Pipe fitting extrusion forming device and automatic pipe fitting terminal machine using same

A technology for extrusion molding and extruding parts, which is applied in the field of automatic pipe fittings, can solve the problems of high production cost, high cost, complex structure, etc., and achieves the effects of low assembly cost, convenient operation and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

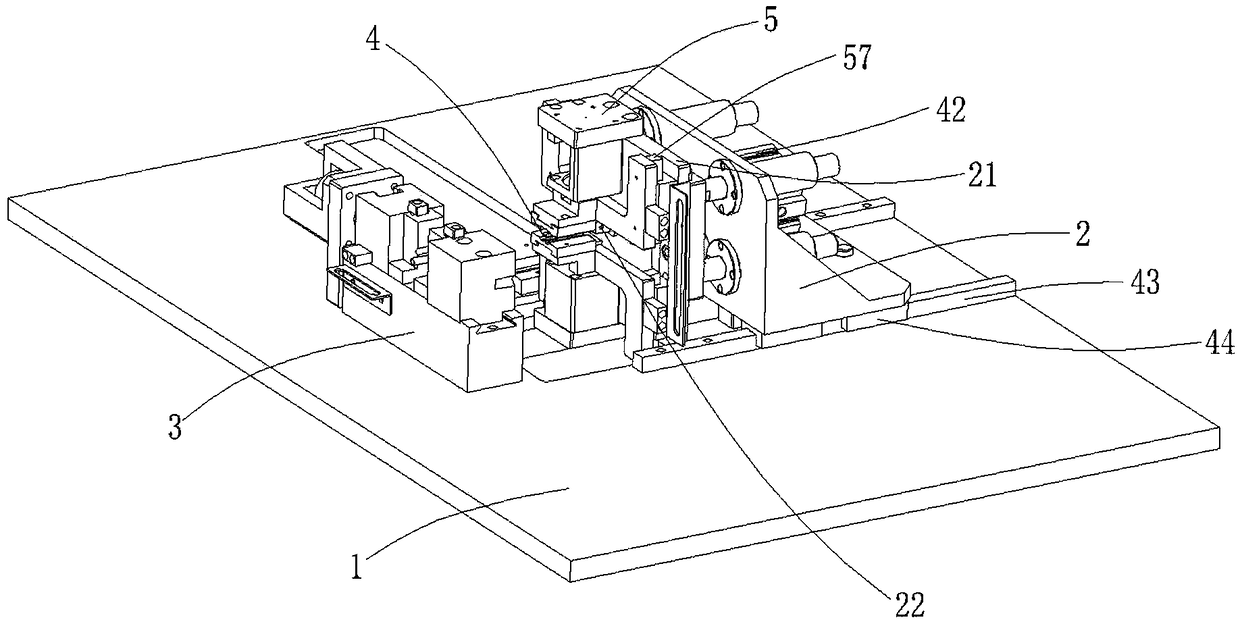

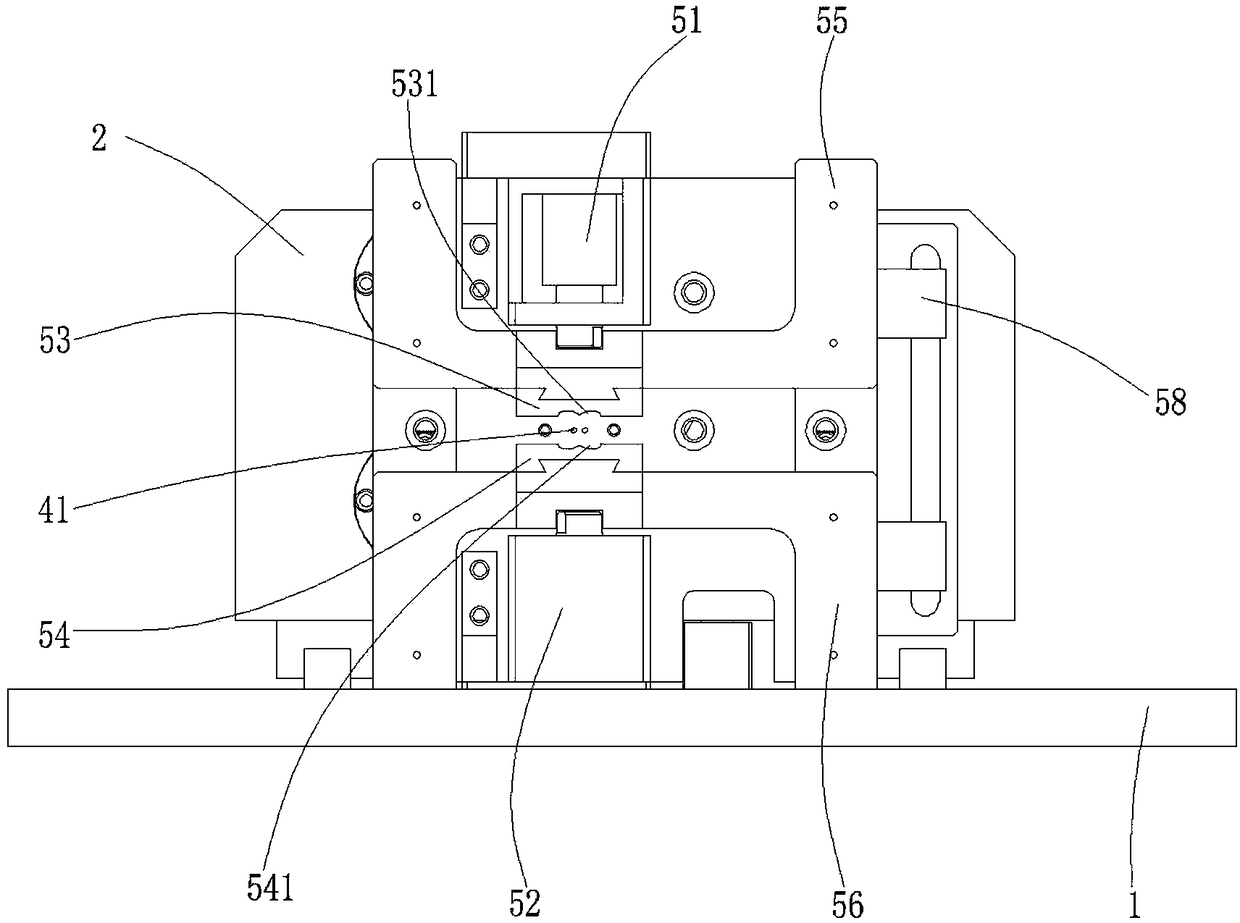

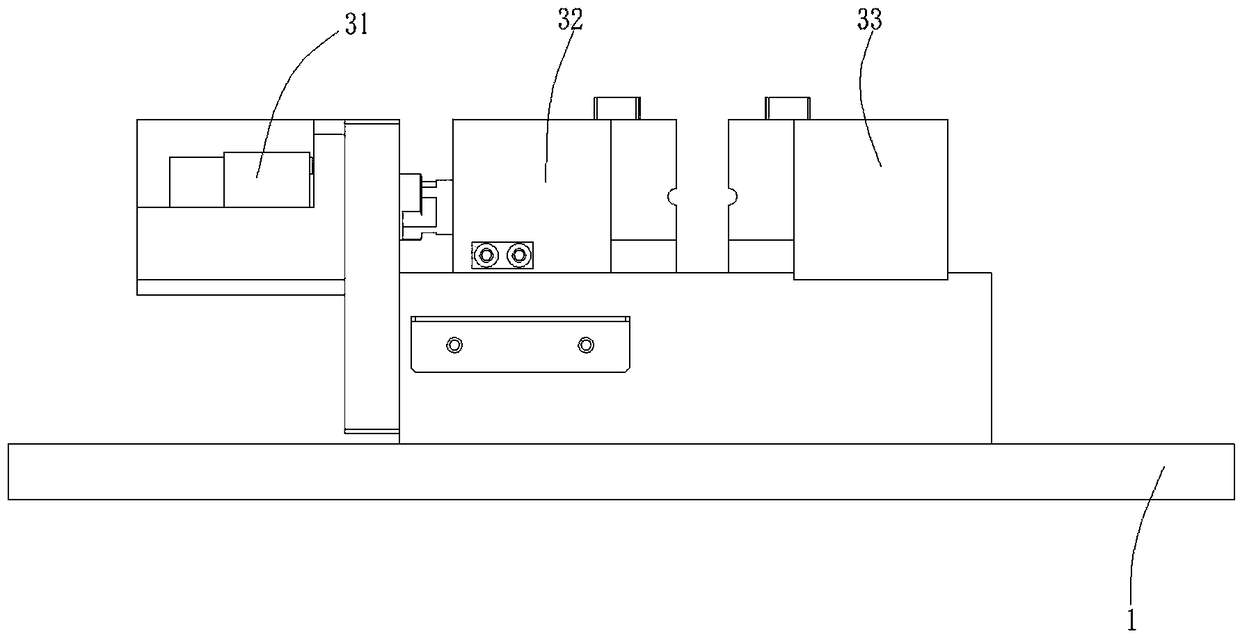

[0050] Embodiment one: if Figure 1-3As shown, a pipe fitting extrusion molding device provided in this embodiment may include: a frame (1), a moving bottom plate (2), a clamping part (3), a mandrel part (4), an extruding part (5 ), fixed plate (21), mandrel installation block (22), first drive mechanism (31), first compression block (32), second compression block (33), mandrel (41), second Driving mechanism (42), first slide rail (43), slide block (44), upper driving mechanism (51), lower driving mechanism (52), upper mold (53), lower mold (54), first slide plate ( 55), the second slide plate (56), the second slide rail (57), the detection block (58), the upper groove (531), the lower groove (541).

[0051] A frame (1), on which a movable bottom plate (2) is arranged, is used to fix and support all other components.

[0052] A clamping part (3), the clamping part (3) is arranged on the frame (1), and the clamping part (3) is used for clamping one end of the pipe.

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com