Oil return control method and device for multi-line system, and computer storage medium

A multi-line system and oil return control technology, which is applied in refrigeration and liquefaction, refrigerators, compressors, etc., can solve the problem of large limitations in compressor oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

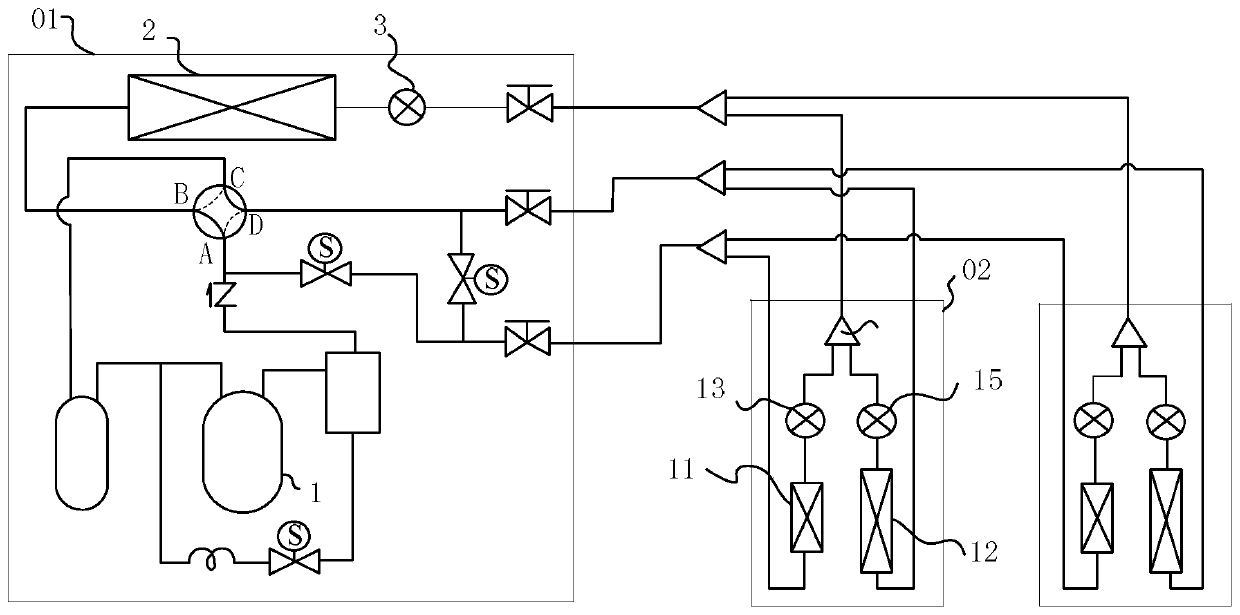

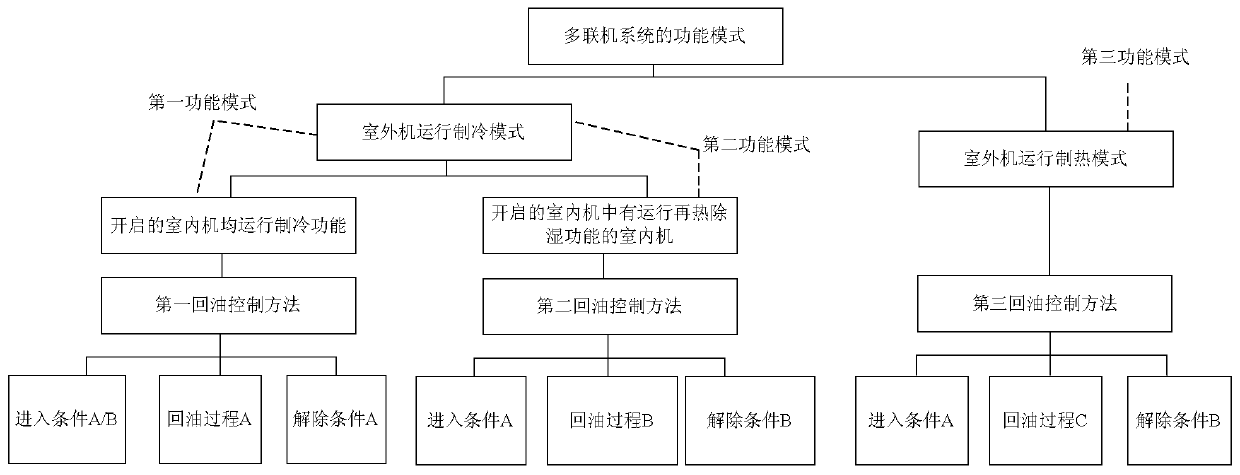

[0028] Combined with the above, when the multi-connected system runs in the first function mode, the outdoor unit operates in the cooling mode, and the outdoor heat exchanger acts as a condenser; the indoor units turned on in the multi-connected system all operate the cooling function, that is, the first heat exchanger and the second Both heat exchangers are used as evaporators. Therefore, when the multi-line system is running in the first functional mode, in the oil return control method provided by this embodiment, the oil return process includes adjusting the frequency of the compressor, respectively communicating with the first heat exchanger and the first heat exchanger as the evaporation heat exchanger. The opening degree EVR(n) of the first electronic expansion valve connected to the second heat exchanger, and the opening degree EVI(n) of the second electronic expansion valve. Optionally, the opening of the outdoor electronic expansion valve connected to the outdoor hea...

specific Embodiment 2

[0038] Combined with the above, when the multi-connected system is running in the second function mode, the outdoor unit operates in the cooling mode, and the outdoor heat exchanger acts as a condenser; among the indoor units that are turned on in the multi-connected system, there is an indoor unit that runs the reheating and dehumidifying function, and the second One heat exchanger acts as a condenser and the second heat exchanger acts as an evaporator. Therefore, when the multi-line system is running in the second function mode, in the oil return control method provided by this embodiment, the oil return process includes adjusting the frequency of the compressor and the second heat exchanger connected to the evaporation heat exchanger. The opening degree EVI(n) of the second electronic expansion valve. Optionally, the opening of the outdoor electronic expansion valve connected to the outdoor heat exchanger serving as the condensation heat exchanger is EVO(n)=EVO(n-1).

[00...

specific Embodiment 3

[0045] In combination with the foregoing, when the multi-split system is running in the third function mode, the outdoor unit is running in the heating mode, and the outdoor heat exchanger acts as an evaporator. In this case, the indoor units of the multi-split system can only include indoor units with heating function turned on, the first heat exchanger of which does not work and the second heat exchanger acts as a condenser. At this time, only adjustment is required during the oil return process. The opening degree EVO(n) of the outdoor electronic expansion valve connected as an evaporative heat exchanger. Or, the indoor units only include the indoor units with the heating function and the dehumidification function turned on. For the indoor units with the dehumidification function turned on, the first heat exchanger is used as the evaporator and the second heat exchanger is not working. At this time, the oil return process It is possible to adjust the opening degree EVO(n) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com