Trackless trolley for transferring reinforcing mesh sheets of rock-fill dam panels and construction method

A technology of steel mesh and trackless trolley, which is applied in the direction of dams, barrages, weirs, etc., can solve the problems of high cost of installation and removal of tracks, time-consuming and labor-intensive adjustment of trolley height, and sloshing of mesh, so as to achieve simple and fast construction , Easy to install and remove, easy to transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

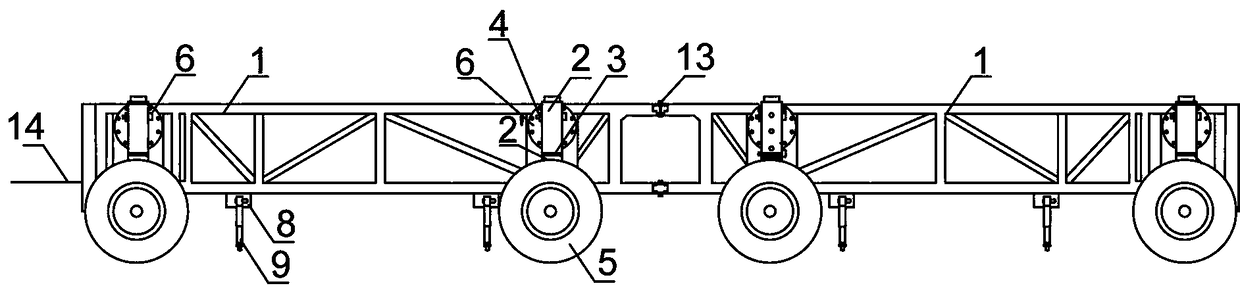

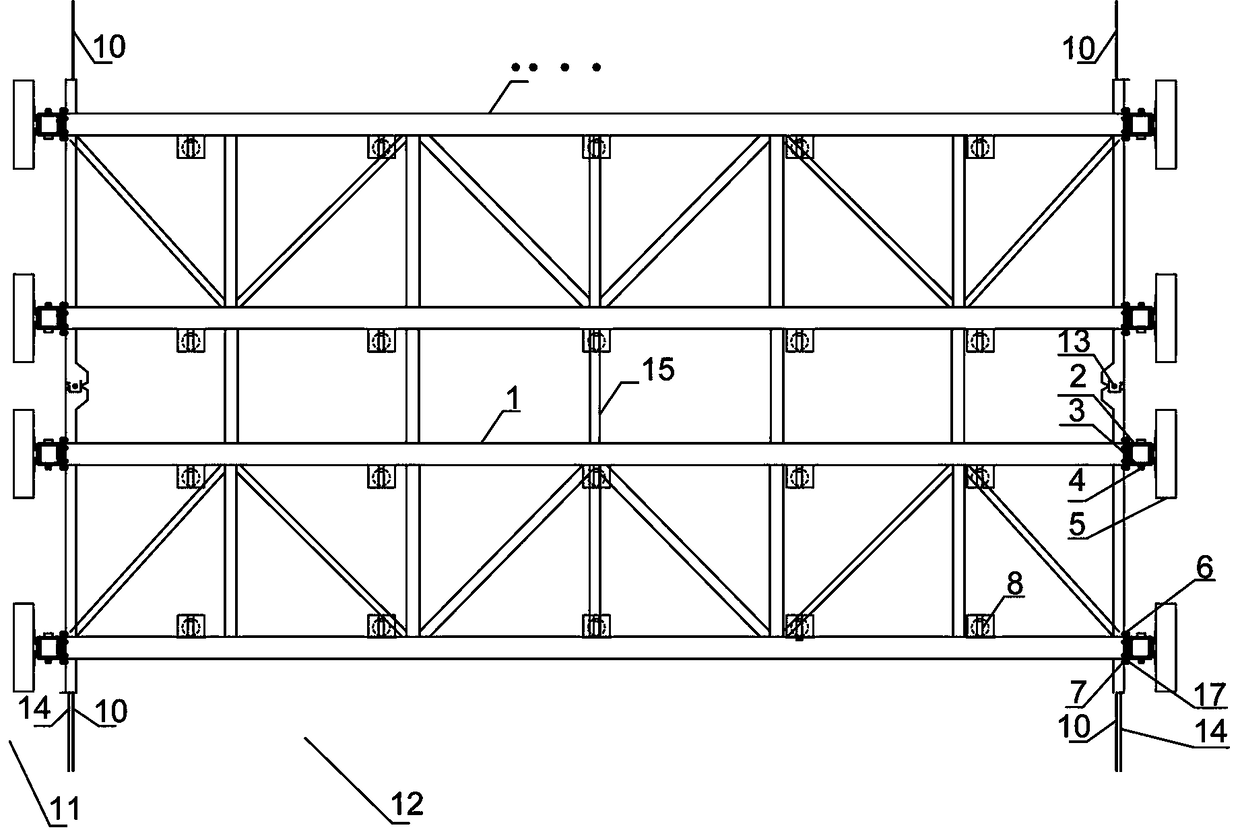

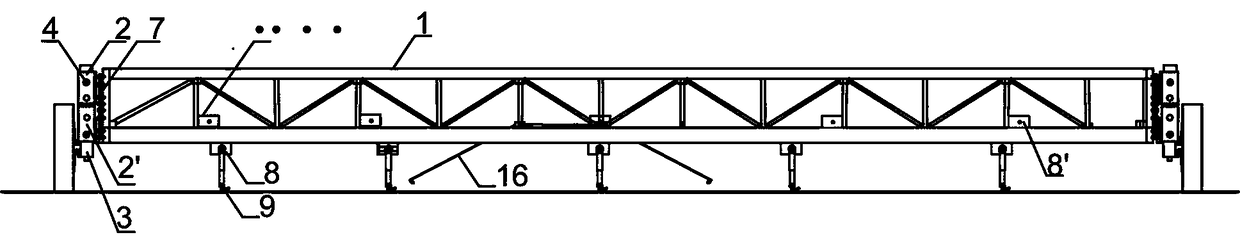

[0041] Such as Figure 1~9 Among them, there is a trackless trolley for transferring steel mesh panels of rockfill dam panels. A plurality of walking tire devices 5 are provided at the bottom of the trolley frame, and the walking tire devices 5 are connected to the trolley frame through a lifting mechanism;

[0042] A plurality of liftable hooks 9 are also provided at the bottom of the trolley frame. With this structure, the trackless trolley of the present invention can individually adjust the height of the walking tire device 5 and the height of the suspended steel mesh according to the different working conditions of various panel thicknesses in the construction of the panel first and second blocks. To overcome the problems in the prior art.

[0043] In a preferred solution, the lifting mechanism is a screw jack, one end of the screw jack is fixedly connected to the shaft of the walking tire device 5, and the other end of the screw jack is fixedly connected to the trolley frame...

Embodiment 2

[0054] A construction method of a trackless trolley that uses the above-mentioned transfer of steel mesh panels of the rockfill dam faceplate includes the following steps:

[0055] s1. First hoist the first steel truss 1 to the dam surface, adjust the construction direction and fix the position, and then hoist the second steel truss 1'to the dam surface. After adjusting the construction direction, use the hinge pins 13 to connect to each other, and then use The connecting steel member 15 is fixedly connected. The two sides of the trolley frame are connected with the hoist wire rope 14 of the hoist on the top of the dam; the walking tire device 5 is located outside the joint 10 of the current cast block.

[0056] s2. When the walking tire device 5 of the trackless trolley transfers the steel mesh on the post-cast block 12, lift the trolley frame. In the preferred solution, the hydraulic jack in the liftable hook 9 is used to lift the trolley against the ground Or use a car crane to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com