Through casting side wall penetrating coring tool

A technology of passing casing and well wall, applied in casing, drill pipe, drilling equipment, etc., to achieve the effects of simple core coring construction, high coring yield, and strong formation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

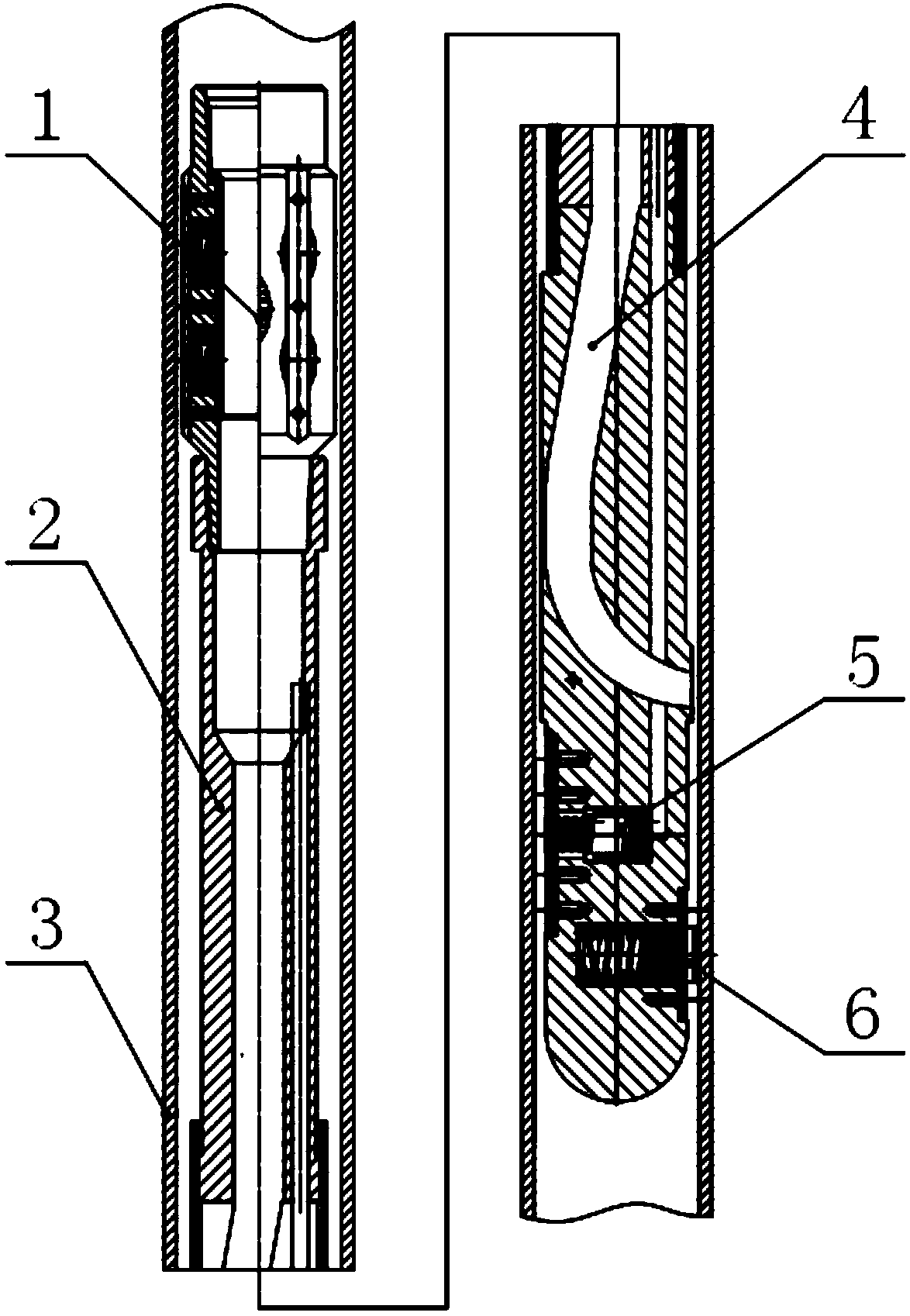

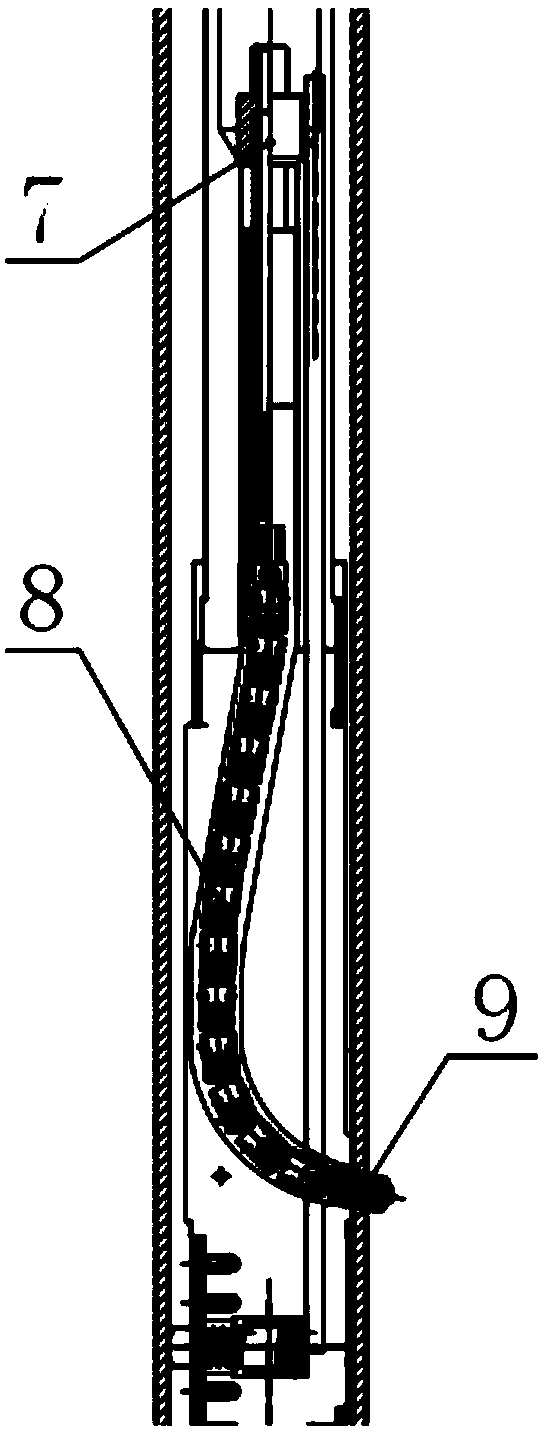

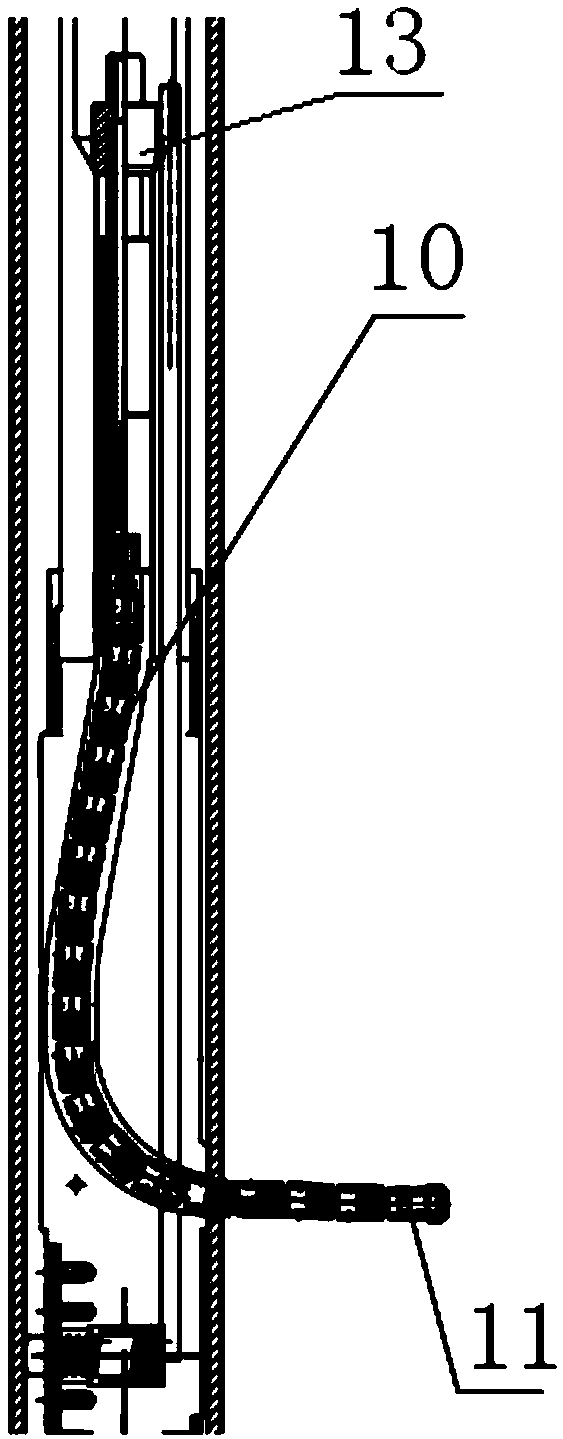

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a casing penetrating borehole wall coring tool includes a radial horizontal drilling guide mechanism; it also includes a casing window opening mechanism and a coring mechanism, and the radial horizontal drilling guide mechanism includes a hydraulic anchor 1 and a guide 4, the lower end of the hydraulic anchor 1 is connected to the guide 4 through the upper joint 2, and a sealing seat is designed on the inner wall of the upper joint 2 to provide a seal for the pressure of the oil pipe. A pusher 5 and a centralizing mechanism 6 are arranged on the side wall of the lower end of the guide 4, and the hydraulic anchor 1 can anchor the radial horizontal drilling guide mechanism on the inner wall of the casing 3. The connected track with curvature provides guiding function for the windowing universal joint 8 and the coring universal joint 10 . The pusher 5 can push the guider 4 so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com