Cap-screwing chuck

A technology for capping claw heads and clamping jaws, applied in the field of clamping jaws, can solve the problems of unfavorable automatic production, laborious and laborious work, low work efficiency, etc., and achieve the effects of ensuring work efficiency, reliable clamping and accurate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

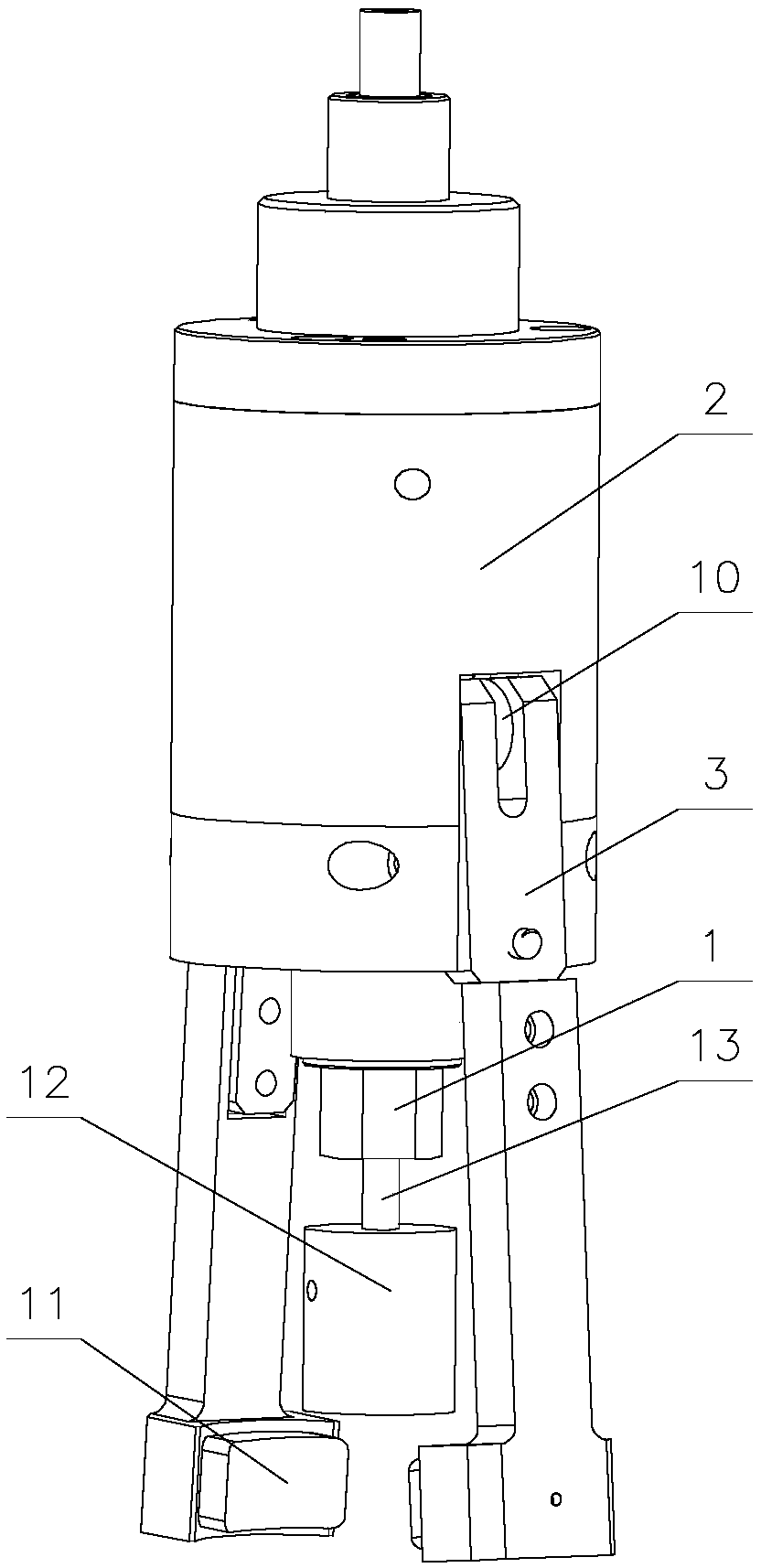

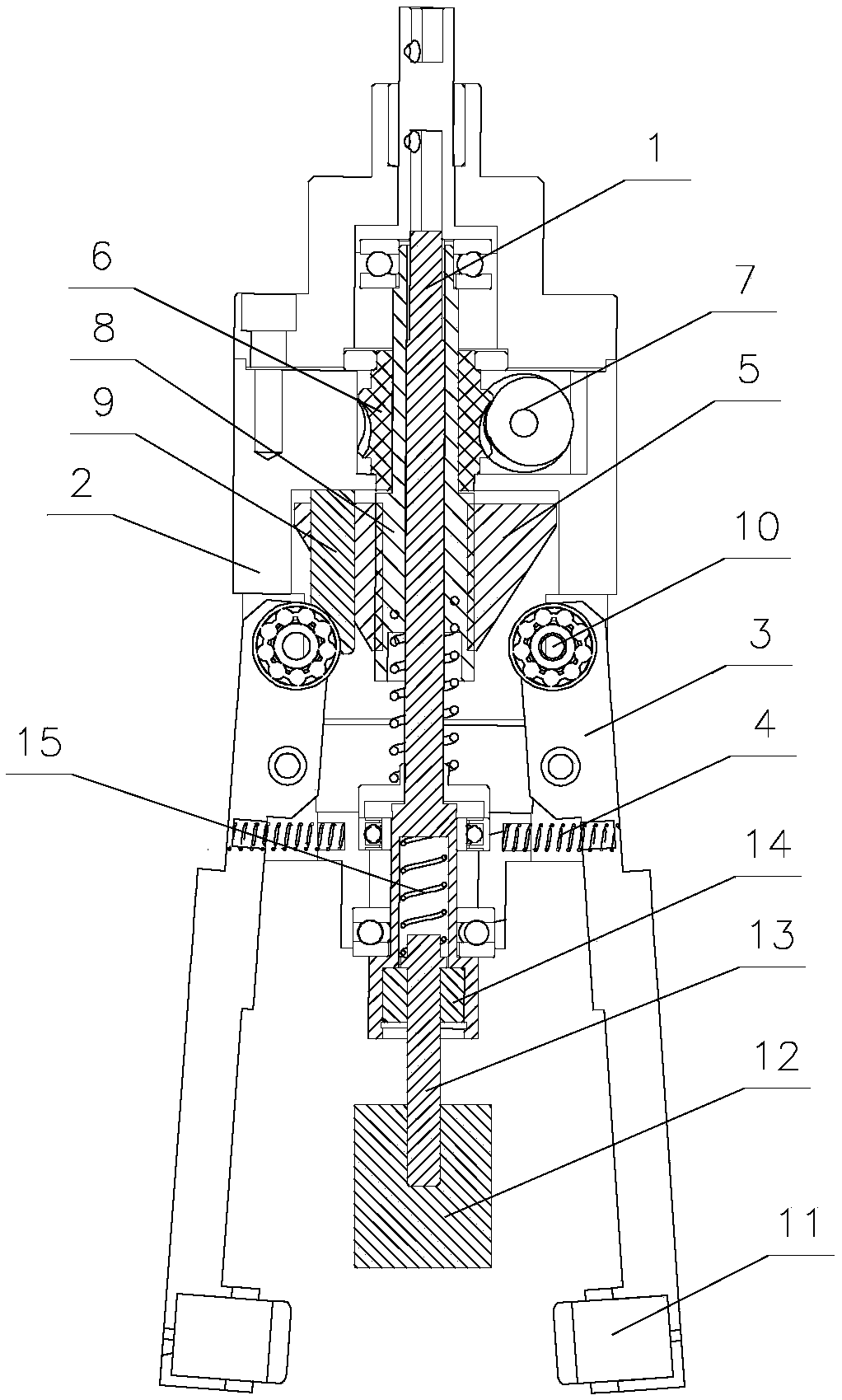

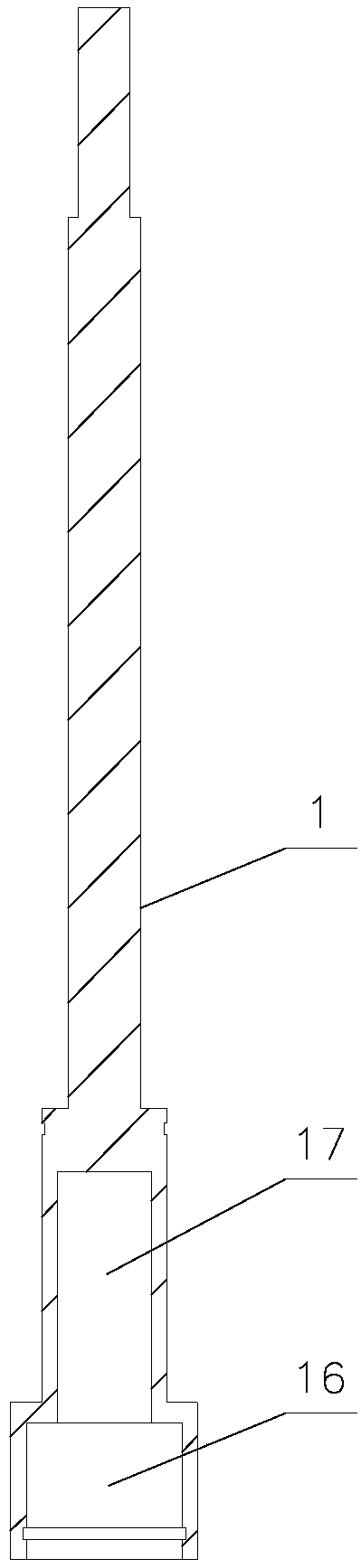

[0019] The present invention will now be described in detail with reference to the accompanying drawings. This figure is a simplified schematic diagram, and only illustrates the basic structure of the present invention in a schematic manner, so it only shows the structure related to the present invention.

[0020] like Figure 1-5 As shown, a capping claw head of the present invention includes a main shaft 1, an adjustment assembly and a clamping jaw assembly arranged on the main shaft 1, the clamping jaw assembly includes a sleeve 2 and two clamping rods 3, the sleeve The sleeve 2 is sleeved on the main shaft 1 and the main shaft 1 is rotatably connected with the main shaft 1 through a bearing. The sleeve 2 is provided with a driving device that drives the sleeve 2 to rotate along the axis. On both sides of the sleeve 2, the rod bodies of the two clamping rods 3 are hinged with the side walls of the sleeve 2, the axes of the hinge points of the two clamping rods 3 and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com