A helical antenna forming device

A molding device, a technology of helical antennas, applied in directions such as antennas and radiating element structures suitable for movable objects, can solve the problems of inability to guarantee the pitch and the diameter of the helix, and achieve accurate indicators in all aspects of the pitch, convenient use and operation, The effect that meets the needs of design and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

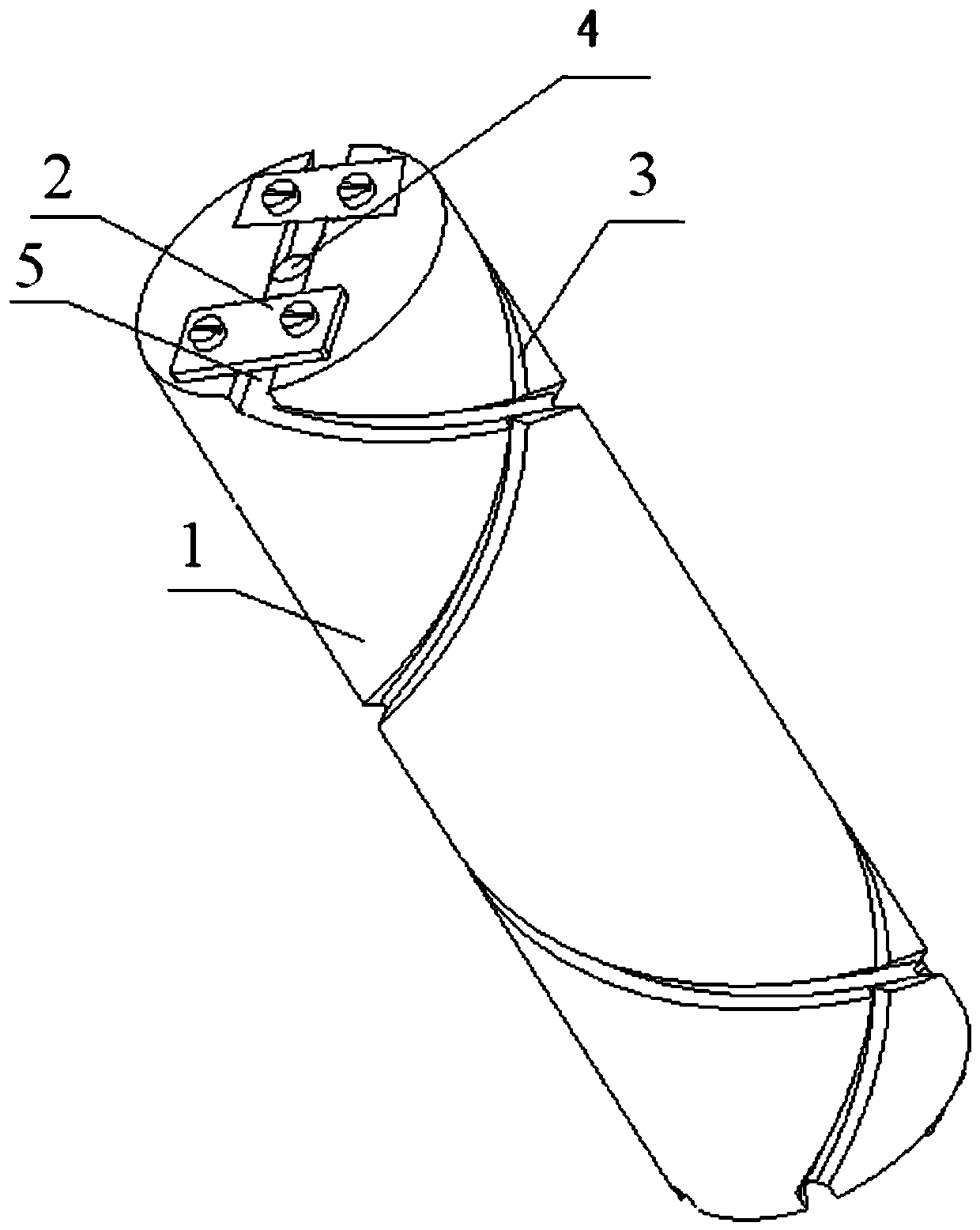

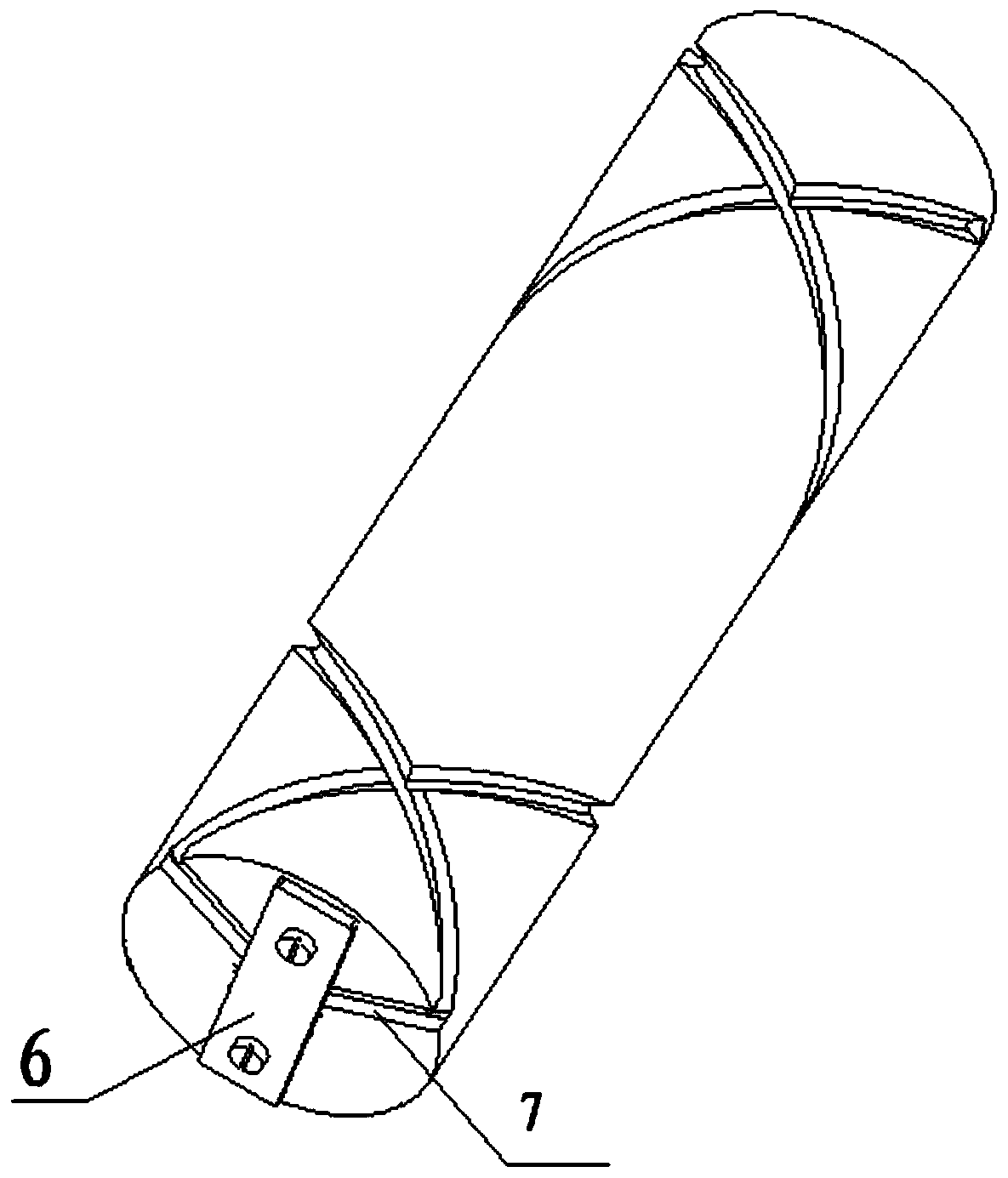

[0022] The present invention provides an effective and accurate spiral antenna forming device. According to the requirements for different welding diameters, lengths and directions of rotation of the spiral antenna, forming bodies 1 with different diameters are designed, and different directions of rotation and lengths are marked on the forming device of the spiral antenna. , and the forming positions of different pitches, to avoid product quality problems due to the strong stress of the antenna helix during the forming process of the helix antenna, and the amount of springback cannot be controlled, so as to achieve stable and accurate antenna helix state.

[0023] The spiral antenna forming device is composed of a forming main body 1, two front fixing plates 2 and a rear fixing plate 6, and the two front fixing plates 2 and the rear fixing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com