High-frequency rotary transformer armature and winding fixing method thereof

A fixing method and technology of changing the armature, applied in the direction of windings, electric components, electrical components, etc., can solve the problems of easy loosening and falling out of the slot wedge, deformation of the slot, unable to reach the fixed coil, etc., and achieve better fixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

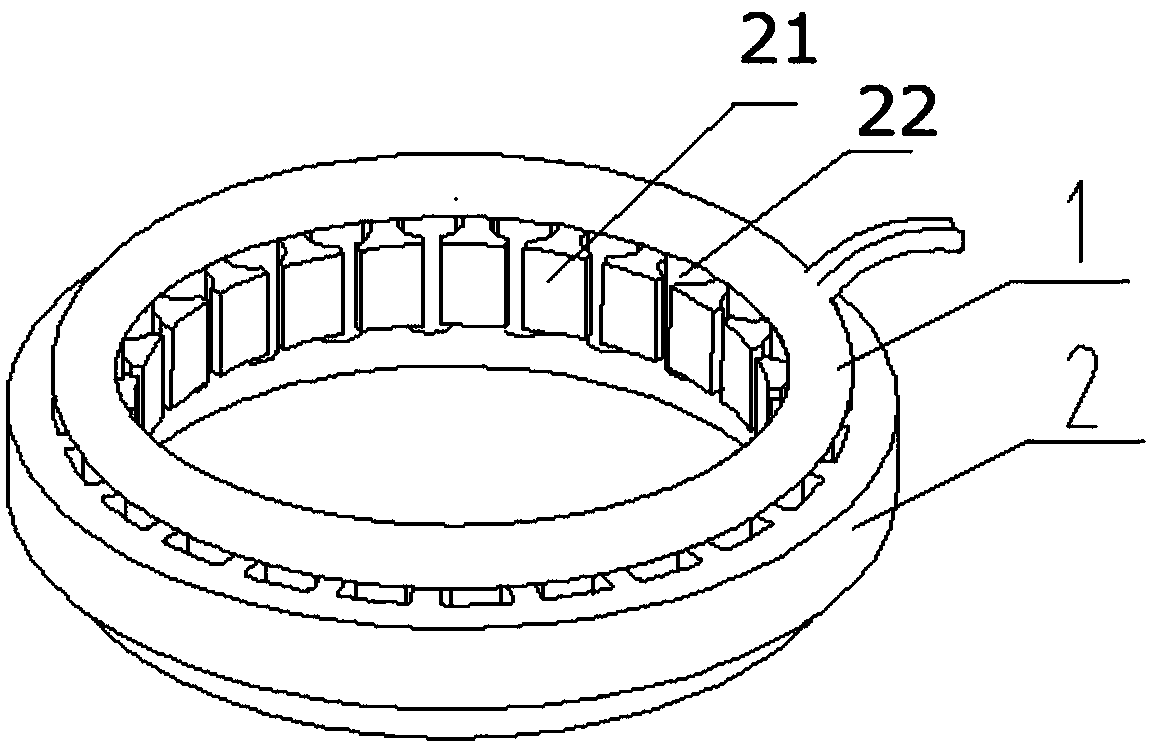

[0023] A high-frequency resolver armature winding, including a winding 1 and an iron core 2; a plurality of iron core teeth 21 are evenly fixed on the cup inner wall of the iron core 2, and tooth grooves 22 are processed between adjacent iron core teeth 21, The winding 1 is embedded in each tooth slot 22 , and the winding 1 is fastened by binding wires and fixed in the iron core 2 by binding wires.

[0024] The binding thread is cotton thread or silk thread.

[0025] A high-frequency resolver armature winding fixing method is fixed by binding wires, and the steps are:

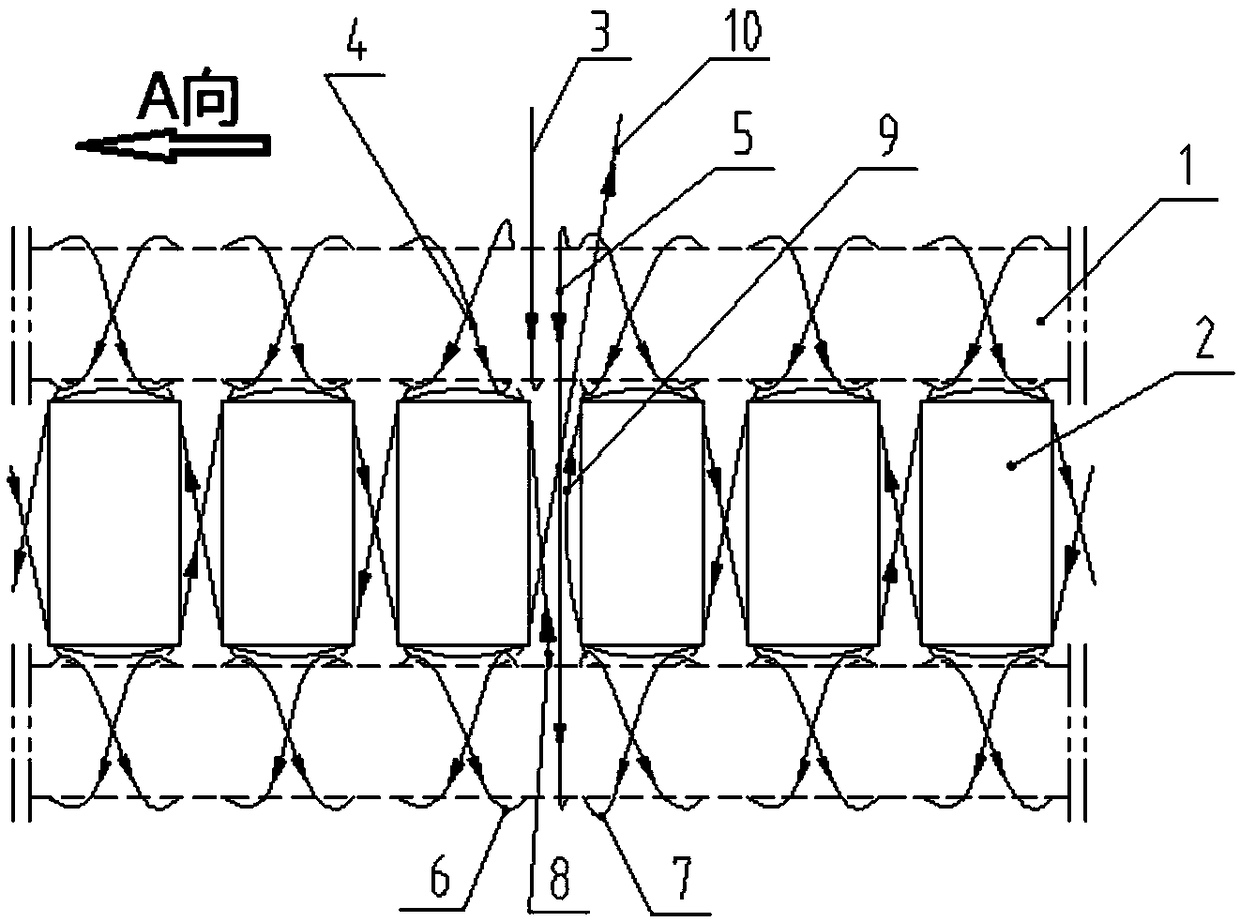

[0026] ①Use a binding wire to pass through the inner side of the winding adjacent to the tooth slot 22, and spirally wind the winding for a circle along the direction A of the current winding;

[0027] ②The binding wire turns to the reverse helical winding of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com