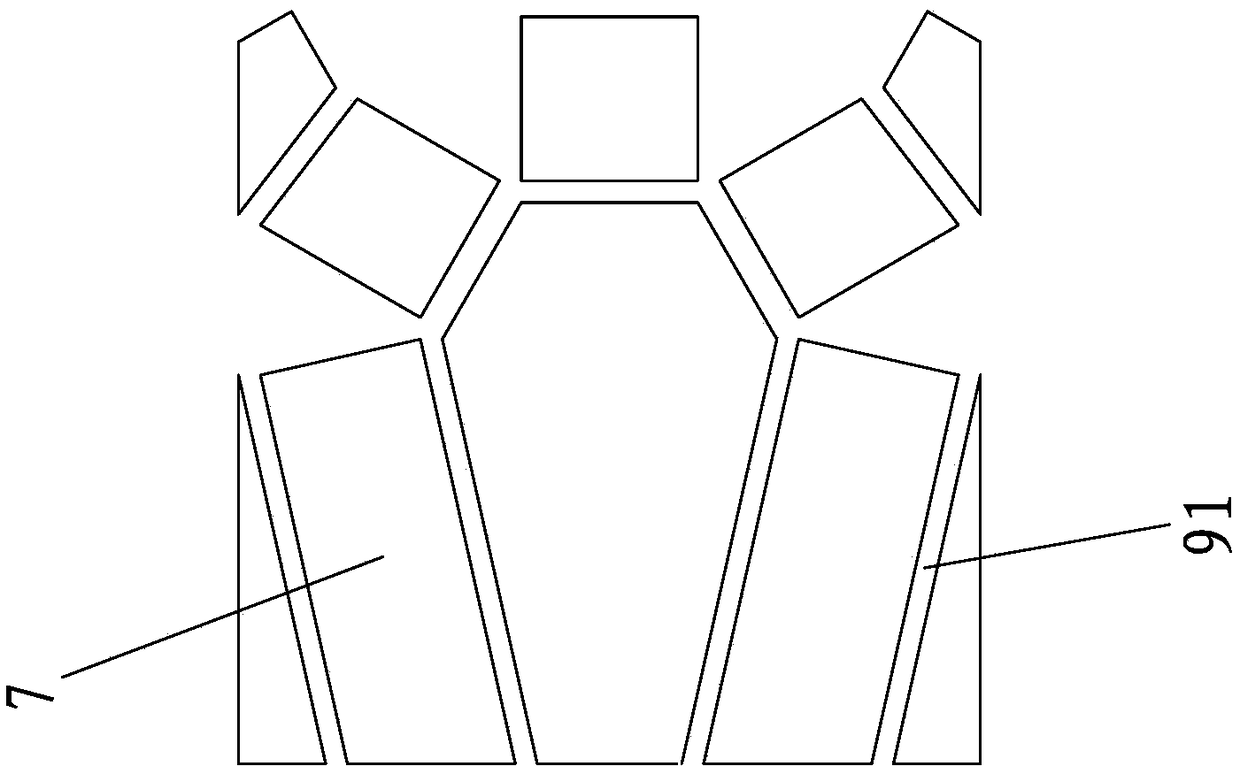

[0034] The present invention is a DIY assembled and combined correction tape shell, such as Figure 3-Figure 4 As shown, a plurality of pieces 7 of different shapes are assembled and assembled by DIY to form a casing with a set correction tape shape, and the plurality of pieces 7 have a plurality of pieces assembled to form the spout end piece of the spout.

[0035] A plurality of pieces 7 are respectively pasted on the set positions of the substrate layer 9 to form a body to be folded. The adjacent pieces 7 are pasted at intervals to form a guiding crease 91. The substrate layer 9 is formed by Made of materials with flexibility and bending resistance, the to-be-folded body is folded and assembled by DIY to form a casing with a shape of the correction belt.

[0036] The base material layer 9 is adhesive paper with adhesiveness on at least one side, and a plurality of the pieces 7 are respectively pasted on the adhesive side of the adhesive paper. Preferably, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap