Passive-type low-energy-consumption steel composite fireproof door

A low-energy, passive technology, applied in the field of entry doors, can solve the problems of unseen comprehensive performance entry doors, damage to technical performance, singleness, etc., and achieve the effects of good anti-theft performance, good blocking of heat conduction, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is given in conjunction with the accompanying drawings, and the detailed description of the specific embodiment of the present invention that needs to be explained is to facilitate a comprehensive understanding of the technical solution of the present invention, and should not be regarded as the protection of the claims of the present invention Scope limitation.

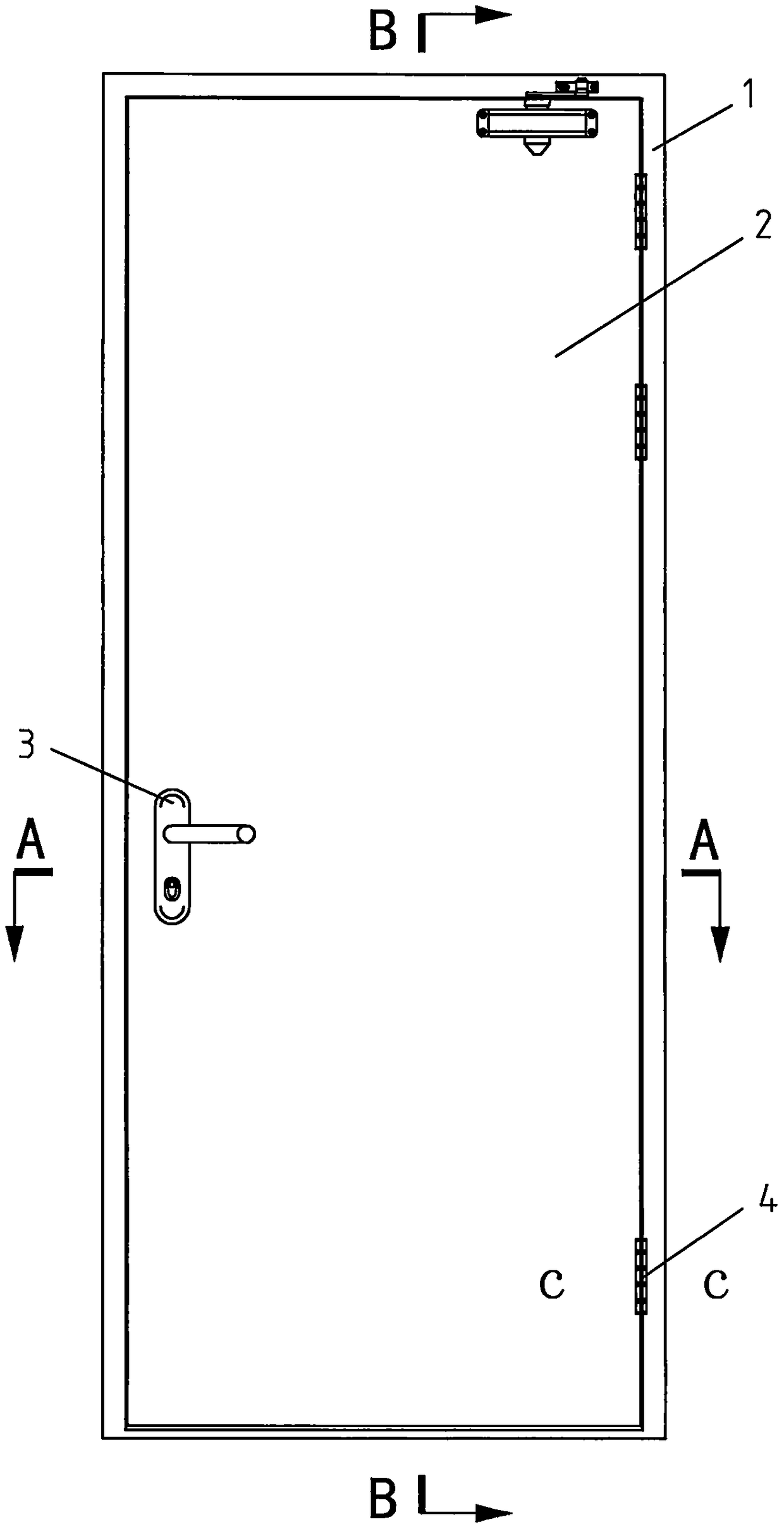

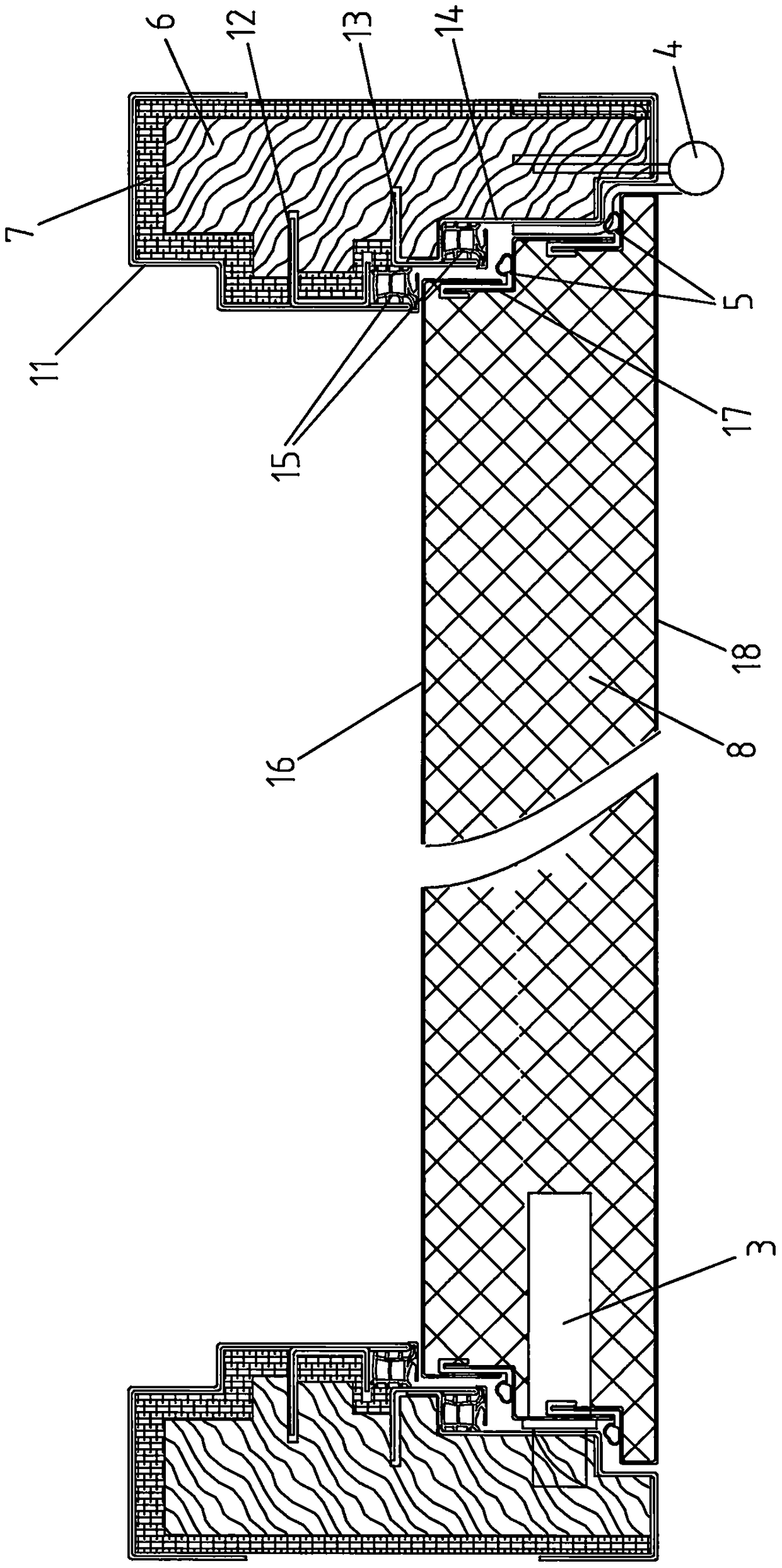

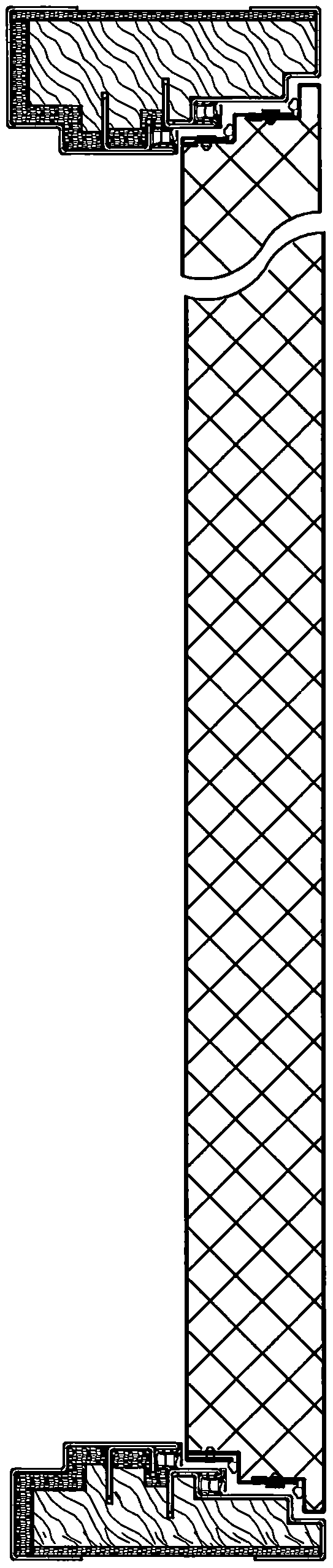

[0023] See Figure 1 to Figure 8 , the technical solution of the specific embodiment of the present invention is: comprise door frame 1 and door leaf 2, and door leaf 2 is provided with fireproof door lock 3, and door leaf 2 is connected with door frame 1 via hinge 4, above is the necessary structure of entrance door, The key is that the step-shaped mating surface of the door frame 1 and the door leaf 2 is equipped with a broken bridge structure. The above-mentioned step shape can make the door gap between the door frame 1 and the door leaf 2 bend, which increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com