Tower-shaped composite sleeve of ultrahigh-voltage cable terminal

A terminal tower type, composite casing technology, applied in the direction of cable terminals, etc., can solve the problems of excessive use of insulating oil, unable to solve the problem of icing, and the center is not stable enough, so as to increase the stability of the equipment, avoid ice flash, and reduce the center of gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

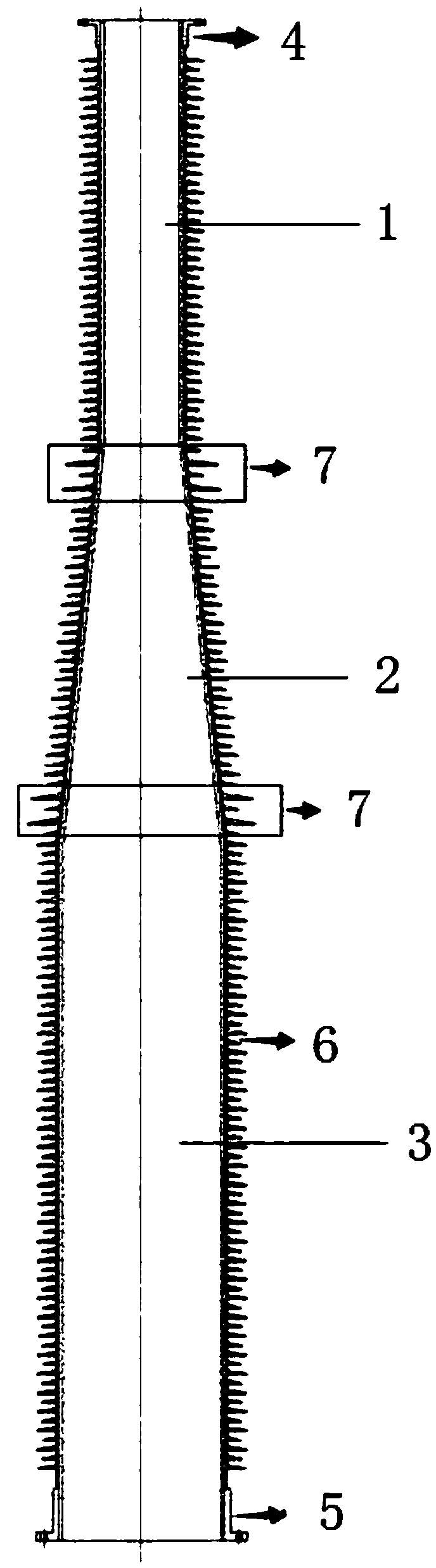

[0016] Such as figure 1 As shown, a tower-type composite bushing for an ultra-high voltage cable terminal, including a bushing body, is characterized in that the bushing body adopts a three-section tower structure, the lower section 3 is a first cylinder, and the middle section 2 is a cone The platform and the upper section 1 are the second cylinder, and the upper and lower parts of the casing body are respectively provided with upper fittings 4 and lower fittings 5, wherein the upper fittings 4 and the lower fittings 5 are used for casing body and upper and lower seals In connection with each other, the outer surface of the casing main body is provided with an umbrella skirt 6, and an anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com