Integrated high-pressure air circuit contact piece and electrical connector

A high-pressure gas circuit and integrated technology, which is applied in the direction of contact manufacturing, fixed/insulated contact components, etc., can solve problems affecting gas transmission, leaking parts and interface sealing positions, etc., to achieve small size, meet the use requirements, strong resistance The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

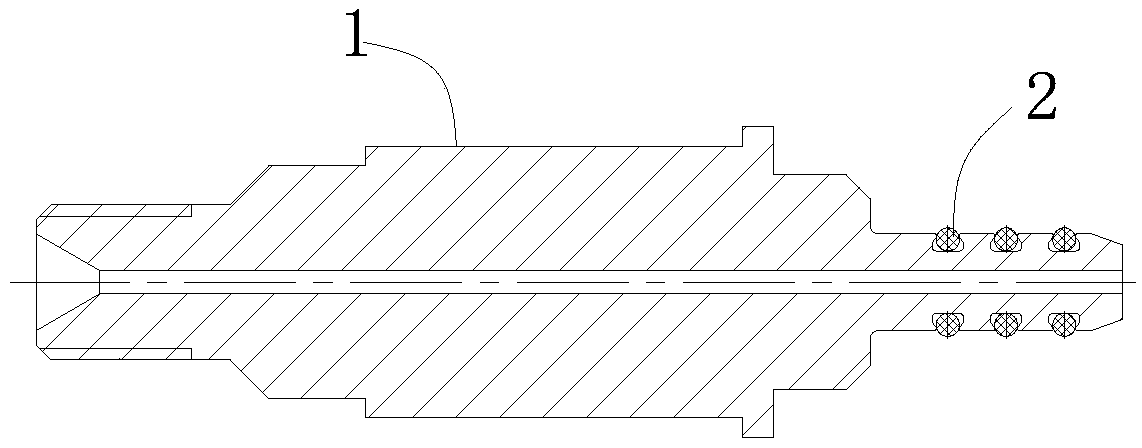

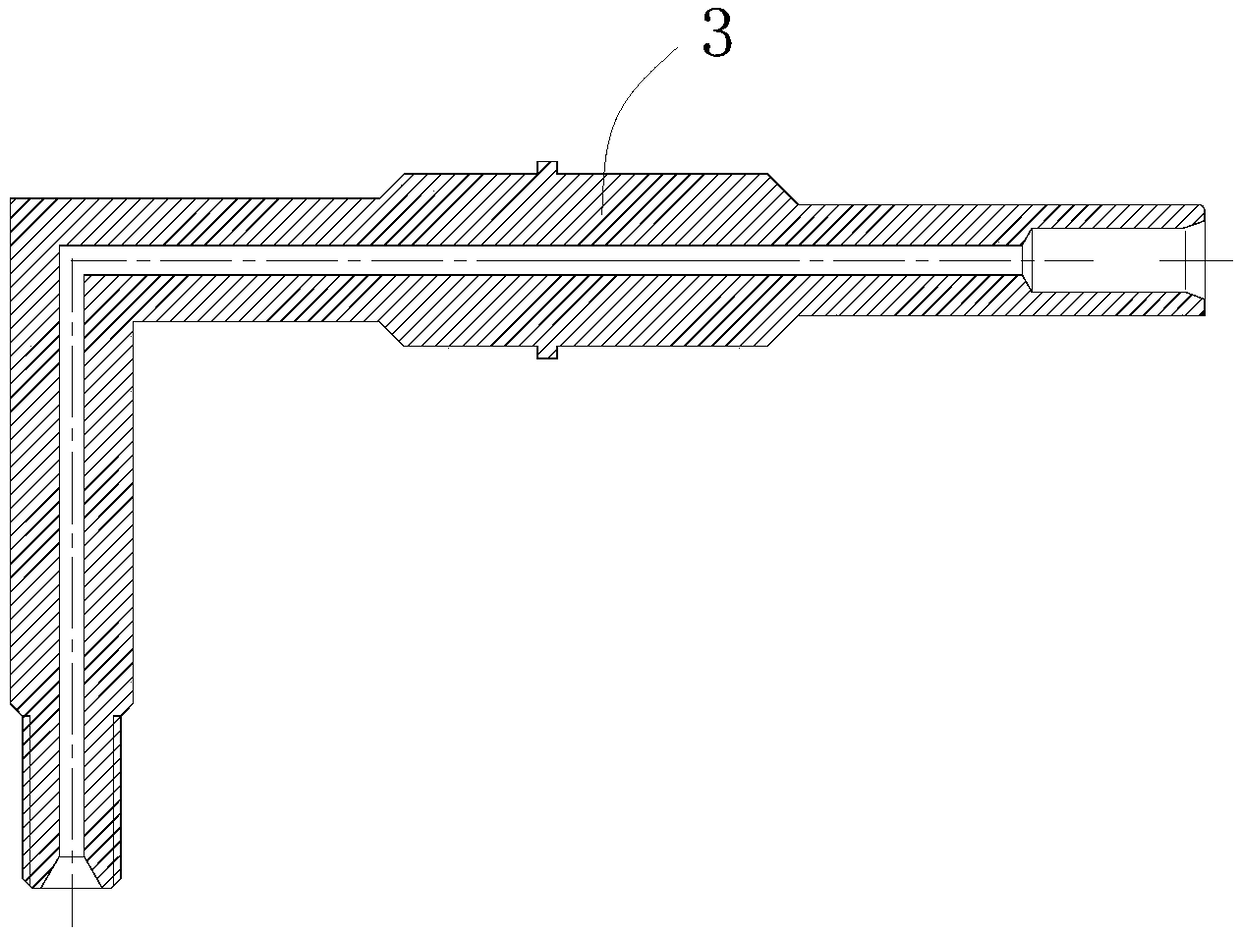

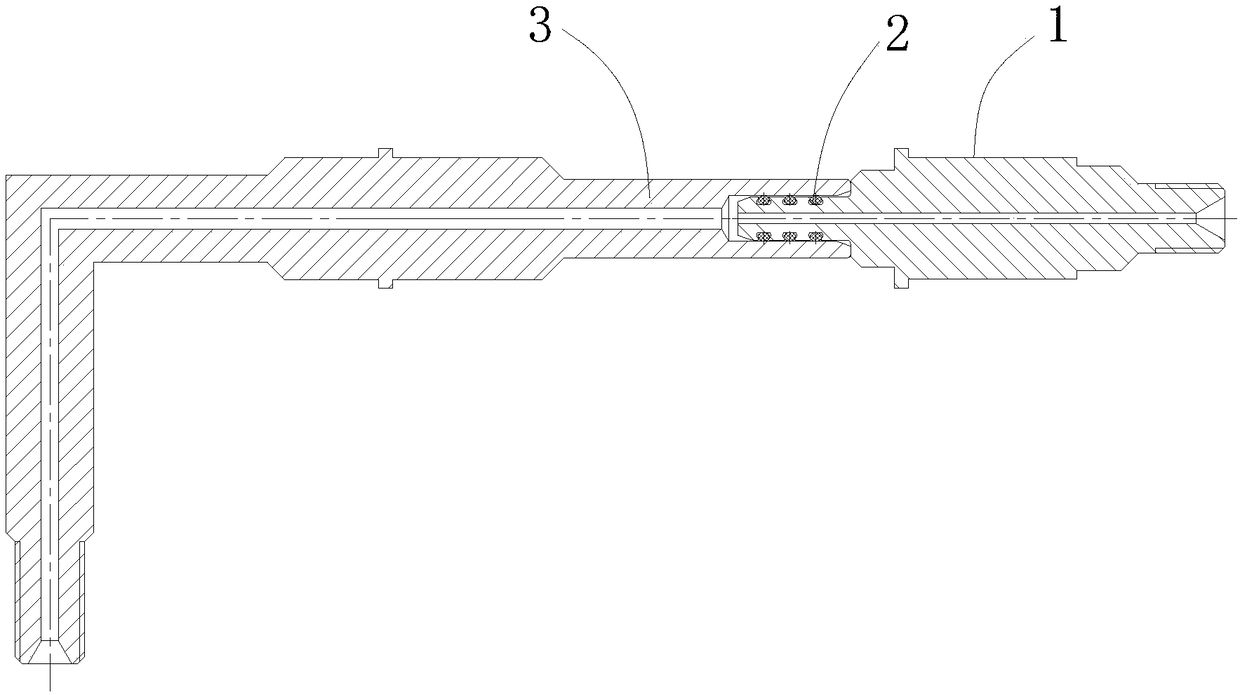

[0030] The embodiment part of the present invention provides a kind of preferred scheme, with reference to Figure 1-Figure 3 , this preferred embodiment provides an integrated high-pressure gas circuit contact, which includes a gas circuit socket 3 and a gas circuit pin 1 that are inserted into each other, wherein the gas circuit socket 3 is integrated Right-angle bent shape, and three O-shaped gaskets 2 are sheathed on the outside of the butt end of the gas channel pin 1 .

[0031] Three O-rings are equivalent to a three-layer seal. If one O-ring is damaged, the rest can still perform a good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com